When choosing a wire cable flag label folded labeling machine, you may encounter several options. If the wrong machine is selected, you could face issues such as reduced productivity, increased costs, and frequent maintenance.

To choose the right wire cable flag label folded labeling machine, focus on the machine’s speed, accuracy, compatibility with your label sizes, and overall durability. Make sure the machine fits your production capacity and integrates well with other systems like packaging and filling machines.

Let’s dive deeper into the essential factors to consider when selecting the perfect labeling machine for your business needs.

Understanding Wire Cable Flag Labeling Machines

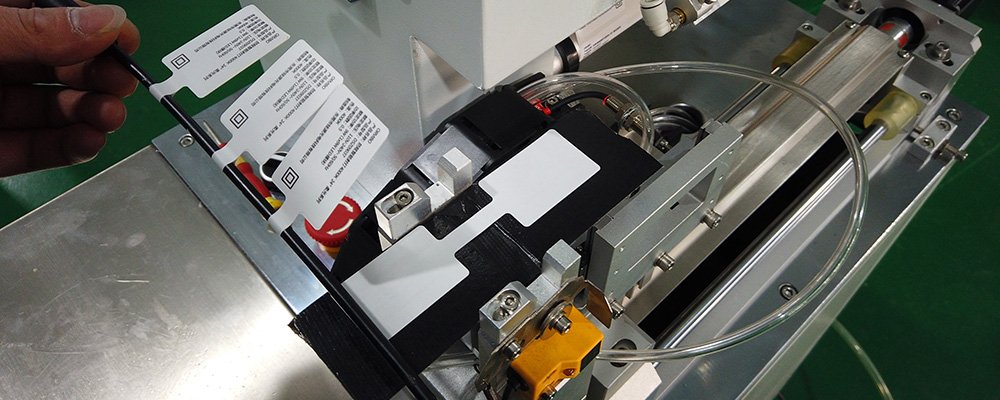

Wire cable flag labeling machines are specialized equipment designed to apply labels on wire cables efficiently. They are used across various industries, including electronics, telecommunications, and manufacturing. These machines are particularly useful for labeling cables with flags—labels that are easy to read and ensure clear identification in complex systems.

Wire cable flag labeling machines are not only essential for organizing inventory but also improve brand recognition by providing clear and professional labeling on cables, wires, and other similar products.

Types of Wire Cable Labeling Machines

When selecting a wire cable flag labeling machine, understanding the different types available is essential. Some of the most common types include:

- Automatic Flag Labeling Machines – These are designed for high-volume production and offer quick and efficient labeling.

- Semi-Automatic Machines – These machines are suitable for medium-sized businesses and offer flexibility with a mix of manual and automatic operation.

- Custom Labeling Machines – These are tailored to meet specific requirements such as unique label designs or special product specifications.

Each type has its advantages, depending on your production needs and budget.

Key Features to Consider in Labeling Machines

The features of a wire cable flag labeling machine can significantly affect its efficiency and performance. Here are a few features to consider:

- Labeling Speed: The machine should be fast enough to keep up with your production line without causing delays. Machines with adjustable speeds allow for more flexibility.

- Accuracy and Precision: Ensure that the machine can apply labels consistently without errors. A machine with higher precision ensures fewer rejections and reduced waste.

- Ease of Use: A user-friendly interface ensures that your staff can operate the machine without extensive training.

These features play a critical role in enhancing productivity and reducing downtime in the long run.

Labeling Speed and Efficiency

One of the most crucial factors when selecting a wire cable flag labeling machine is the speed and efficiency of the machine. If your business relies on high throughput, you need a machine that can apply labels at a rapid pace without compromising accuracy.

High-speed machines are ideal for large-scale operations where quick turnarounds are necessary. However, it’s important to balance speed with labeling accuracy to prevent wasted labels and rework.

Size and Label Compatibility

Before purchasing a wire cable flag labeling machine, ensure that it can accommodate the size of the labels you intend to use. Some machines are designed to work with only specific label sizes, while others are more flexible.

Label compatibility is important for maintaining the aesthetic appeal and functionality of your products. If your business uses a variety of labels or plans to switch label sizes in the future, look for a machine with adjustable settings to handle different label formats.

Automation and User-Friendliness

An automated wire cable flag labeling machine can significantly improve your operational efficiency. These machines reduce human error and minimize the need for manual intervention, resulting in less downtime and lower labor costs.

However, automation does not mean complexity. A user-friendly interface that allows easy adjustments, such as label size or application speed, is important for smooth operation.

Machine Durability and Maintenance

Durability is a key consideration when selecting a labeling machine. A high-quality, durable machine can withstand the rigors of continuous use, making it a cost-effective choice in the long run.

Additionally, ease of maintenance is essential. Machines that require frequent repairs or complex maintenance routines can lead to downtime and production delays. Choose a machine with easily accessible parts and a vendor who offers good after-sales support.

Cost Considerations

Cost is often a deciding factor in machine selection. When choosing a wire cable flag labeling machine, consider not only the initial purchase price but also the long-term operating costs. Machines with lower upfront costs might have higher operating and maintenance costs, so it’s important to assess the total cost of ownership.

Additionally, keep in mind that investing in a higher-quality machine could result in fewer repairs and a longer lifespan, potentially saving you money in the future.

Customization and Flexibility

Many businesses require labeling machines that can be customized to meet specific needs. Whether it’s the ability to print logos, adjust label sizes, or integrate with other systems such as packaging machines or filling machines, flexibility is essential.

Choosing a machine that offers customization options ensures that it can grow with your business and adapt to future needs.

Vendor Reputation and Support

When purchasing a wire cable flag labeling machine, it’s crucial to consider the reputation of the vendor. Opt for vendors with a proven track record of delivering high-quality machines and offering excellent customer service.

Also, inquire about the after-sales support provided. Will they offer technical assistance, spare parts, and regular updates to ensure your machine operates at its best?

Summary

Choosing the right wire cable flag labeling machine requires careful consideration of factors such as speed, label compatibility, machine durability, and vendor support. By evaluating these elements, you can select a machine that meets your business needs while ensuring long-term efficiency and productivity.