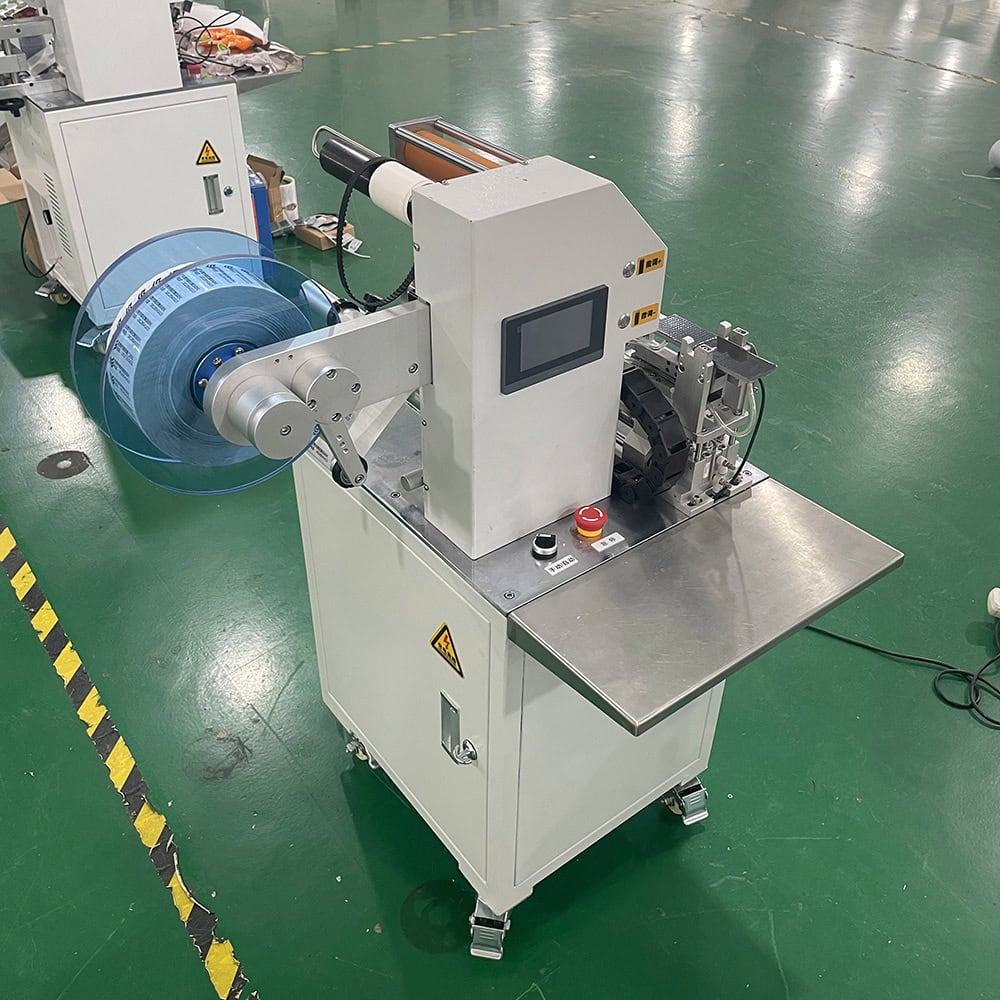

Many buyers struggle to find a high-quality wire harness flag labeling machine at an affordable price, often feeling overwhelmed by complex pricing and various options.

Overpaying for a labeling machine can lead to reduced profitability, while choosing the wrong machine can result in operational inefficiencies and higher maintenance costs.

This article outlines the best strategies to help you secure the lowest price for a wire harness flag labeling machine without compromising on quality or performance.

Why Price Isn’t Everything: Balancing Cost and Quality

When sourcing a wire harness flag labeling machine, it’s essential to understand that price should not be the only determining factor. While it’s tempting to go for the lowest bid, opting for the cheapest option could mean sacrificing durability, precision, or compatibility with other systems. A well-constructed machine that offers high efficiency and fewer breakdowns could save you significant costs in the long run.

