If you wrap it up in a crap job, what happens? Well, your stuff can get jacked up and you lose a lot of money. Cheating on how you do your stretch wrapping is not a good plan.

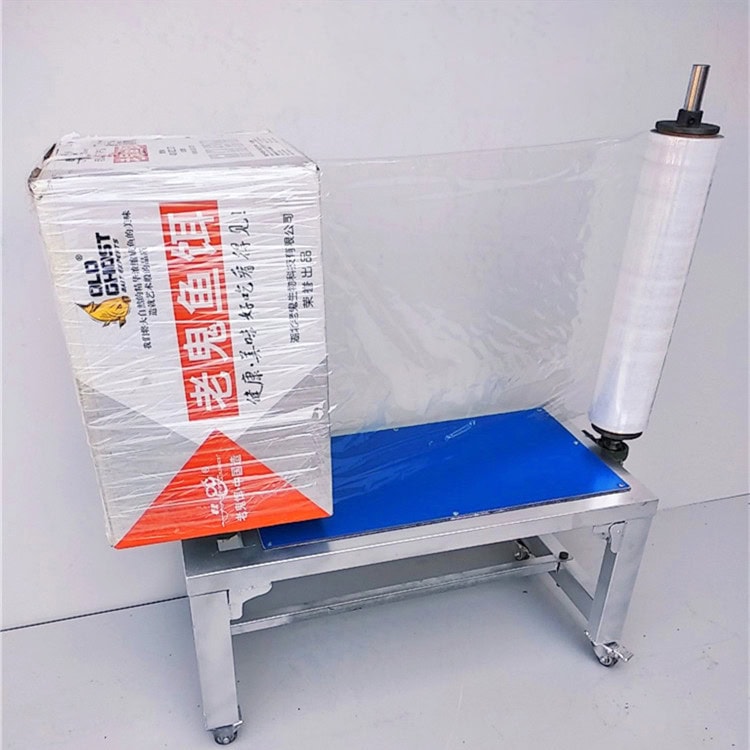

Pallet wrappers improve load stability, reduce film waste, and lower labor costs, making them essential in modern logistics. They enhance safety, ensure consistent wrapping, and contribute to sustainability efforts, all while boosting operational efficiency.

Pallet wrappers offer various benefits that make them indispensable in industries relying on efficient and reliable packaging solutions.

Increased Load Stability

One of the most significant advantages of using a pallet wrapper is the improved load stability it provides. By tightly wrapping the pallet, the products are secured in place, preventing them from shifting during transit.

This not only reduces the likelihood of product damage but also ensures that goods reach their destination in optimal condition. For businesses that rely on safe and efficient transportation, this benefit is crucial in minimizing returns and ensuring customer satisfaction.

Additionally, the stability achieved through pallet wrapping helps reduce accidents during loading and unloading processes. A well-secured load is less likely to collapse or shift, making the workplace safer for warehouse and logistics staff.

Reduction in Film Waste

Pallet wrappers equipped with pre-stretch technology optimize the use of stretch film, resulting in less material waste. This technology stretches the film before applying it to the pallet, allowing for more coverage with less material. Businesses that use pallet wrappers can see a significant reduction in the amount of plastic used, lowering packaging costs and contributing to their sustainability goals.

Reducing film waste is not only cost-effective but also environmentally beneficial. By using less plastic, companies can reduce their carbon footprint, aligning their operations with global sustainability efforts.

Lower Labor Costs

Manual pallet wrapping is labor-intensive, time-consuming, and often inconsistent. Pallet wrappers automate this process, allowing businesses to reduce the need for manual labor. Employees can focus on more critical tasks, increasing overall productivity. With the right pallet wrapping machine, businesses can wrap more pallets in less time, reducing bottlenecks in the packaging process.

This reduction in manual labor also leads to lower operational costs. Investing in a pallet wrapper can quickly offset the initial expense by minimizing the need for extra workers to handle the wrapping process.

