If you’ve ever faced challenges with barcode labeling, you’re not alone. The process can seem overwhelming, especially when the machines involved are unfamiliar. Understanding these machines is crucial to optimizing your production line.

The key to mastering barcode label production lies in knowing the roles each machine plays. Whether you’re printing, cutting, or applying labels, each step requires specialized equipment designed to streamline your operations and enhance accuracy.

Choosing the right equipment not only simplifies your workflow but also ensures that your products meet industry standards. Let’s delve into the essential machines that drive barcode label production.

Why Is the Barcode Label Machine the Heart of Your Production Line?

The barcode label machine is the cornerstone of any barcode labeling process. It is designed to handle everything from label printing to application, ensuring that each product is accurately labeled before leaving the production line. This machine is versatile and can be integrated into various stages of your production line, depending on your needs.

In our factory, we’ve seen firsthand how essential a reliable barcode label machine is. These machines are built to handle high volumes, maintain consistent print quality, and reduce errors. With advancements in automation, modern barcode label machines offer greater efficiency, reducing downtime and increasing output.

What Role Does a Barcode Label Printer Machine Play?

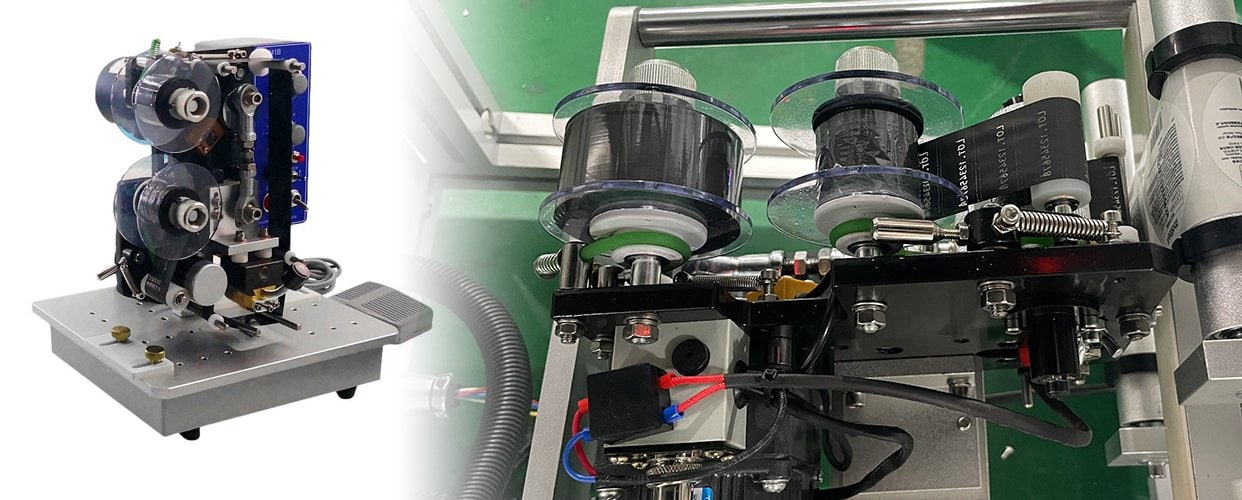

A barcode label printer machine is specialized for creating high-quality labels. These machines are engineered to print clear, scannable barcodes on a variety of materials. The quality of the print directly affects how easily the barcode can be scanned, making this machine critical in the production process.

Investing in a quality barcode label printer machine means ensuring that your barcodes are printed accurately and consistently. This reduces the risk of errors during scanning, which can lead to delays or issues in your supply chain. Our experience with these machines has shown that they are indispensable in maintaining the efficiency and reliability of your operations.

How Does a Barcode Label Applicator Machine Enhance Efficiency?

A barcode label applicator machine automates the process of applying labels to products. This machine is designed to handle various label sizes and shapes, making it versatile for different packaging needs. It ensures that labels are applied quickly and accurately, which is essential for maintaining product traceability and compliance with industry regulations.

In our operations, the barcode label applicator machine has been a game-changer. By automating the labeling process, we’ve significantly reduced manual labor and increased throughput. The precision of these machines also means fewer labeling errors, which translates to cost savings and improved product quality.

Why Is a Barcode Label Die Cutting Machine Important?

A barcode label die cutting machine is used to create custom shapes and sizes of labels. This machine is particularly important when your products require labels that fit specific dimensions or have unique shapes. The ability to customize labels ensures that your products stand out on the shelves and meet any regulatory requirements for labeling.

Our factory utilizes barcode label die cutting machines to produce labels that are not only functional but also aesthetically pleasing. This customization capability allows us to meet the specific needs of our clients, offering them a competitive edge in the market.

What Are the Benefits of Using a Barcode Label Maker Machine?

A barcode label maker machine combines the functions of printing and cutting labels. This all-in-one solution is ideal for businesses that need to produce custom labels in-house. The machine allows for quick adjustments to label designs, making it flexible and responsive to changing demands.

From our experience, a barcode label maker machine is an excellent investment for companies looking to take control of their labeling process. It offers flexibility, reduces reliance on external suppliers, and ensures that labels are produced to exact specifications.

How Does an Automatic Wire Labeling Machine Integrate with Barcode Labeling?

When it comes to labeling wires or cables, the automatic wire labeling machine plays a crucial role. This machine is designed specifically for applying labels to wires, which is an important aspect of many industries, including electronics and automotive manufacturing. Integrating this machine with your barcode labeling system ensures that all components, including wiring, are correctly labeled for easy identification.

Incorporating an automatic wire labeling machine into our production line has enhanced our ability to manage complex labeling tasks efficiently. This integration ensures that every part of the product, down to the wiring, is labeled and traceable, improving both safety and compliance.

How Does the Bottle Labeler Machine Fit into the Overall Process?

The Bottle labeler machine is essential for industries that require labeling on curved surfaces, such as bottles and containers. This machine is designed to apply labels smoothly and accurately on round or oval surfaces, ensuring that the labels adhere properly and are easy to read. Even for products like beverages or chemicals, this machine ensures that branding and regulatory information is clearly displayed.

We use bottle labeler machines in our factory to ensure that every product, regardless of its shape, is labeled to the highest standard. This machine’s precision helps us maintain brand consistency and meet industry regulations without compromising on speed or efficiency.

Conclusion

Choosing the right barcode labeling machines is essential for any business looking to optimize its production process. Each machine, from the barcode label printer to the bottle labler, plays a unique role in ensuring that your products are labeled accurately and efficiently. By investing in the right equipment, you can improve your production line’s efficiency, reduce errors, and maintain high standards of quality across your entire operation.