Choosing the wrong pallet wrapping machine can lead to inefficient operations, increased material costs, and even damaged goods. Investing in the right machine ensures smooth packaging, lower costs, and maximum load stability.

To choose a good pallet wrapping machine, assess your load types, packaging frequency, and desired automation level. Key considerations include machine type, film compatibility, and maintenance requirements.

Finding the right pallet wrapping machine means understanding the specific needs of your operation and the capabilities of different machines on the market.

Identify Your Load Type and Requirements

When selecting a pallet wrapping machine, start by identifying the types of loads you’ll be wrapping. Consider the size, shape, and stability of each load. For instance, stable, uniform loads benefit from a simpler machine, while irregular or fragile items may need a more sophisticated system.

Evaluating load type will also help determine the amount of wrap required for secure packaging. Irregular loads may need additional wrap layers or special features that allow for consistent wrapping without causing damage to products. Using a machine like an industrial label printer can complement this process by marking wrapped loads clearly for easier tracking.

Choose the Appropriate Wrapping Technique

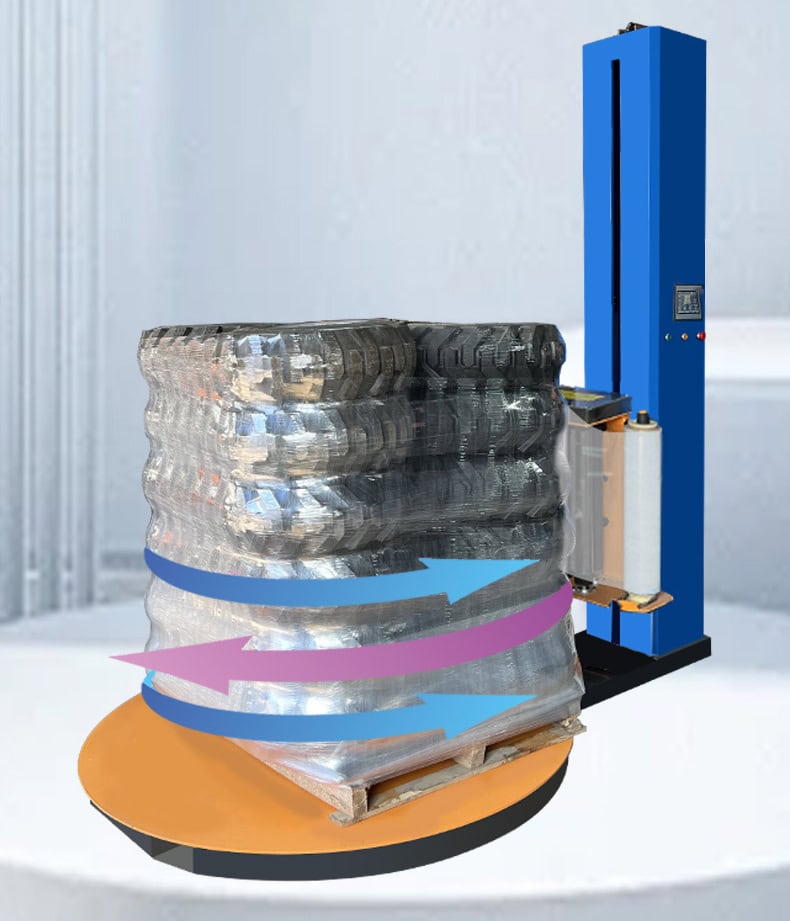

The type of wrapping technique is essential in determining machine effectiveness. Machines primarily offer two main techniques: pre-stretch and non-pre-stretch.

- Pre-stretch Wrapping Machines: These maximize film use and reduce material costs, stretching the wrap before applying it to the pallet. This method suits companies aiming to cut down on material costs.

- Non-Pre-Stretch Machines: These apply film directly to the load without pre-stretching, which can work for low-volume applications or if packaging flexibility isn’t critical.

