Self-adhesive label printing machines are generally used in conjunction with the labeling machine, if your labeling machine equipment needs to be additionally equipped with a self-adhesive printing machine, then you have come to the right place. As a professional with over 20 years in the automation equipment industry, I understand the intricacies and challenges involved in making this crucial decision.

To choose the best self-adhesive label printing machine for your business, you must understand the technology, assess your specific needs, and consider key features such as speed, precision, and durability. Thorough research and informed decision-making are essential to ensure the machine aligns with your business goals.

Now, let’s delve deeper into the elements that make this decision complex and how to navigate the options available in the market.

Understanding Self Adhesive Label Printing Machines

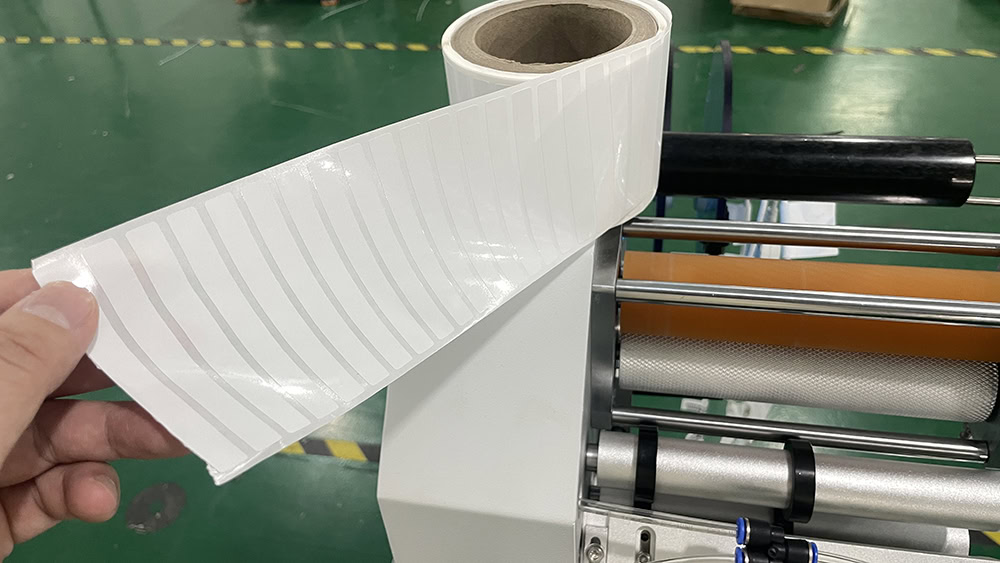

Self-adhesive label printing machines are pivotal in producing labels with a pre-applied adhesive layer. These labels are easy to apply, require no additional adhesives, and can adhere to various surfaces, making them versatile across industries. Understanding these machines’ technology and capabilities is the first step toward making an informed decision.

The mechanics behind these machines involve precision engineering, where every component must work seamlessly to produce high-quality labels. From the unwinding of the label material to the application of graphics and text, each process is automated to ensure consistency and accuracy. This level of automation not only enhances productivity but also minimizes errors, making these machines indispensable for businesses that require reliable labeling solutions.

What Are Self Adhesive Labels and How Do They Work?

Self-adhesive labels are essentially labels with a pressure-sensitive adhesive pre-applied. This adhesive layer is protected by a liner that is removed before application. The adhesive properties activate upon contact with the surface, making the label stick firmly. This process is simple and quick, making it an efficient solution for various labeling needs.

The versatility of self-adhesive labels lies in their adaptability. This adaptability makes them suitable for diverse industries, from food and beverage to pharmaceuticals. Additionally, these labels can be customized in shape, size, and design, allowing businesses to tailor their branding and product information to their specific requirements.

Types of Self Adhesive Label Printing Machines

There are several types of self-adhesive label printing machines, each catering to different business needs. The most common types include flexographic, digital, and offset printing machines. Flexographic machines are known for their speed and ability to handle large volumes, making them ideal for mass production. They use flexible printing plates to transfer ink onto the label material, producing high-quality prints.

Digital printing machines, on the other hand, offer more flexibility in terms of design and customization. They are perfect for short runs and allow for quick changes in design without the need for new plates. Offset printing machines, although less common in label printing, offer exceptional print quality and are suitable for high-end products that require a premium finish. Understanding the strengths and limitations of each type is crucial in selecting the right machine for your business.

Key Features to Look for in a Self Adhesive Label Printing Machine

When choosing a self-adhesive label printing machine, several key features should be considered. One of the most critical aspects is print speed. Depending on your production needs, you may require a machine capable of handling high volumes efficiently. Print resolution is another vital factor, as it determines the clarity and quality of the labels produced. A higher resolution will ensure that text and images are sharp and legible.