Key features to consider include labeling precision, speed, ease of integration with your existing systems, and after-sales support. These factors contribute to the overall cost-effectiveness of the machine. For example, a bottle labeling machine with higher accuracy might cost more upfront but will save you money by reducing waste and re-labeling errors.

Clarifying the Functions You Need to Reduce Unnecessary Configurations

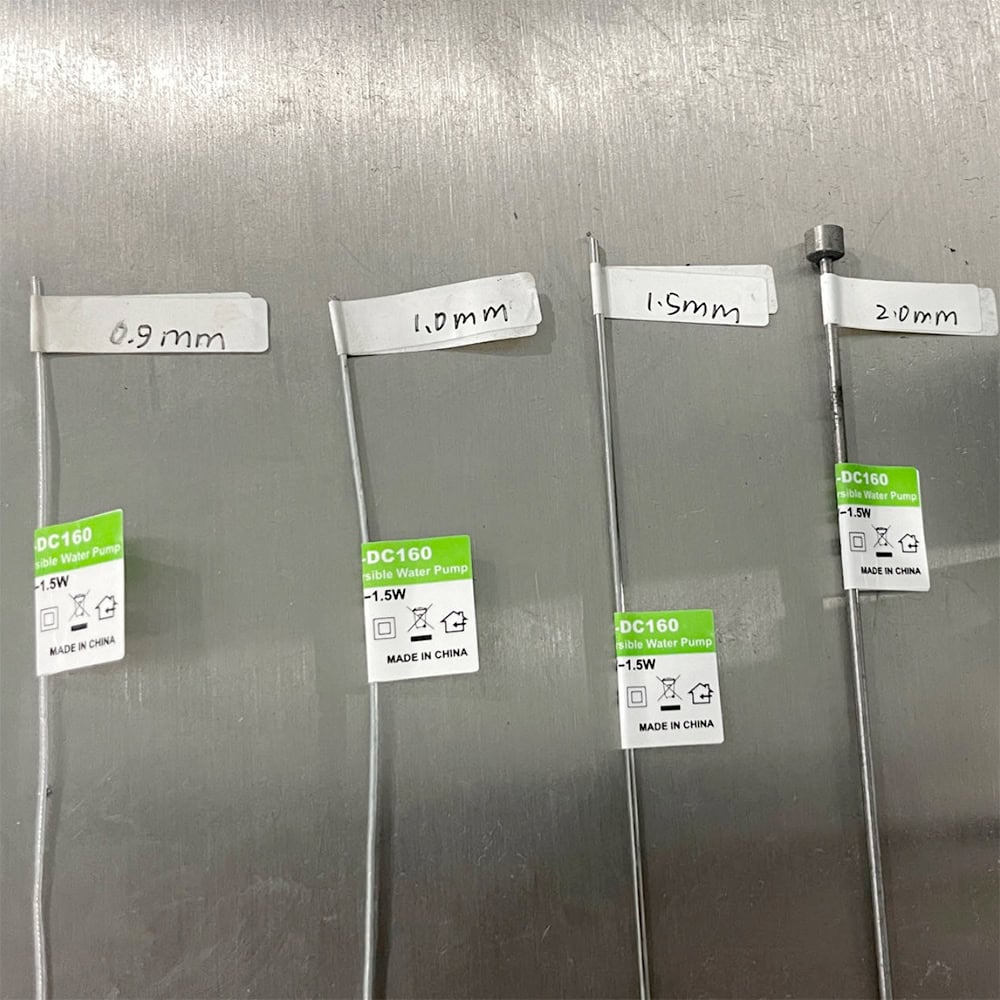

To secure the best price, it’s crucial to clarify the functions your wire harness flag labeling machine needs. Avoiding unnecessary features can significantly reduce the cost. For instance, some machines are equipped with a label printer, but if your operation requires only basic labeling, there’s no need to invest in a printer, as it can add unnecessary costs.