Improved Safety

Manual pallet wrapping can expose workers to repetitive strain injuries and other physical risks. Automating this process with a pallet wrapper significantly enhances workplace safety by reducing the need for workers to manually handle heavy pallets and stretch film. By eliminating the physical strain associated with wrapping, businesses can reduce workplace injuries and ensure a healthier workforce.

Moreover, consistent wrapping provided by machines ensures that the load is stable, reducing the risk of accidents during transport, which is another critical safety benefit of pallet wrappers.

Faster Wrapping Speeds

Pallet wrappers offer much faster wrapping speeds compared to manual methods. Machines can wrap pallets in a fraction of the time it takes for a person to do the same job. This speed translates into higher throughput, enabling companies to process more shipments in a day, ultimately boosting efficiency in the warehouse.

With faster wrapping times, businesses can also meet tighter shipping deadlines and reduce delays in their logistics operations. The ability to wrap more pallets in less time contributes to overall operational efficiency.

Consistent Wrapping Quality

One of the major drawbacks of manual wrapping is the inconsistency in the application of stretch film. Pallet wrappers ensure a consistent level of tension and coverage for every pallet, providing uniform wrapping quality. This consistency is crucial for maintaining load stability and preventing product damage during transit.

The uniformity provided by a machine is especially important for businesses handling fragile or high-value goods. Consistent wrapping ensures that every pallet is adequately secured, reducing the risk of damage.

Cost-Effective Shipping

By improving load stability and reducing damage, pallet wrappers lead to more cost-effective shipping. Goods are less likely to be damaged in transit, which minimizes returns and reduces the costs associated with replacing or repairing damaged products. This benefit is especially important for businesses that frequently ship long distances or deal with delicate products.

The savings on shipping costs, combined with the reduction in film waste and labor costs, make pallet wrappers a wise investment for businesses looking to improve their bottom line.

Environmental Benefits

Using less stretch film not only lowers costs but also benefits the environment. As sustainability becomes a growing concern, companies are looking for ways to reduce their environmental impact. Pallet wrappers help achieve this by reducing the amount of plastic waste generated. With pre-stretch technology, less film is required to wrap each pallet, helping businesses meet their sustainability goals while also saving money.

This reduction in plastic use is a key advantage for businesses looking to adopt more eco-friendly practices in their packaging operations.

Adaptability to Various Load Sizes

Pallet wrappers are highly adaptable and can be adjusted to accommodate various load sizes and shapes. Whether wrapping large industrial goods or smaller, more delicate items, pallet wrappers can be customized to meet specific packaging needs. This adaptability ensures that businesses can handle a wide range of products efficiently.

Machines like the Flat Labeling Machine and Bottle Labeling Machine also provide similar flexibility, allowing businesses to handle different packaging needs across their product lines.

Reduction in Worker Fatigue

Manual pallet wrapping is physically demanding, often leading to worker fatigue. Automating this task with a pallet wrapper reduces the physical strain on employees, allowing them to focus on less repetitive tasks. This shift not only improves productivity but also enhances worker morale by minimizing the risk of fatigue-related injuries.

Reduced fatigue leads to fewer errors in packaging, contributing to the overall efficiency of the operation.

Enhanced Product Protection

Pallet wrappers protect goods from external elements such as dust, moisture, and contaminants. By tightly wrapping the products, the machine ensures that the goods are sealed and safeguarded against environmental factors that could compromise their quality. This is particularly important for industries dealing with food, pharmaceuticals, or other sensitive products.

For companies using machines like the Shrink Wrap Machine, pallet wrappers provide an additional layer of protection, ensuring that goods remain in perfect condition throughout the supply chain.

Conclusion

Pallet wrappers offer numerous benefits, including improved load stability, reduced costs, enhanced safety, and environmental advantages. These machines are essential tools for any business looking to optimize its packaging process and ensure efficient, reliable operations.

You may be interested in: