Choosing between thermal and pressure-sensitive labeling machines can be confusing. Misjudging the right machine leads to wasted resources and poor labeling results. The right solution depends on understanding the key differences and applications of each machine.

The main difference between thermal and pressure-sensitive labeling machines is their labeling process. Thermal machines use heat to apply labels, while pressure-sensitive machines rely on adhesive activation through pressure. Both have unique advantages based on speed, material, and industry application.

Understanding these differences helps businesses optimize their labeling process.

What Is a Thermal Labeling Machine?

Thermal labeling machines apply labels using heat. The two main types are direct thermal and thermal transfer. Direct thermal technology uses heat-sensitive paper that darkens when heated, making it ideal for short-term labels, such as shipping labels or receipts. Thermal transfer, on the other hand, uses a ribbon to transfer ink onto the label surface, creating a durable label that can withstand various environmental conditions.

- Advantages: Thermal labeling machines are cost-effective for short runs, especially in industries where quick, temporary labels are needed. They eliminate the need for ink or toner in direct thermal printing, which reduces operating costs.

- Limitations: Direct thermal labels tend to fade over time, especially when exposed to heat or light. While thermal transfer offers better durability, it requires ribbons, which adds to the cost and complexity of the labeling process.

Thermal labeling machines are widely used in retail, logistics, and food packaging where the need for high-volume, low-cost labeling is crucial. The machines pair well with systems like barcode printers for efficient operations.

What Is a Pressure-Sensitive Labeling Machine?

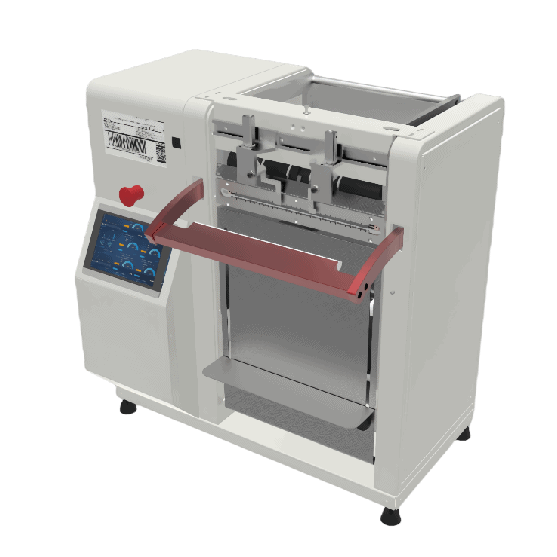

Pressure-sensitive labeling machines apply labels using pre-applied adhesive that is activated by pressure. These machines are highly versatile and suitable for a range of materials, including plastic, glass, metal, and more. Pressure-sensitive labels are commonly used in industries such as pharmaceuticals, beverages, and automotive products due to their ability to adhere to irregular surfaces.

- Advantages: Pressure-sensitive machines are known for their speed and adaptability. They can handle a wide variety of label types, including paper, film, and foil. These machines are also capable of handling high-volume operations efficiently.

- Limitations: The adhesive on pressure-sensitive labels may degrade over time, especially if not stored properly. Additionally, the upfront cost for pressure-sensitive labeling systems tends to be higher due to the complexity of adhesive mechanisms and the need for precise application.

Pressure-sensitive labeling is ideal for products that require consistent, high-quality labels, like those produced by a Flag Labeling Machine or a Flat Labeling Machine.

Key Differences Between Thermal and Pressure Labeling Machines

- Labeling Process: Thermal machines use heat to apply labels, either directly onto the label material (direct thermal) or through a ribbon (thermal transfer). Pressure-sensitive machines use adhesive-backed labels that require pressure for application.

- Materials: Thermal labeling systems often require heat-sensitive or ribbon-compatible materials, while pressure-sensitive machines can handle a broader range of label materials and surfaces.

- Label Durability: Thermal transfer labels, especially, are highly durable and ideal for long-lasting labeling needs in harsh environments. Pressure-sensitive labels are flexible and suitable for a wide range of products but may be less durable over time depending on the adhesive.

- Cost: Thermal labeling is often more affordable for short runs, especially for applications like shipping or food labels. Pressure-sensitive machines, on the other hand, can have higher initial setup costs due to the adhesive mechanisms but offer faster speeds and adaptability for diverse labeling needs.

- Speed: Pressure-sensitive labeling machines generally operate at faster speeds, making them the better choice for high-volume production environments like packaging and bottle labeling.

Application Industries

Thermal Labeling Machines

Thermal labeling is commonly used in industries that require short-term, cost-effective labeling. For instance, logistics companies often use industrial label printers for shipping labels, while retail businesses may use them for price tags. Direct thermal machines are preferred for temporary labels, while thermal transfer machines are used for products that need more durability, such as in healthcare and electronics.

Pressure-Sensitive Labeling Machines

Pressure-sensitive machines are found in industries like pharmaceuticals, beverages, and automotive parts. These machines are frequently paired with customized labeling machines to meet the specific needs of products with irregular surfaces or complex packaging designs. Pressure-sensitive labels are ideal for flexible applications and are commonly used in sectors where speed and precision are key, such as in bottle filling and packaging.

Maintenance and Operating Costs

Thermal labeling machines generally have lower maintenance requirements because they lack the adhesive systems that pressure-sensitive machines use. However, the need for ribbons in thermal transfer printing can add to the operational cost. Pressure-sensitive machines, while fast and versatile, require regular maintenance to ensure the adhesive systems function correctly, particularly for high-speed operations.

For industries like beverage production, which rely on high-volume output, the cost of operating pressure-sensitive labeling machines may be offset by the speed and efficiency they provide, especially when combined with other machines such as bottle capping machines and filling machines.

Environmental Considerations

Thermal labeling, especially direct thermal, can be more environmentally friendly since it uses fewer consumables like ribbons or adhesives. This makes it a preferred choice for businesses aiming to reduce waste. However, thermal labels, particularly those printed using direct thermal technology, are less durable and may require more frequent reprinting.

Pressure-sensitive labeling, while more durable, often uses adhesives that can complicate recycling efforts. For businesses looking to reduce their environmental footprint, choosing eco-friendly adhesives or recycling-compatible label materials can help mitigate these issues.

Conclusions

Choosing between thermal and pressure-sensitive labeling depends on your product, industry, and labeling requirements. Understanding these key differences ensures better labeling efficiency and cost management.