In the packaging industry, ensuring that every product has a properly applied label is crucial, especially for square bottles. These bottles present unique challenges due to their multiple flat surfaces and sharp corners. To tackle these challenges, specialized machines like square bottle wrap around labeling machines are designed to provide precise and efficient labeling solutions.

Square bottle wrap around labeling machines are engineered specifically to handle the complexities of applying labels to bottles with multiple surfaces, ensuring a perfect fit and professional finish every time. These machines are indispensable for businesses aiming to maintain high-quality standards in their packaging processes, especially when dealing with square-shaped containers.

Understanding the unique features and capabilities of these machines can help manufacturers choose the right equipment for their production needs. Let’s dive into what makes square bottle wrap around labeling machines stand out.

What is a Square Bottle Wrap Around Labeling Machine?

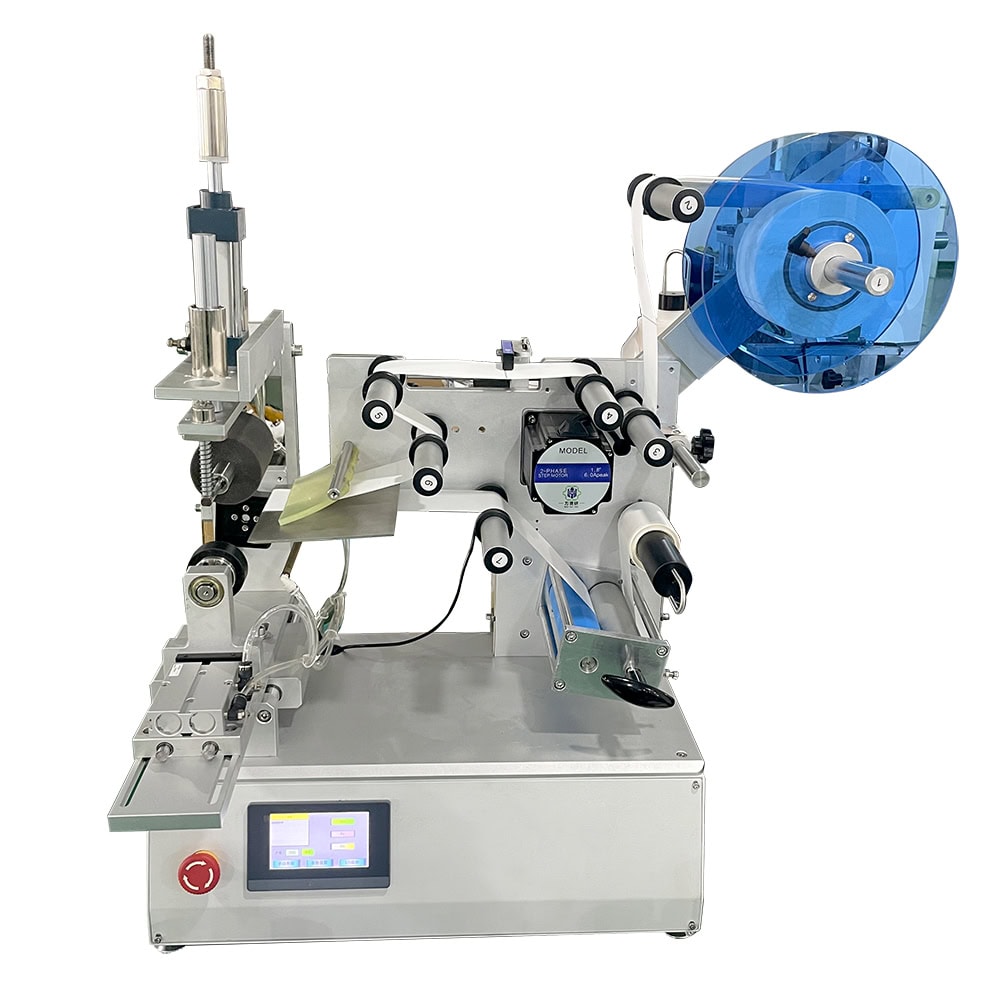

A square bottle wrap around labeling machine is a specialized piece of equipment designed to apply labels to square or rectangular bottles. Unlike standard labeling machines that are optimized for round bottles, these machines are engineered to handle the flat surfaces and edges of square bottles. This ensures that labels are applied smoothly and without wrinkles, regardless of the bottle’s shape.

