When it comes to labeling, especially after a coating process, the stakes are even higher. A coating labeling machine must not only apply labels accurately but also ensure that the labels adhere properly to the coated surface. This guide will help you navigate the complexities of selecting the ideal machine for your specific needs.

Choosing the right coating labeling machine involves understanding your industry’s specific requirements, such as the type of coating, the production speed, and the material being labeled. By assessing these factors, you can ensure optimal performance and avoid costly errors in your production line.

Before making a decision, it’s essential to dive into the key features and types of coating labeling machines, as well as the best practices for maintenance. This comprehensive approach will equip you with the knowledge needed to make an informed choice.

What is a Coating Labeling Machine?

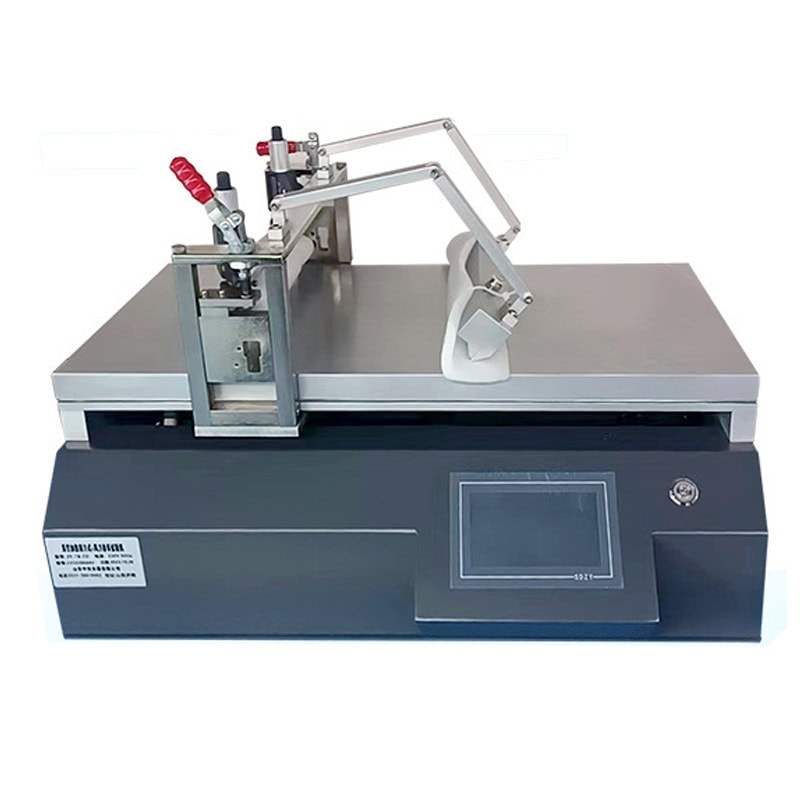

A coating labeling machine is a specialized piece of equipment designed to apply labels to surfaces that have been coated with a protective, decorative, or functional layer. These machines are crucial in industries where products undergo a coating process before labeling, such as in electronics, pharmaceuticals, and food packaging. The machine must handle the delicate balance of applying labels that stick well to coated surfaces without compromising the coating’s integrity.

In industrial applications, coating labeling machines play a pivotal role. They ensure that labels are applied accurately and efficiently, even on surfaces that might be challenging due to the coating’s properties. The combination of coating and labeling technologies allows manufacturers to maintain high standards of product presentation and durability.

The integration of surface labeling equipment with coating processes helps streamline production and ensures that products meet quality standards. This integration is particularly important in sectors where both the coating and the label serve functional purposes, such as providing information or enhancing the product’s appearance.

Key Features to Consider

When selecting a coating labeling machine, several key features must be considered to ensure the equipment meets your operational needs. The most critical aspects include:

- Labeling Precision: The machine should offer high accuracy in label placement, especially on coated surfaces where adherence might be more challenging. Precise placement reduces waste and ensures a professional appearance.

- Speed and Efficiency: Depending on your production scale, the machine’s speed can significantly impact your output. High-speed labeling machines are essential for large-scale operations, whereas smaller businesses might prioritize versatility over speed.

- Adaptability: The ability to handle various types of coatings and labels is crucial. Some machines are designed for specific coatings, such as protective or decorative layers, while others offer more versatility across different materials.

- Automation Level: The degree of automation in the labeling process can vary. Fully automated machines are ideal for high-volume production, while semi-automated or manual machines might be sufficient for smaller runs or specialized applications.

These features collectively influence the machine’s performance and its suitability for your specific industrial application. Evaluating these factors against your production needs will help you identify the most appropriate equipment.

Types of Coating Labeling Machines

There are several types of coating labeling machines available, each suited to different applications:

- Protective Coating Labeling Machines: These machines are specifically designed to apply labels to surfaces that have been coated with a protective layer, such as anti-corrosion or moisture-resistant coatings. They ensure that the label adheres securely without compromising the protective layer.

- Decorative Coating Labeling Machines: These are used in industries where aesthetics are crucial, such as in consumer goods. The machine must be able to apply labels cleanly on surfaces with decorative coatings, ensuring the final product looks polished and professional.

- Multi-function Coating Labeling Machines: These versatile machines can handle a variety of coatings and label types. They are ideal for manufacturers who produce different products on the same production line, requiring the machine to adapt quickly to different labeling needs.

Choosing the right type of machine depends on the specific requirements of your production process. For example, if your products primarily involve protective coatings, a machine designed for that purpose will likely be the best fit.

How to Choose the Right Coating Labeling Machine

When selecting the right coating labeling machine for your needs, consider the following steps:

- Assess Your Production Requirements: Start by understanding the specific needs of your production line. Consider factors like production speed, the type of coating, and the material of the surface to be labeled.

- Evaluate Machine Features: Look for machines that offer the features most important to your operation, such as precision, speed, and adaptability. Ensure the machine can handle the specific coatings you use.

- Consider the Level of Automation: Depending on your production volume and budget, decide whether a fully automated, semi-automated, or manual machine is appropriate. Automation can significantly enhance efficiency, but it may come at a higher cost.

- Budget and Cost-effectiveness: Finally, factor in your budget. While it might be tempting to go for the most advanced machine, it’s crucial to balance cost with the features you need. Sometimes, a mid-range machine that perfectly fits your specific needs is more cost-effective than the most expensive option.

Following these steps will help you choose a coating labeling machine that meets your operational needs while fitting within your budget.

Maintenance and Best Practices

To keep your coating labeling machine running smoothly, regular maintenance is essential. This not only extends the life of the machine but also ensures consistent performance. Here are some best practices:

- Routine Cleaning: Regularly clean the machine to prevent dust, debris, and adhesive buildup, which can affect the machine’s performance.

- Regular Calibration: Ensure that the machine is calibrated correctly to maintain label placement accuracy. Calibration should be done periodically, especially if there are noticeable deviations in label application.

- Timely Replacement of Worn Parts: Monitor the machine for any signs of wear and tear, particularly in parts like rollers and cutters. Replace these parts as needed to avoid unplanned downtime.

- Operator Training: Ensure that operators are well-trained in using the machine. Proper usage minimizes the risk of errors and extends the machine’s operational life.

By following these maintenance practices, you can maximize the efficiency and lifespan of your coating labeling machine, ensuring it continues to meet your production needs over time.

Conclusion

Choosing the right coating labeling machine is a critical decision that can significantly impact your production efficiency and product quality. By understanding the specific requirements of your industry and carefully evaluating machine features, you can select a machine that enhances your operation. Remember to factor in maintenance and best practices to keep your equipment in top condition, ensuring long-term success.