Manual labeling can be a real pain! It’s also inconsistent, time-consuming, and ineffective for growing businesses.

Automatic sticker labeling machines are the answer to your problems. They use sensors, conveyors, and applicators to slap labels on at record speeds. That means you don’t have to worry about human error anymore!

Find out how this technology can help you get more done and label more accurately.

Key Components of an Automatic Sticker Labeling Machine

Automatic sticker labeling machines consist of several key components that ensure smooth operation and high accuracy. The primary elements include:

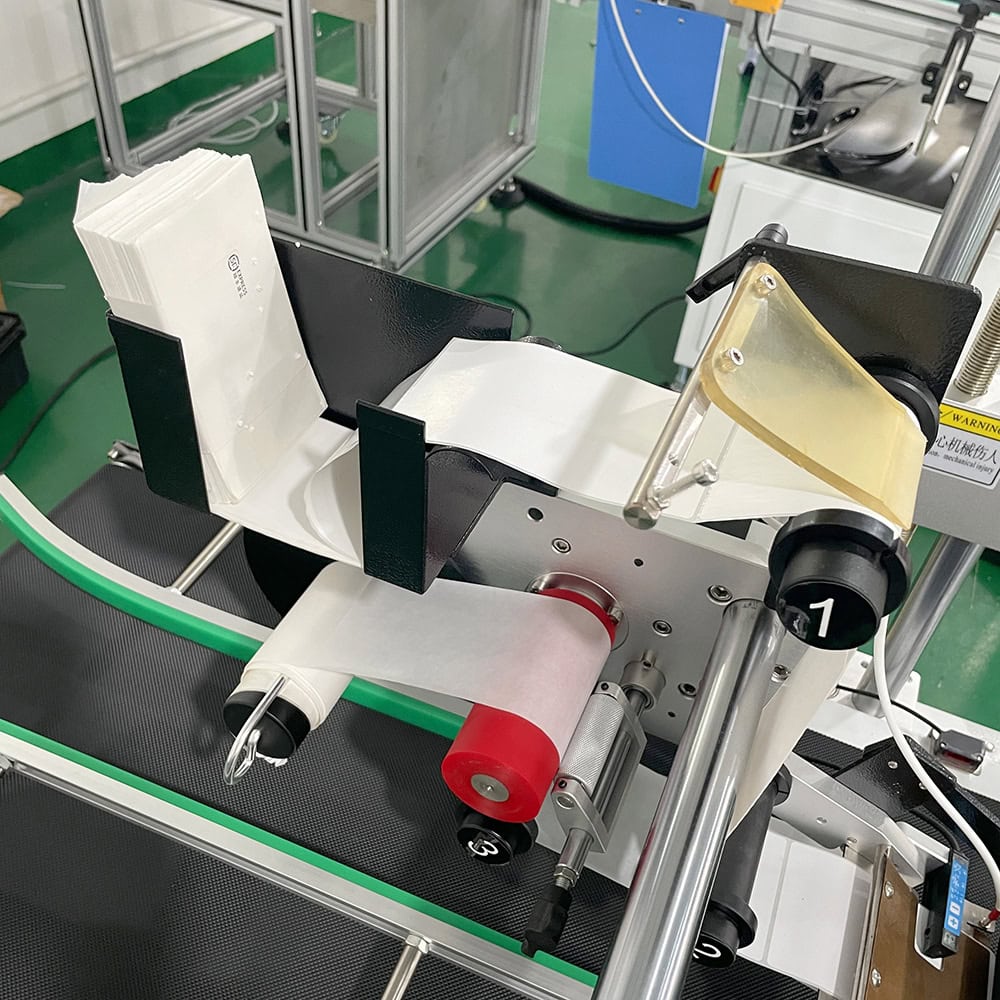

- Conveyor System: This is the core mechanism that moves products through the labeling process. The conveyor ensures that each item is accurately positioned before the label is applied.

- Label Applicator: The applicator is the part that dispenses and adheres the sticker onto the product. It is designed to handle labels of various sizes and shapes and ensure precise placement every time.

- Control Panel: The control panel allows operators to adjust the settings, control the speed, and monitor the labeling process. It is essential for managing different labeling requirements across various product lines.

Working Process of the Machine

The working process of an automatic sticker labeling machine involves several key steps that are executed in a seamless flow:

- Feeding Mechanism: The machine begins by automatically feeding products onto the conveyor. Depending on the type of machine, products are fed either manually or automatically from an upstream production line.

- Label Dispensing: As the product moves along the conveyor, the machine’s sensor detects its position. The label applicator then dispenses the sticker from the backing paper at the precise moment, ready for application.

- Label Application: The label is applied to the product surface through a combination of rollers or air jets, depending on the machine type. This ensures the label sticks smoothly without any air bubbles or wrinkles.

- Inspection and Quality Control: Many modern machines come equipped with an inspection system to check the accuracy of label placement. If a label is misaligned, the system can flag or reject the item, ensuring only perfect labels make it to the packaging stage.

Types of Automatic Sticker Labeling Machines

There are various types of automatic sticker labeling machines, each designed for specific labeling needs:

- Wrap-Around Labeling Machines: These machines apply labels that wrap around cylindrical products like bottles and jars, making them ideal for the beverage and food industries.

- Front and Back Labeling Machines: Designed to apply labels to the front and back of a product simultaneously, this type of machine is perfect for containers with both front and back branding, such as shampoo bottles.

- Top and Bottom Labeling Machines: These machines apply labels to the top and bottom surfaces of flat products, such as boxes, lids, and trays.

Benefits of Using Automatic Sticker Labeling Machines

Investing in an automatic sticker labeling machine brings numerous advantages to a business, including:

- Increased Efficiency: Automatic machines can label hundreds or even thousands of products per hour, significantly boosting production rates compared to manual labeling.

- Consistency and Precision: The accuracy of automatic machines ensures that each label is applied consistently in the correct position, reducing the risk of mislabeling and enhancing product presentation.

- Reduced Labor Costs: With automation, businesses can cut down on manual labor costs, freeing up employees for more value-added tasks and reducing the likelihood of human error in the labeling process.

Industries That Can Benefit from Automatic Sticker Labeling Machines

Several industries rely heavily on automatic sticker labeling machines to meet their high-volume labeling needs:

- Food and Beverage: Labels are crucial for branding and product information in the food and beverage sector. Automatic machines ensure fast and accurate labeling of bottles, cans, and jars.

- Pharmaceuticals: The pharmaceutical industry demands precision and compliance with strict labeling regulations. Automatic labeling machines are ideal for labeling medication bottles, blister packs, and other packaging.

- Cosmetics and Personal Care: In this competitive market, product presentation is vital. Automatic labeling machines ensure that every product has a flawlessly applied label, enhancing its appeal on store shelves.

Maintenance and Care of the Machine

To ensure the long-lasting performance of an automatic sticker labeling machine, proper maintenance and care are essential:

- Regular Cleaning: The machine should be cleaned regularly to prevent dust, adhesive residue, and label debris from interfering with its operation. A clean machine ensures optimal performance.

- Routine Inspection and Troubleshooting: Regular inspections of the machine’s components, such as the rollers, sensors, and applicator, can help detect any potential issues before they lead to downtime. Prompt troubleshooting can prevent major disruptions in production.

Conclusion

Automatic sticker labeling machines streamline the labeling process, improve efficiency, and provide precise, consistent results. With various types available for different applications, these machines are an essential investment for businesses across multiple industries.