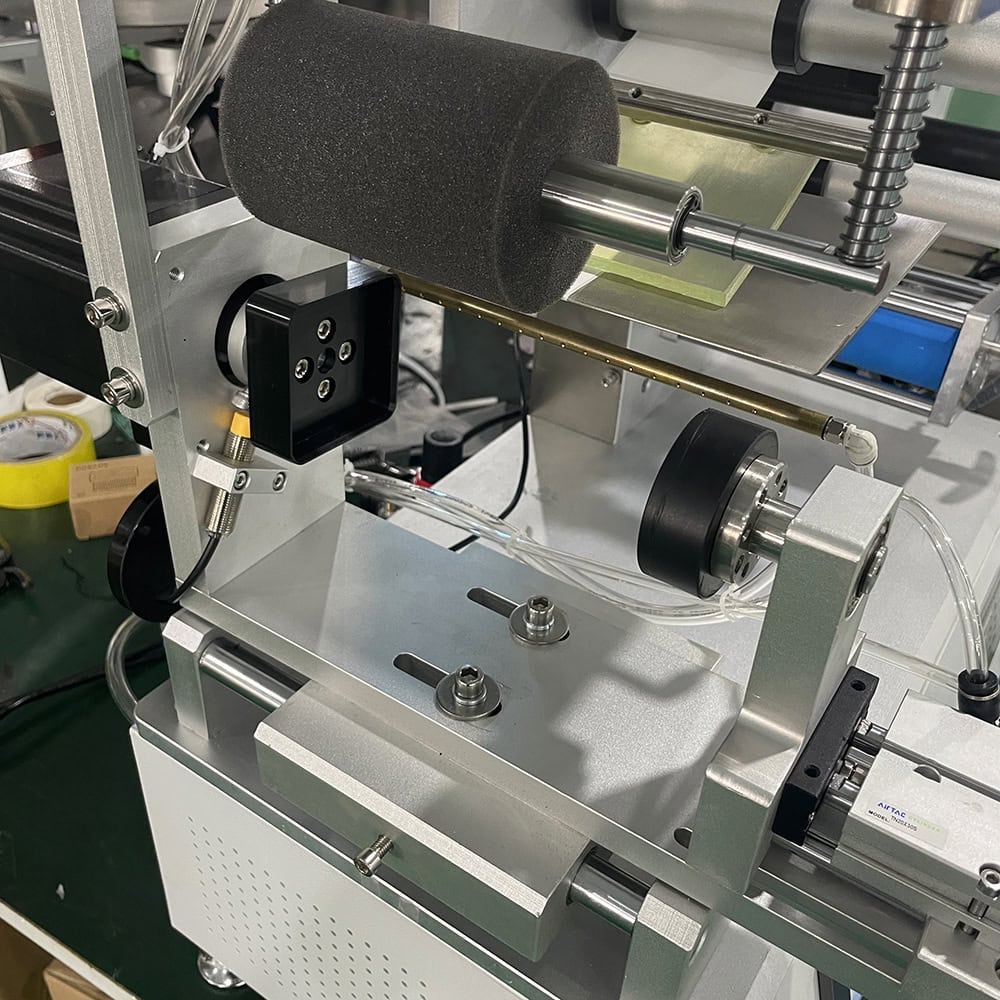

These machines use a combination of rollers, guides, and sensors to apply labels precisely, adjusting to the bottle’s dimensions and contours. This technology ensures that each label is correctly positioned and securely affixed, enhancing the product’s visual appeal and compliance with industry standards.

Key Features of Square Bottle Wrap Around Labeling Machines

Square bottle wrap around labeling machines come with several distinctive features that make them ideal for labeling multi-surfaced bottles. One of the primary features is their ability to handle bottles with multiple flat surfaces, ensuring that labels are applied uniformly across all sides. This is particularly important for products where branding and information must be visible from various angles.

Another key feature is the machine’s versatility. These machines can be adjusted to accommodate different bottle sizes and shapes, making them suitable for a wide range of products. Additionally, they are equipped with advanced sensors and control systems that ensure labels are applied with precision, reducing waste and improving efficiency.

