Cable management can be a daunting task, especially when dealing with a large number of wires and cables in various environments. Mislabeling or unlabeled cables can lead to confusion and inefficiencies, causing delays and increased costs.

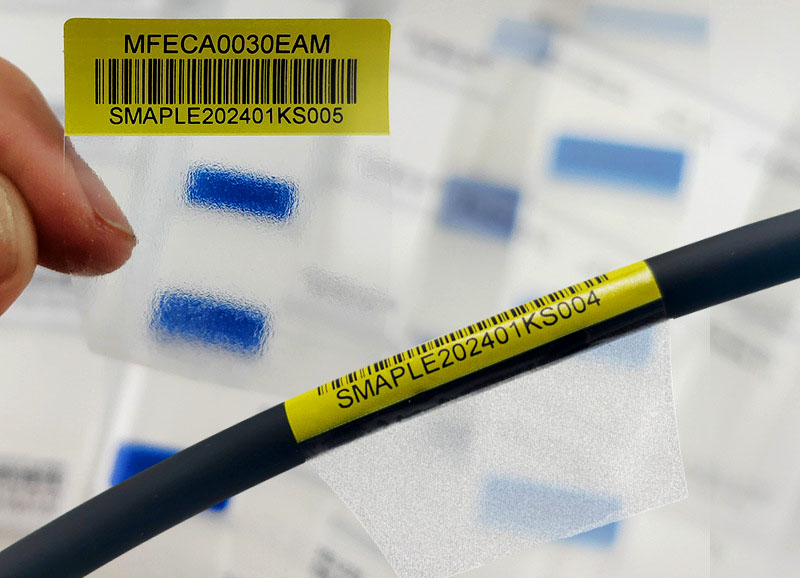

Self-laminating cable labels provide a durable and reliable solution for organizing and identifying cables. These labels are designed to wrap around cables and provide clear, long-lasting identification. They are essential for maintaining an orderly and efficient workspace.

Effective cable labeling ensures quick identification and reduces downtime. With self-laminating cable labels, you can achieve this with ease and precision.

What is a Self-Laminating Cable Label?

A self-laminating cable label is a type of label specifically designed for identifying cables and wires. It consists of a printable area where you can write or print the necessary information. This area is then covered by a clear, protective laminate that wraps around the cable. The laminate protects the printed information from wear and tear, ensuring the label remains legible over time. Self-laminating labels are commonly used in various industries, including telecommunications, electrical installations, and data centers.

Self-laminating cable labels come in different sizes and formats to accommodate various cable diameters and lengths. They are typically made of durable materials that can withstand harsh environments, including exposure to moisture, chemicals, and UV light. This makes them suitable for both indoor and outdoor applications.

What are the Advantages of Self-Laminating Cable Tags?

Self-laminating cable tags offer several advantages over traditional labeling methods. Firstly, the protective laminate ensures that the printed information remains legible and intact, even in challenging environments. This durability reduces the need for frequent label replacements, saving time and resources.

Additionally, these labels provide a professional appearance, enhancing the overall organization and aesthetics of your cable management system. They are also easy to apply, reducing the time required for installation. The clear laminate also protects the printed information from smudging or fading, ensuring long-term readability.

What Material is Used to Produce It?

Self-laminating cable labels are typically made from a combination of durable materials. The printable portion is usually made of a flexible, high-quality polyester or vinyl, which provides a smooth surface for printing. The protective laminate is made from a clear, strong adhesive film that wraps around the cable, shielding the printed information from damage.

These materials are chosen for their resistance to environmental factors such as moisture, chemicals, and UV light. This ensures that the labels remain effective and readable in various conditions, making them suitable for use in a wide range of applications.

What Size Structure Does It Have?

Self-laminating cable labels come in various sizes to accommodate different cable diameters and lengths. The size structure typically includes a printable area and an attached laminate portion. The printable area varies in size, allowing for different amounts of information to be included on the label.

The laminate portion is designed to wrap around the cable, overlapping the printed area to provide complete protection. This structure ensures that the label stays securely attached to the cable while protecting the printed information from external elements.

How to Quickly Stick the Self-Laminating Cable Label on the Cable?

Applying self-laminating cable labels is a straightforward process. Start by printing or writing the necessary information on the label’s printable area. Once the information is in place, peel off the backing to expose the adhesive side of the label.

Place the label on the cable, ensuring that the printable area is aligned correctly. Wrap the clear laminate portion around the cable, covering the printed information completely. Press down firmly to ensure that the laminate adheres to the cable, providing a secure and durable label. For larger projects, consider using a wrap-around labeler to automate the process and improve efficiency.

Self-Laminating Cable Label Applications

Data Centers

In data centers, self-laminating cable labels are essential for organizing network cables. Clear identification of cables reduces downtime during maintenance and upgrades, preventing costly mistakes and streamlining cable management.

Telecommunications Rooms

In telecommunications rooms, these labels help keep track of numerous cables, ensuring that each connection is easily identifiable. This is crucial for troubleshooting and maintaining optimal performance.

Electrical and Power Applications

For electrical and power applications, self-laminating cable labels provide a durable solution for marking wires and cables. They can withstand exposure to moisture, chemicals, and UV light, making them suitable for both indoor and outdoor use.

Audio-Visual Systems

In audio visual systems, clear cable labeling is essential to ensure proper connections, prevent signal loss and maintain system integrity. Self-laminating labels provide a professional and reliable way to organize these cables, which we can also call audio cable labels.

System Integration

System integrators benefit from using self-laminating labels to manage complex wiring systems. These labels help maintain order and clarity, facilitating easier installation and future modifications.

Construction Sites

On construction sites, cables are often exposed to harsh conditions. Self-laminating labels provide a durable and weather-resistant solution for identifying and managing these cables, ensuring safety and efficiency on the job site.

Security Systems

In security systems, proper cable labeling is vital for maintaining system functionality and ensuring quick identification during maintenance or troubleshooting. Self-laminating labels offer a secure and long-lasting method for marking security system cables.

By incorporating self-laminating cable labels in these various applications, you can ensure a more organized, efficient, and professional approach to cable management across different industries.

Self-Laminating Labels for Cables

These labels are essential for various industries, providing a reliable way to identify and organize cables. They come in different sizes and materials to suit different needs, making them a versatile choice for cable management.

Self-Laminating Label Printer

A self-laminating label printer is a specialized device designed to print self-laminating labels. It allows for quick and efficient production of labels, ensuring that you always have the necessary labels on hand for your projects.

Self-Laminating Wrap Around Cable Labels

These labels are designed to wrap around cables, providing a secure and durable method for labeling. They are ideal for use in environments where cables are frequently handled or moved, ensuring that the labels remain intact and legible.

Conclusion

Self-laminating cable labels are a valuable tool for efficient cable management. Their durability, ease of use, and professional appearance make them an essential component of any organized workspace. Investing in these labels will enhance your cable management system and improve overall efficiency.