Labeling is a critical step in the packaging process across various industries, especially when it comes to bags. The wrong choice of a label applicator machine can lead to poorly adhered labels, damaged bags, or production delays, all of which can have significant impacts on your business.

To ensure your labels stick securely and your production line runs smoothly, choosing the right label applicator machine for bags is crucial. This guide will help you understand the unique challenges of bag labeling and how to select the best equipment for your needs.

Whether you are dealing with plastic, paper, or woven bags, this article will provide insights into overcoming the specific challenges posed by bag labeling, ensuring you make an informed decision that boosts efficiency and product quality.

Why Bag Labeling is Different from Bottle Labeling

Bag labeling differs significantly from bottle labeling due to the inherent structural and material differences between bags and bottles. Unlike the rigid, uniform shapes of bottles, bags can vary greatly in their flexibility, thickness, and surface texture. These differences present unique challenges in the labeling process.

For example, while a label applicator machine for bottles is designed to handle the curved surfaces of round or square bottles, a machine for bags must be able to accommodate the flexible and often uneven surfaces of bags. The material of the bags, such as plastic, paper, or woven fabrics, also affects how well the label adheres and stays in place over time. Inadequate pressure or misalignment can easily cause labels to peel off or crease, reducing their effectiveness and potentially damaging your brand’s image.

Because of these differences, it’s essential to choose a label applicator machine that is specifically designed for bags. This type of machine needs to apply just the right amount of pressure to ensure the label adheres firmly without damaging the bag or compromising its contents.

Key Factors to Consider When Choosing a Label Applicator Machine for Bags

When selecting a label applicator machine for bags, several critical factors must be considered to ensure the machine meets the specific demands of your production environment and the types of bags you are using.

Bag Material and Thickness

The material and thickness of the bags you plan to label are fundamental factors in choosing the right machine. Different materials, such as plastic, paper, or woven fabrics, require different levels of adhesive and pressure to ensure the label sticks securely. For example, plastic bags may need a machine with adjustable heat settings to ensure the adhesive bonds properly, while paper bags might require less pressure to avoid tearing.

Label Position and Type

Another important consideration is where on the bag the label needs to be applied. Some products require labels on the front or back of the bag, while others might need labels on the sides or even across the seal. The type of label—whether it’s a pressure-sensitive label, a thermal transfer label, or another type—also impacts the choice of machine. Your label applicator machine must be versatile enough to handle the specific positioning and type of label required by your product.

Production Environment and Speed

The conditions in your production environment, such as temperature and humidity, can affect the performance of your label applicator machine. Additionally, the speed at which you need to label bags is a key consideration. High-speed production lines require machines that can apply labels quickly and accurately, without sacrificing quality. The ability to adjust the machine’s speed and pressure settings to match your production needs is essential for maintaining efficiency and avoiding bottlenecks.

Specialized Label Applicator Machines for Different Bag Types

Given the diverse nature of bags, it’s often necessary to choose a specialized label applicator machine that is tailored to the specific type of bag you are labeling.

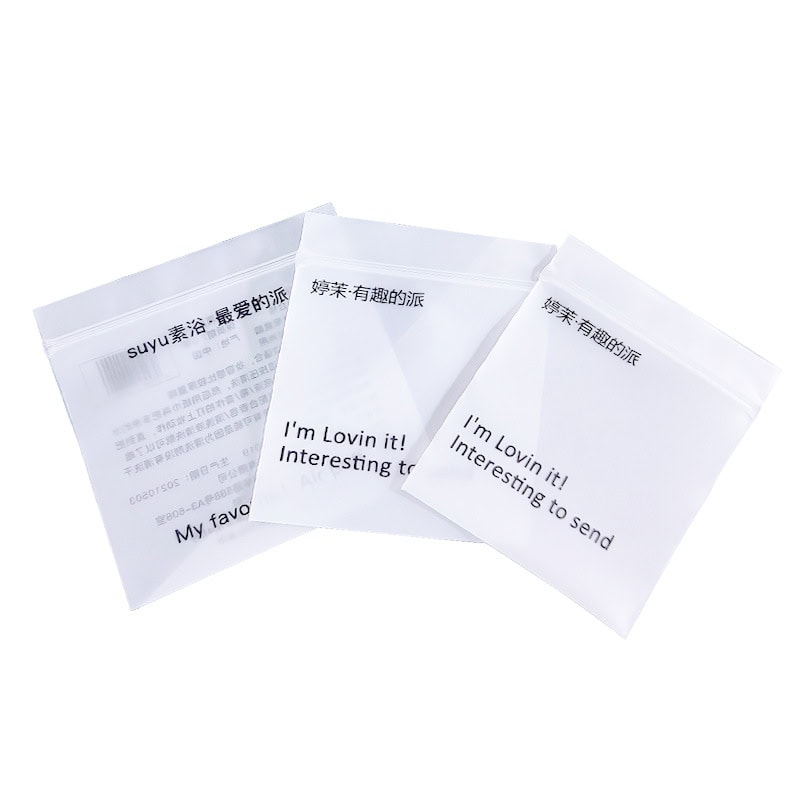

Flat Bag Label Applicator

Flat bags, such as those used for food products or small parts, present unique challenges because the labels need to be applied smoothly and without wrinkles. A flat bag label applicator is designed to ensure that labels adhere evenly across the entire surface of the bag, regardless of slight variations in the bag’s shape or size.