Moreover, square bottle wrap around labeling machines are designed for high-speed operation, making them suitable for both small and large-scale production environments. This ensures that manufacturers can maintain productivity without compromising on label quality.

Automatic vs. Semi-Automatic: Which is Better?

When choosing between automatic and semi-automatic square bottle wrap around labeling machines, it ultimately depends on your production needs. Automatic machines are ideal for large-scale operations where speed and efficiency are paramount. These machines can be integrated into existing production lines, allowing for seamless, continuous labeling with minimal human intervention.

On the other hand, semi-automatic machines are better suited for smaller operations or startups. They offer a balance between cost and functionality, providing the necessary labeling capabilities without the higher investment required for fully automatic systems. For businesses with lower production volumes, semi-automatic machines can be a cost-effective solution that still delivers professional results.

How to Choose the Right Square Bottle Wrap Around Labeling Machine for Your Product

Selecting the right square bottle wrap around labeling machine involves considering several factors. First, you need to assess the size and shape of your bottles. Machines vary in their ability to handle different dimensions, so it’s crucial to choose one that can accommodate your specific bottle types.

Next, consider your production volume. If you operate a high-volume production line, an automatic labeling machine might be more suitable due to its speed and efficiency. However, for lower volumes, a semi-automatic machine might suffice, offering flexibility and lower operating costs.

Lastly, think about the integration capabilities. If you plan to scale your operations, choosing a machine that can easily integrate with other packaging equipment will be beneficial in the long run.

Can the Power Supply Adapt to Different Countries’ Standards?

One of the concerns when purchasing a labeling machine for international use is whether it can adapt to different power standards. Fortunately, most modern square bottle wrap around labeling machines are designed with flexible power supply options. Manufacturers often provide customization services to adjust the machine’s power requirements to match the standards of different countries.

This means that whether you’re operating in North America, Europe, or Asia, your machine can be configured to meet local power specifications, ensuring safe and efficient operation. It’s always advisable to discuss your specific needs with the manufacturer to ensure the machine you purchase is fully compatible with your operational environment.

Can It Also Handle Round Bottle Labeling?

A common question that arises is whether a square bottle wrap around labeling machine can also handle round bottles. The good news is that many of these machines are versatile enough to be adjusted for round bottle labeling. With slight modifications, such as changing the roller settings or label application parameters, these machines can effectively label round bottles as well.

However, it’s important to consult with technical experts to ensure the machine is properly configured for this dual functionality. Making the necessary adjustments will ensure that the machine performs optimally for both square and round bottles, providing flexibility in your production line.

Can It Handle Multiple Sizes of Square Bottles?

One of the advantages of square bottle wrap around labeling machines is their ability to handle multiple sizes of square bottles. These machines are designed with adjustable components that can be fine-tuned to accommodate different bottle dimensions. This feature is particularly useful for manufacturers who produce a variety of products in different packaging sizes.

However, there are limitations when the size differences between bottles are significant. In such cases, it might be necessary to use additional attachments or customize the machine to ensure optimal performance across all bottle sizes.

How to Customize a Square Bottle Wrap Around Labeling Machine?

Customizing a square bottle wrap around labeling machine to meet specific production needs is a straightforward process. Start by identifying the unique requirements of your product line, such as bottle size, label type, and production speed. Then, work with the manufacturer to tailor the machine’s features accordingly.

Customization options may include adjustments to the label application mechanism, integration with existing production lines, or even modifications to the machine’s power supply to meet international standards. By collaborating closely with the manufacturer, you can ensure that the final product is perfectly suited to your operational needs.

Challenges of Labeling Square Bottles

Labeling square bottles comes with its own set of challenges, primarily due to the bottle’s shape. The flat surfaces and sharp corners can make it difficult to apply labels smoothly and without wrinkles. Traditional labeling machines, designed for round bottles, may struggle with these requirements, leading to misaligned or poorly adhered labels.

The demand for high-quality labeling on square bottles is increasing, especially in industries where branding and product information are crucial. As a result, manufacturers are seeking specialized solutions that can address these challenges effectively.