Similarly, designing a labeling mechanism with complex compatibility features might drive the price up unnecessarily. If your product is simple and falls within the range of standard labeling, a basic setup can suffice, saving you money. Understanding the exact requirements for your machine will prevent you from paying for additional capabilities that won’t be used in your production line.

Negotiating with Manufacturers for Better Deals

Building strong relationships with manufacturers can play a significant role in securing a lower price for your machine. Communication is key—clearly state your needs and expectations, and be open to negotiation. Many suppliers are willing to offer discounts or better payment terms if you are a repeat customer or commit to a long-term business relationship.

Another negotiation tactic is to request bundled offers. For example, if you need a vacuum packaging machine or a shrink wrap machine in addition to your labeling machine, ask if the supplier can offer a discount for purchasing multiple pieces of equipment at once. Additionally, if you have specific shipping preferences, negotiating these terms upfront can prevent unexpected charges that increase the overall cost.

Evaluating Supplier Reputation and Reviews

The reputation of the manufacturer is vital to ensure you are getting value for your money. Be sure to check reviews from other buyers who have purchased similar packaging machines or filling machines from the supplier. Their experiences can provide valuable insights into the quality of the machine and the reliability of the supplier.

Also, look for certifications and quality control processes that the manufacturer follows. A reputable supplier will have clear documentation regarding the testing and quality assurance measures for their products. This helps reduce the risk of receiving a faulty machine that could cause operational delays and additional costs.

Considering Alternative Manufacturing Locations

Manufacturers from different regions may offer varying price points. While sourcing from low-cost countries like China or Vietnam often provides cost advantages, it’s important to assess the trade-offs, such as shipping costs, delivery times, and potential language barriers. For instance, if you’re looking for a customized labeling machine, some manufacturers in regions with lower labor costs may offer more flexibility and customization at a lower price compared to those in higher-cost countries.

However, don’t let lower prices lead you to overlook quality. Always evaluate the total cost of ownership, including shipping, taxes, and customs fees, which can quickly add up and affect the overall value of your purchase.

Utilizing Industry Connections and Trade Shows

Attending industry trade shows is an excellent way to network with suppliers and discover exclusive discounts on labeling machines. Many manufacturers offer special pricing during these events to attract buyers. You can also use trade shows to compare different products and identify the most cost-effective options for your needs.

Building connections at trade shows can help you stay informed about new offerings and pricing changes, as well as give you direct access to sales representatives who can offer personalized deals.

Optimizing Payment Terms to Save Costs

Negotiating payment terms can lead to significant savings. Suppliers often provide more competitive pricing when you agree to flexible payment terms. For instance, offering to pay a portion upfront and the remainder upon delivery can give you leverage to negotiate a lower price. In some cases, offering cash upfront may allow you to secure a discount on the total cost.

Additionally, consider the benefits of using low-fee payment methods like bank transfers instead of credit cards, which may incur higher processing fees. Choosing the right payment method can help you save additional costs in the purchasing process.

Ensuring After-Sales Support and Warranty Coverage

One factor often overlooked when negotiating the price of a wire harness flag labeling machine is the cost of after-sales service and warranty coverage. A low purchase price might seem attractive, but if the machine requires frequent repairs or lacks support, the long-term cost can add up. Ensure that the supplier offers a solid warranty, as well as ongoing maintenance or technical support.

Also, be aware of potential hidden costs, such as shipping fees for repairs, parts replacement, or machine downtime, which can all affect your overall expenses. Some suppliers offer comprehensive service packages that can be worth the extra investment if it means fewer disruptions to your production line.