Woven Bag Label Applicator

Woven bags, commonly used for heavier products like fertilizer or grain, require a different approach. These bags are typically thicker and have a more textured surface, making it more difficult for labels to stick properly. A woven bag label applicator uses higher pressure and specialized adhesives to ensure that labels remain secure, even under the stresses of transportation and handling.

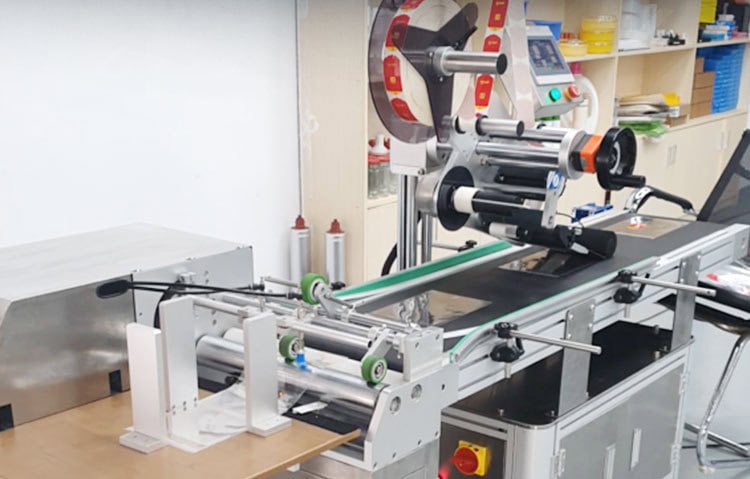

Automated Bag Labeling Solutions

For companies with high-volume production needs, automated bag labeling machines offer significant advantages. These machines can handle large quantities of bags with consistent accuracy, reducing the need for manual intervention and increasing overall efficiency. Automated systems also offer the flexibility to handle different types of bags and labels, making them ideal for businesses that produce a wide range of products.

Real-World Applications and Success Stories

To better understand the impact of choosing the right label applicator machine, let’s look at a few success stories from various industries.

Electronics Packaging Case Study

An electronics company struggled with labels peeling off plastic bags used for packaging small parts. After switching to a label applicator machine designed specifically for plastic bags, they saw a significant improvement in label adhesion, reducing customer complaints and returns.

Fertilizer Industry Case Study

A fertilizer manufacturer using woven bags needed a solution that could withstand the rigors of transportation. By implementing a woven bag label applicator with enhanced adhesive capabilities, they ensured that their labels remained intact from the factory to the final destination, improving product traceability and brand visibility.

Food Industry Case Study

In the food industry, a company faced challenges with labeling paper bags used for dry goods. They opted for a flat bag label applicator that applied labels smoothly without damaging the delicate paper surface, resulting in a more professional appearance and increased consumer confidence in their product.

Tips for Optimizing Bag Labeling Machines

Once you’ve selected the appropriate label applicator machine for bags, maintaining its optimal performance is crucial for ensuring long-term success.

Maintenance and Care

Regular maintenance is key to keeping your labeling machine in top condition. This includes cleaning the machine, checking for wear and tear on moving parts, and making sure that the pressure and speed settings are properly calibrated for the type of bags you’re labeling. A well-maintained machine not only lasts longer but also performs more consistently.

Common Issues and Solutions

Some common issues with bag labeling include labels not sticking properly, misalignment, or tearing of the bag material. These problems can often be resolved by adjusting the machine’s settings or using a different type of label adhesive. Training your operators to recognize and troubleshoot these issues can help keep your production line running smoothly.

Production Line Optimization

To get the most out of your bag labeling machine, consider optimizing your production line setup. This might involve adjusting the flow of bags through the machine to reduce bottlenecks or integrating the labeling machine with other automated systems for seamless operation. Regularly reviewing and refining your production processes can lead to significant improvements in efficiency and product quality.

Conclusion

Labeling bags presents unique challenges that require specialized equipment. By carefully considering factors such as bag material, label type, and production environment, you can select a label applicator machine that meets your specific needs and enhances your production efficiency. Whether you’re dealing with flat bags, woven bags, or a variety of bag types, the right machine can make all the difference.