As a professional in the field of automation equipment, I always take great pains to explain how to select various labeling machine equipment. Because choosing the wrong one directly affects your production schedule and profits.

To select the best label applicator machine for bottles, focus on the bottle’s shape and size, choose the right level of automation, and ensure compatibility with your label type and material, considering your production’s speed and accuracy needs.

This guide will show you exactly how to pick the right one for your specific bottles and needs. Whether you have round bottles, square bottles, or oval bottles, I’m going to help you avoid common mistakes and optimize your labeling process.

Understanding Label Applicator Machines for Bottles

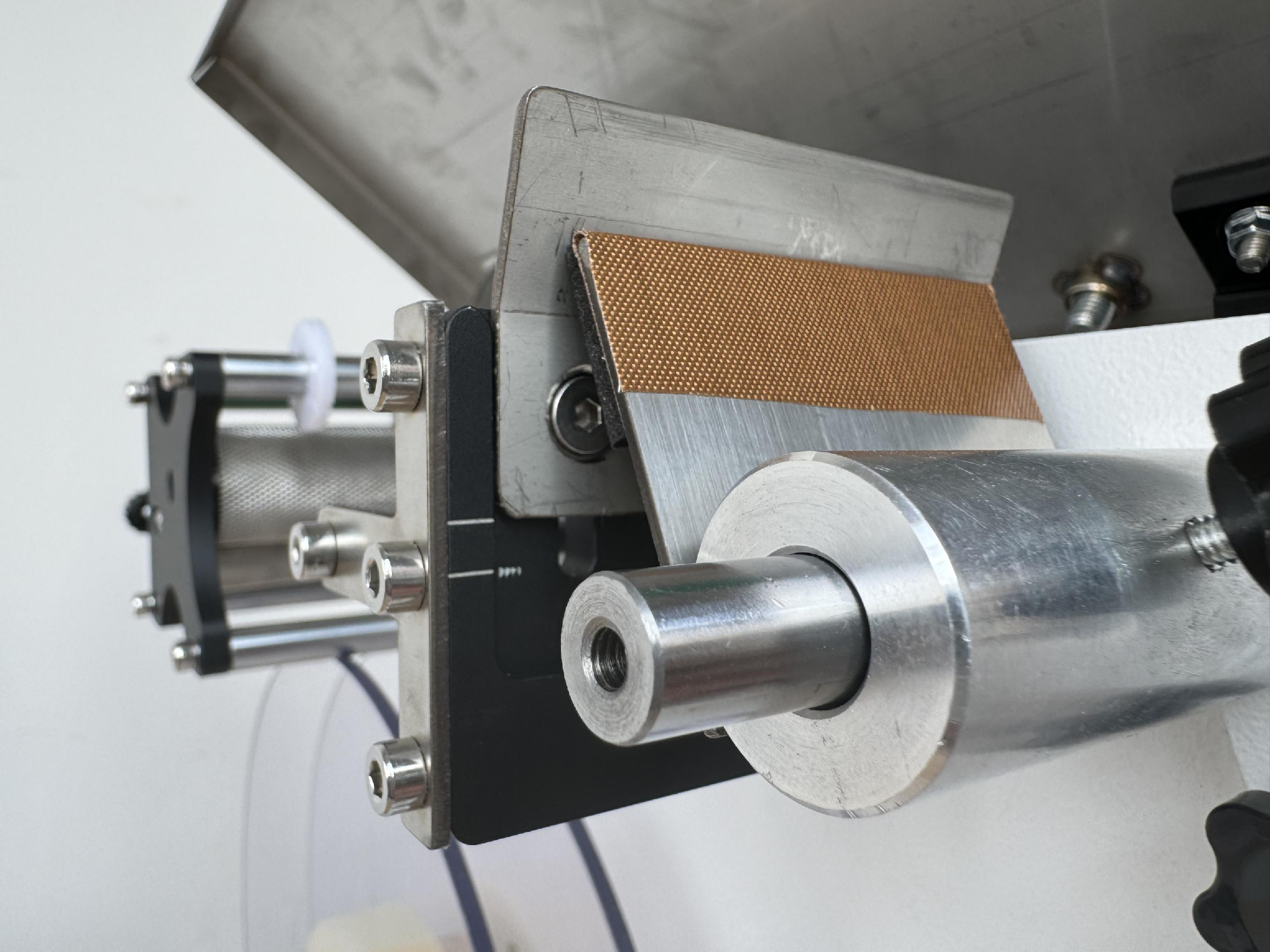

Label applicator machines are specialized devices designed to apply labels to bottles efficiently and accurately. These machines come in various configurations, depending on the shape and size of the bottles they are intended to label. The core components of these machines typically include a label dispenser, a bottle positioning system, and an application mechanism that ensures the label is applied smoothly and securely.

The type of bottle plays a crucial role in determining the kind of label applicator machine needed. For example, round bottles require a machine that can handle the curvature without causing wrinkles or misalignment. On the other hand, square or oval bottles might need more precise handling to ensure the labels are applied flat and centered.

Industries such as food and beverage, cosmetics, and pharmaceuticals often have varying requirements when it comes to labeling. For instance, the cosmetics industry might demand a high level of precision and the ability to apply labels to uniquely shaped containers, while the pharmaceutical industry might prioritize compliance and safety, necessitating machines with high accuracy and reliability.