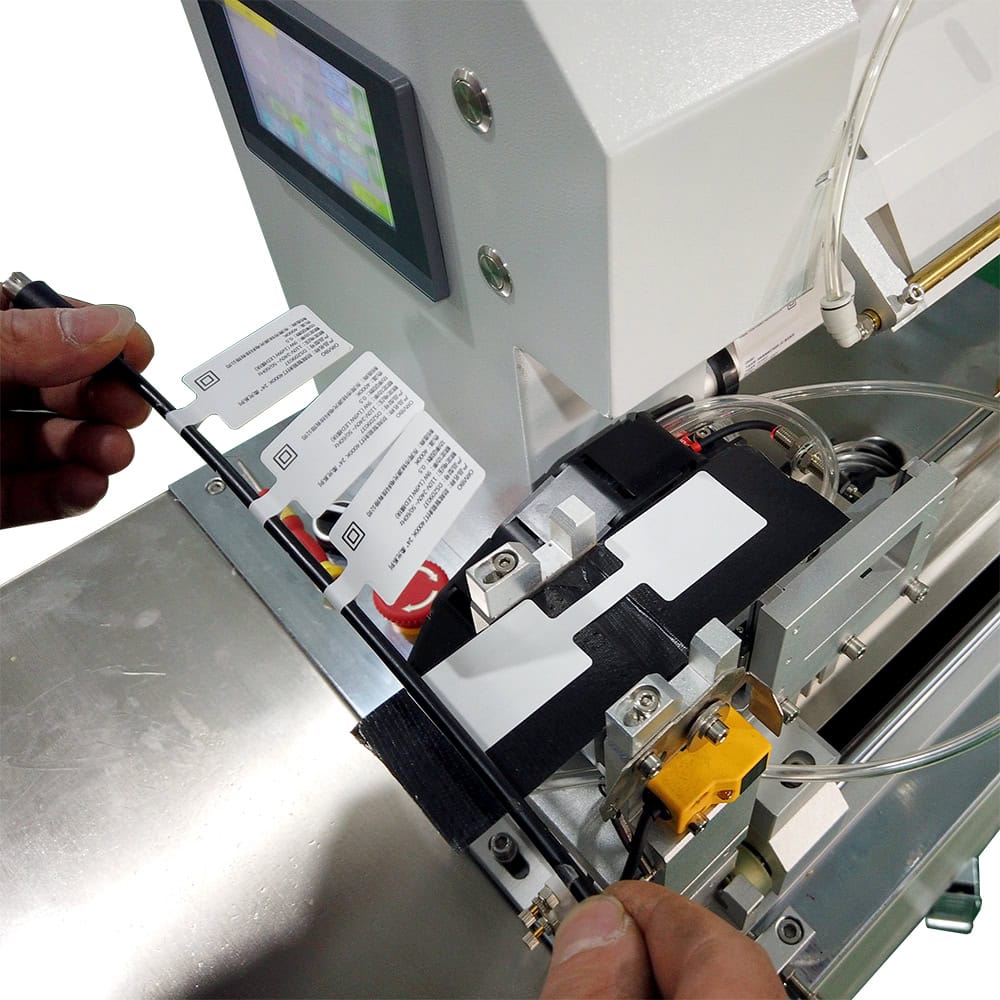

Leveraging Technology and Automation for Lower Operational Costs

While it might seem like a high-tech labeling machine would come with a hefty price tag, the increased efficiency and reduced labor costs can justify the initial investment. For example, an automated machine that reduces the need for manual intervention can save time and reduce the likelihood of human error, which ultimately leads to cost savings.

Investing in a machine with enhanced features, such as advanced industrial shrink wrap or barcode printers, may allow you to streamline your operations, increase throughput, and improve accuracy—all of which contribute to the overall cost-effectiveness of your labeling process.

Conclusion

Securing the lowest price for a wire harness flag labeling machine requires a strategic approach. By clarifying your functional requirements, negotiating effectively, and evaluating suppliers’ reputations and terms, you can secure the best deal. Additionally, considering factors like after-sales support, payment terms, and technological features will help you balance cost and quality for the most cost-effective solution. Remember, the key is to invest wisely, focusing on long-term value rather than just the initial price tag.