Yes, it can be cheaper to print your own labels for small-scale or custom orders, especially if you already have a printer and you need different types of labels. If you have high-volume, standard labels, then you might want to outsource to a label factory.

Printing your own labels gives you flexibility. You can change the labels instantly. This makes it great for people selling stuff on eBay and small businesses that have different customer information. However, as you get more and more orders, the time and effort it takes to print the labels might not be worth the money you save.

When Do You Print Your Own Labels?

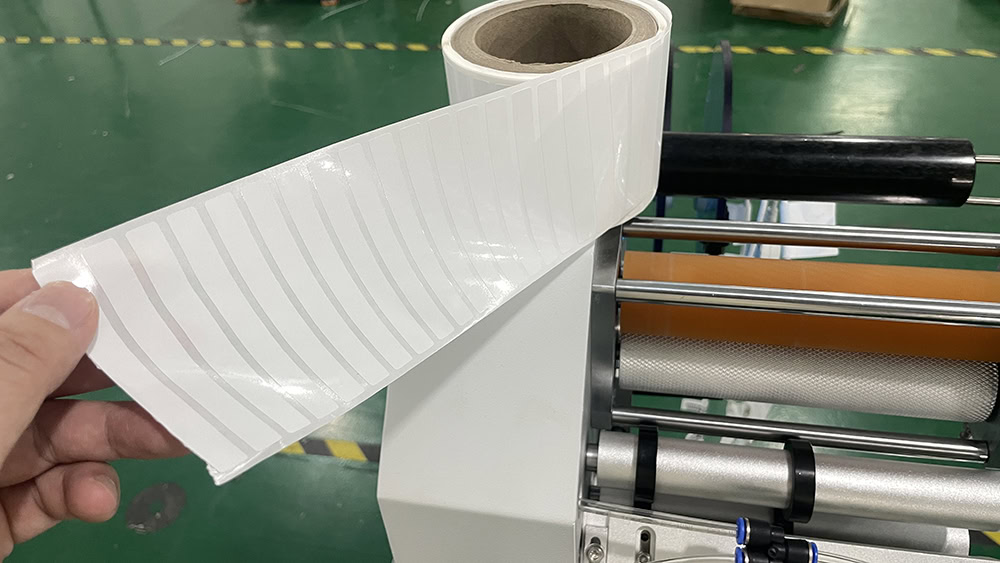

If you have a printer, printing your own labels will likely be the cheapest way to go. In the case of small businesses, like individual sellers on eBay or people who sell across borders, you have to print labels because each customer has different shipping information. You can buy a thermal printer and blank label rolls. When you need to print a label, you can do it.

For larger operations, it might not be the case. You might be able to get labels cheaper if you have them made in bulk from a label factory.

Do You Have Time to Print Your Own Labels?

As your business grows, you need to ask yourself whether you have time to print labels. Printing labels can take a lot of time, especially when you have a lot of orders.

If you have a small business and each customer has different information, it makes sense to print labels in-house. However, if you get busy, you might need to hire somebody to print labels so you can spend your time doing other things.

How Do You Print Your Own Labels?

When you start printing labels, you need to know how to use your printing equipment and setup. You have to know how to install the printer, load label rolls, and connect it to your information system so you can print the labels. You also need to know how to make different types of templates for the different types of labels.

The good news is most of this stuff comes with a detailed manual and troubleshooting guide. Also, places like Amazon or Shopify have resources to show you how to set up and make labels that are the right size to print on your printer.

Where to Purchase Blank Labels?

When you decide to print labels, the next thing you need to do is buy blank labels. You have to think about things like the size of the labels and the material they’re made from. Most of the e-commerce platforms will tell you what size and what type of material the labels need to be. For example, thermal printers use thermal label paper to print on.

There are a bunch of different online suppliers where you can buy blank labels. They have all different kinds of sizes. You can compare prices and pick the ones that fit your needs. If you need a lot of labels, you might want to look for a source that can ship to you from China. They have a lot more selection, and the prices are often better.

When to Find a Label Factory to Make Labels?

Printing in-house makes sense for small businesses and custom orders. It doesn’t make sense for a big operation like a beverage factory. They have labels that are mass-produced and the same. They have the same branding, the same information and the same expiration date. It’s easier for them to outsource it to a label factory.

At the industrial level, the labels are high quality. They have beautiful graphics on them and are made from really good material. They’re able to stand up to different conditions like moisture and heat. If you have food and beverage products, you need your label to be able to get wet and not fall apart. You need your label to be able to get hot and not fall apart.

How to Find the Right Label Factory?

If you run a big operation and you need to buy labels, you need to find a label factory. A good place to start is asking your equipment supplier if they have any recommendations for label factories. A lot of times, machine manufacturers have partnerships with label suppliers. It’s a one-stop-shop for both the machine and the labels.

On the other hand, companies like LabeMachine make labeling machines and have their own label production division. That way, you can buy the machine and the labels from the same people.

How Many Labels Are You Going to Make?

The quantity of labels you need is going to determine whether you should print labels in-house or order them from a factory. If you only need a few labels, it might make sense to print them yourself. However, a lot of times, a label factory will have a minimum order. You have to order a bunch of labels to make it worth their time.

You also have to think about things like the scale of your production and how much waste you have. When you get your machine, you’re going to have to fine-tune it. When you do that, you’re going to waste some labels. You need to order a few more labels than you think you’re going to need, maybe 10% extra, to cover that waste.

Do You Know How to Communicate with Label Factories?

When working with label factories, knowing how to ask the right questions is critical to getting the best results. Important questions to ask include:

- Are you the manufacturer or a middleman?

- What is your range of label sizes and materials?

- What is your minimum order quantity?

- Can you assist with label design?

- What is the production time?

- If I order in larger quantities later, will I receive a discount?

Comparing different factories is a good idea, especially in competitive markets like China. Factories that work with the people who make the labeling machines might also give you a better deal.

How to Determine the Size of Your Labels?

The size of your labels depends on a few things. First, it depends on the size of your product. Second, it depends on how much stuff you need to put on the label. Your label needs to fit the surface of your product. It needs to go on there and be smooth, so it can’t be all wrinkled up.

You also need to make sure your labels are the right size for your labeling machine. If you have the wrong size label, it can cause all kinds of problems with your machine. Some places like Amazon or the people who sell the labels will give you a template or a recommendation for the size of the product.

How to Determine the Material of Your Labels?

The material your labels are made from depends on the environment they will be in. For example, if you have a food or beverage product, your label might need to be waterproof and heat resistant. If you have an electronic item, you might need a label that’s scratch resistant:

- Copperplate Paper: Suitable for indoor environments and widely used in food packaging.

- PVC: Durable and water-resistant, ideal for outdoor use or harsh conditions.

- PET: Known for its strength and resistance to heat and chemicals.

- Thermal Paper: Frequently used for shipping labels, as it is easy to print with thermal printers.

How Much Does It Cost to Make a Label?

The cost to make a label depends on how many you want, what material you want them made from, and what size you want them. You tell the label factory these details, and they’ll give you a price. To get the best deal, ask the people who make the labeling machine to recommend somebody. A lot of times, they have a connection.

Conclusion

Printing your own labels is a cheap solution if you’re a small business. If you’re a big operation, you might want to use a label factory.