Durability and ease of maintenance are also important. A robust machine with a low maintenance requirement will reduce downtime and increase productivity. Additionally, consider the machine’s compatibility with various label materials and the range of label sizes it can accommodate. Versatility in these aspects will allow your business to adapt to changing market demands and product lines.

Comparing Popular Brands and Models

The market for self-adhesive label printing machines is diverse, with numerous brands and models available. Some of the leading brands include Mark Andy, HP Indigo, and Nilpeter. Each brand offers unique features and advantages, catering to different business sizes and industries. Mark Andy, for example, is renowned for its flexographic machines, which offer high-speed production and excellent print quality.

HP Indigo is a leader in digital printing technology, offering machines that provide unmatched versatility and customization options. Nilpeter, on the other hand, is known for its hybrid machines that combine flexographic and digital printing capabilities. When comparing brands and models, consider factors such as machine capabilities, price, and after-sales support. Investing in a reputable brand with a strong support network can significantly impact your business’s operational efficiency.

Cost vs. Quality: How to Find the Right Balance

One of the biggest challenges in choosing a self-adhesive label printing machine is balancing cost and quality. While it’s tempting to opt for a lower-priced machine, it’s essential to consider the long-term implications. A cheaper machine may require more frequent maintenance, have a shorter lifespan, and produce lower-quality labels. This can lead to increased operational costs and damage your brand’s reputation.

On the other hand, investing in a high-quality machine may require a significant upfront investment, but it can offer long-term benefits. High-quality machines often have better durability, produce superior prints, and require less maintenance. They can also handle higher volumes, improving your business’s productivity and profitability. Therefore, it’s crucial to assess your business’s specific needs and budget constraints and find a machine that offers the best value for money.

Maintenance and Support: What to Expect

Proper maintenance and support are vital for the longevity and efficiency of your self-adhesive label printing machine. Regular maintenance, such as cleaning and replacing worn parts, can prevent breakdowns and extend the machine’s lifespan. It’s essential to follow the manufacturer’s maintenance guidelines and schedule routine check-ups to ensure the machine operates optimally.

Additionally, consider the availability of technical support and spare parts when choosing a machine. A reliable manufacturer or supplier should offer comprehensive support, including training, troubleshooting, and quick access to spare parts. This can minimize downtime and ensure your business’s operations run smoothly. Investing in a machine with strong after-sales support can save you time, money, and stress in the long run.

Common Applications of Self Adhesive Label Printing Machines

Self-adhesive label printing machines are used across various industries for different applications. In the food and beverage industry, these machines produce labels that convey critical information such as ingredients, nutritional values, and expiration dates. These labels must be durable, resistant to moisture and temperature changes, and comply with industry regulations.

In the pharmaceutical industry, self-adhesive labels are used for packaging medications and medical devices. These labels often include barcodes, batch numbers, and usage instructions, ensuring product traceability and patient safety. The cosmetics industry also relies heavily on self-adhesive labels for branding and product information. The versatility and precision of these machines make them suitable for producing high-quality labels that meet the specific needs of each industry.

Industry Case Studies: Success Stories and Best Practices

Several companies have successfully implemented self-adhesive label printing machines to enhance their operations. For example, a mid-sized food packaging company invested in a digital label printing machine, allowing them to produce customized labels for seasonal products quickly. This flexibility enabled them to respond to market trends and increase sales.

Another case study involves a pharmaceutical company that adopted a hybrid label printing machine to improve label quality and compliance. The machine’s advanced features allowed them to produce labels with high-resolution graphics and variable data, ensuring that each label met stringent regulatory requirements. These success stories demonstrate the importance of choosing the right machine and the potential benefits it can bring to your business.

Future Trends in Self Adhesive Label Printing Technology

The self-adhesive label printing industry is continuously evolving, with new technologies and innovations emerging. One of the key trends is the shift towards digital printing, which offers greater flexibility, faster turnaround times, and the ability to produce short runs cost-effectively. Digital printing technology is also advancing, with improved print quality, color accuracy, and the ability to print on various label materials.

Another trend is the increasing demand for eco-friendly label materials and printing processes. As consumers become more environmentally conscious, businesses seek sustainable solutions, such as biodegradable label materials and water-based inks. The development of smart labels, incorporating features such as QR codes and RFID tags, is also gaining traction. These labels can provide additional information and enhance product traceability, offering new opportunities for businesses to engage with customers and streamline operations.

Conclusion

Choosing the right self-adhesive label printing machine is a critical decision that can significantly impact your business’s efficiency and profitability. By understanding the technology, assessing your needs, and considering key features, you can find a machine that meets your requirements and supports your business goals. Stay informed about industry trends and innovations to ensure your labeling operations remain competitive and aligned with market demands. With the right machine and support, you can elevate your brand and meet the evolving needs of your customers.