How Wrap Around Labeling Machines Address These Challenges

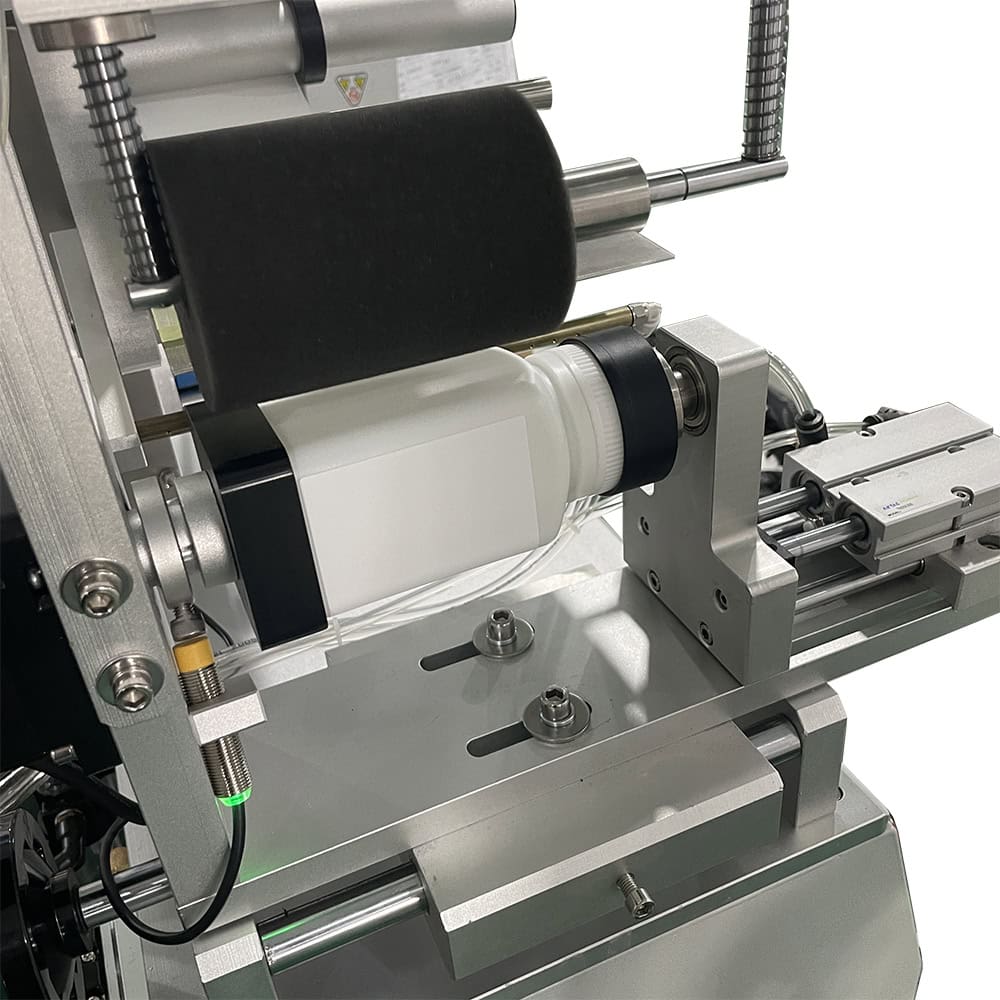

Wrap around labeling machines are specifically designed to tackle the challenges of labeling square bottles. These machines use advanced technology to ensure that labels are applied with precision, even on bottles with multiple surfaces. By adjusting the label application mechanism and using sensors to detect bottle orientation, these machines can achieve a perfect fit every time.

Furthermore, these machines can control the pressure applied to the labels, ensuring they adhere tightly to the bottle’s surface, including around corners. This level of precision helps to eliminate common issues like air bubbles or misalignment, ensuring that every bottle looks professional and meets industry standards.

Conclusion

wrap around label machines are essential for businesses looking to improve their labeling processes, especially for square bottles. Whether you opt for an automatic or semi-automatic machine, it’s important to choose equipment that matches your production needs and can handle the unique challenges presented by square bottles. By investing in the right machine and working with reputable automatic labeling machine manufacturers, you can enhance your production efficiency and product presentation.