Key Factors to Consider When Choosing a Label Applicator Machine

When selecting a label applicator machine for bottles, several critical factors must be taken into account to ensure the machine meets your production needs and quality standards.

Bottle Shape and Size

The shape and size of the bottles you intend to label will heavily influence your choice of machine. Round bottles, for example, require a machine that can apply labels evenly around their circumference, while irregularly shaped bottles may need a more specialized setup to ensure the label adheres properly. It’s essential to choose a machine that can accommodate the dimensions and contours of your bottles.

Automation Level

Label applicator machine for bottles range from semi-automatic to fully automatic models. Semi-automatic machines are suitable for smaller operations or where manual oversight is required, offering greater control over the labeling process. In contrast, fully automatic machines are ideal for high-volume production environments, where speed and consistency are paramount. The choice between these options should be based on your production scale and the level of efficiency you aim to achieve.

Label Type and Material

The type of labels you plan to use—whether they are pressure-sensitive, heat-shrink, or other varieties—will also determine the appropriate machine. Additionally, the material of the labels and bottles (e.g., glass, plastic) can affect the adhesion and appearance of the labels. It’s crucial to select a machine that can handle the specific label type and material you plan to work with.

Production Speed and Accuracy

Your production line’s speed and the accuracy required for label placement are other vital considerations. Machines with higher throughput capabilities are necessary for large-scale operations, but it’s equally important that the machine maintains precise label placement to avoid issues such as misalignment or air bubbles. Balancing speed and accuracy is key to maximizing productivity while maintaining quality.

Specialized Bottle Labeling Solutions

Depending on the specific needs of your production line, you might require a specialized label applicator machine. Below are some examples of machines tailored to particular bottle types and industry needs.

Round Bottle Label Applicator

Round bottles are common in various industries, from beverages to personal care products. A round bottle label applicator is designed to apply labels evenly around the bottle’s circumference, ensuring a smooth and professional finish. These machines are equipped with rollers or belts that rotate the bottle as the label is applied, preventing wrinkles and ensuring alignment.

Labeling Machine for Liquid Bottles

Liquid bottles, particularly those used in the cosmetics and beverage industries, often require specific labeling solutions due to their contents and design. Machines designed for these bottles typically include features that accommodate different bottle heights and shapes, ensuring that the label is applied consistently even if the bottle is not perfectly uniform.

Multi-Function Label Applicator Machines

For companies dealing with a variety of bottle shapes and sizes, multi-function label applicator machines offer the flexibility needed to handle different labeling tasks. These machines can be adjusted to apply labels to different bottle types, making them ideal for businesses that produce a diverse range of products. This versatility can be a significant advantage, reducing the need for multiple machines and simplifying the production process.

Case Studies: Successful Implementations

To illustrate the impact of choosing the right label applicator machine, let’s look at a few real-world examples where companies have successfully implemented these machines to enhance their production lines.

Food Industry Case Study

A food production company faced challenges with inconsistent labeling on their round bottles, leading to frequent product rejections. By switching to a specialized round bottle label applicator, they were able to achieve a 95% reduction in labeling errors, significantly improving production efficiency and product presentation.

Cosmetics Industry Case Study

In the cosmetics industry, a company needed to apply labels to both cylindrical and irregularly shaped bottles. They opted for a multi-function label applicator machine, which allowed them to streamline their labeling process and handle different bottle types without requiring multiple machines. The result was a 30% increase in production speed and a consistent, high-quality appearance across all their products.

Pharmaceutical Industry Case Study

A pharmaceutical manufacturer required a high-precision labeling solution to ensure compliance with stringent industry regulations. They implemented an automatic label applicator machine with advanced sensors and feedback systems, enabling them to achieve near-perfect accuracy in label placement, thereby avoiding costly compliance issues.

Tips for Maintaining and Optimizing Bottle Labeling Machines

Once you’ve selected the appropriate label applicator machine, maintaining its optimal performance is crucial. Regular maintenance and proper use can significantly extend the life of your equipment and prevent costly downtime.

Equipment Maintenance

Routine maintenance is vital for keeping your labeling machine in good working condition. This includes cleaning the machine, inspecting moving parts for wear and tear, and ensuring that all components are properly lubricated. Establishing a regular maintenance schedule can help you catch potential issues before they lead to breakdowns.

Troubleshooting Common Issues

Even with the best machines, issues can arise. Common problems such as misaligned labels or machine jams can often be resolved with simple adjustments. Having a trained operator who understands the machine’s functions and troubleshooting protocols can minimize downtime and keep your production line running smoothly.

Optimization Tips

To further enhance the efficiency of your labeling machine, consider optimizing its settings and configuration. This might involve adjusting the speed of the conveyor, fine-tuning the label placement mechanism, or upgrading certain components to improve performance. Regularly reviewing and optimizing your machine’s setup can lead to increased productivity and better labeling outcomes.

Conclusion

Choosing the right label applicator machine for bottles is a critical decision that can significantly impact your production line’s efficiency and the quality of your products. By considering factors such as bottle shape, automation level, label type, and production speed, you can select a machine that meets your specific needs and enhances your overall operations.

For personalized advice and to explore the best options for your business, don’t hesitate to reach out to a professional labeling machine supplier who can provide tailored solutions to fit your unique requirements.