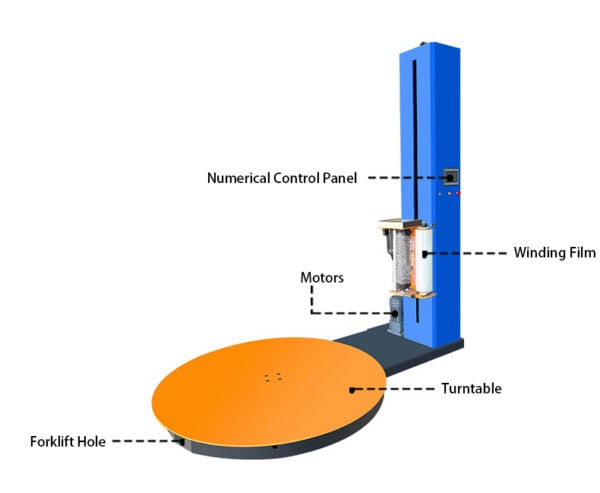

There are also various machine designs, including turntable, rotary arm, and rotary ring wrappers. Turntable models suit lighter, stable loads, while rotary arm and ring machines handle heavier, more unstable pallets.

Consider the Level of Automation

Selecting the right automation level—manual, semi-automatic, or fully automatic—impacts packaging efficiency and speed.

- Manual Wrapping Machines: Ideal for small-scale operations with low output needs, these machines are straightforward but require more operator input.

- Semi-Automatic Machines: Offering a balance of speed and flexibility, these are best for medium-sized operations. Operators may need to start and stop cycles, but wrapping is still automated.

- Fully Automatic Machines: For high-volume settings, fully automatic machines eliminate the need for constant operator involvement, speeding up the packaging process. Many packaging machines can be integrated seamlessly with other automated systems for enhanced productivity.

Evaluate the Machine’s Compatibility with Different Films

Film compatibility is a major consideration. High-quality machines should handle multiple film types, including thin and thicker gauges.

Compatibility features like adjustable film tension settings allow you to customize wrapping based on load types. Machines compatible with a wide range of films are more versatile, reducing the need to purchase multiple types of stretch wrap. Ensuring compatibility across materials also helps avoid wastage and ensures stability across load types.

Analyze Throughput and Speed Requirements

Throughput is crucial when determining the efficiency of a wrapping machine. Consider the number of pallets you need to wrap per hour or day and choose a machine with a wrapping speed that aligns with these requirements.

High-speed machines benefit large operations where thousands of pallets are wrapped daily, while slower models suit small-to-medium-scale businesses. Balancing throughput with speed ensures that your operation keeps pace with demand without excessive costs.

Check for Safety and Ease of Use

Prioritize a machine that meets industry safety standards. Features such as emergency stop buttons, automatic film-cutting systems, and load detection sensors enhance safety and minimize risks for operators. A machine that’s easy to operate will require minimal training and reduce operational errors.

Consider a user-friendly interface that enables operators to set custom parameters quickly. For instance, machines with touch screens or pre-set programs simplify switching between wrap settings. Choosing a machine with a robust safety profile minimizes downtime and protects both workers and products.

Maintenance and Technical Support

Routine maintenance and technical support can affect the overall productivity of your wrapping machine. Look for models with readily available parts and accessible support channels.

Reliable suppliers should offer maintenance plans or easy access to replacement parts. Preventive maintenance, such as regular inspections, also helps extend the lifespan of the machine and keeps it operating smoothly. Machines from suppliers with strong after-sales support help ensure quick repairs, reducing costly downtime.

Consider the Total Cost of Ownership

While initial costs are important, the total cost of ownership (TCO) includes long-term expenses like energy usage, maintenance, and film consumption.

Investing in a high-quality machine might come with a higher upfront cost, but it often yields lower operational costs. For example, shrink wrap machines designed with energy-efficient components can lead to significant savings over time. Analyzing TCO helps in making a cost-effective decision that aligns with the operational budget.

Assess Energy Efficiency

Energy-efficient machines are a smart investment for businesses looking to reduce operational costs. Many machines now come with eco-friendly settings, reducing power consumption during inactive periods or lighter loads.

Some models also feature sensors that only activate the machine when a pallet is in place, further reducing energy use. These features not only save costs but also align with sustainability goals, offering an eco-friendly edge to operations.

Test for Durability and Build Quality

A durable machine withstands the rigors of daily use, particularly in industrial settings where wrapping machines may operate continuously. Opt for models with industrial-grade components and a sturdy build to ensure consistent performance.

Durability is critical in minimizing long-term costs associated with repairs and replacements. Machines with high build quality, especially those designed for heavy-duty environments, provide stable performance and longevity. Investing in durable machines is especially beneficial in high-output sectors like filling machine operations, where load consistency is key.

Conclusion

Selecting the right pallet wrapping machine requires careful evaluation of load requirements, film compatibility, speed, and maintenance needs. This choice ensures efficient, secure wrapping, aligning with operational goals and reducing costs.