Tea companies face high labor costs and inconsistent results when packing tea manually. Errors in filling, sealing, and bagging can compromise quality. A tea bagging machine automates these processes, ensuring precision, efficiency, and consistent quality.

A tea bagging machine automates the processes of measuring, filling, sealing, and packaging tea bags, ensuring consistency, efficiency, and reduced production errors.

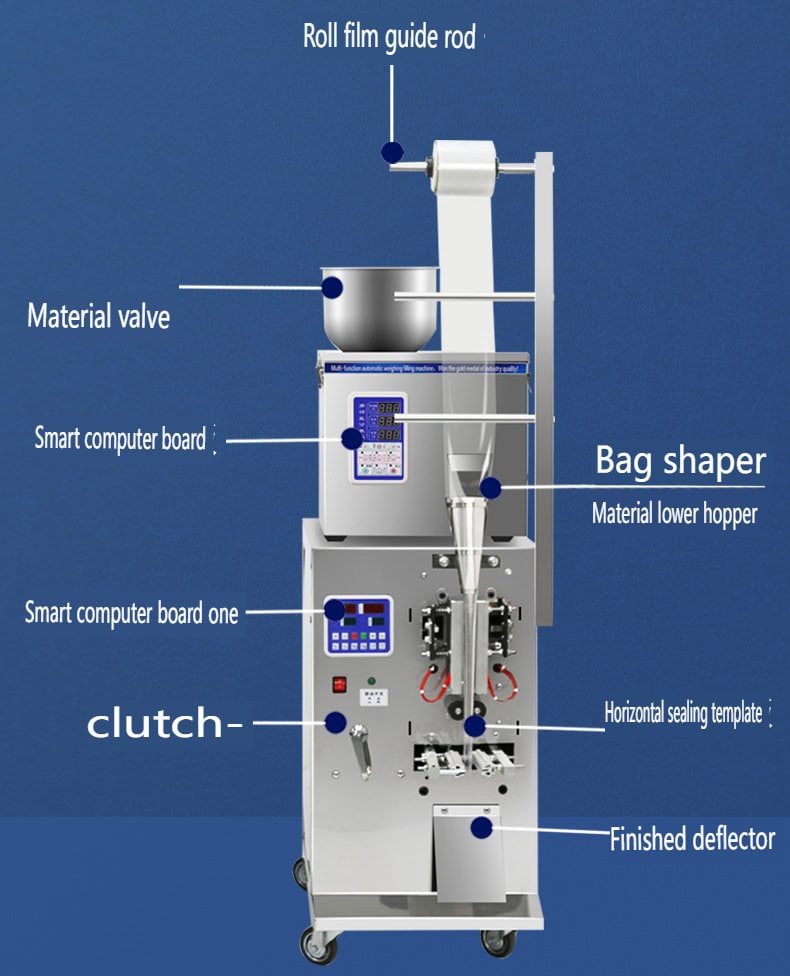

Let’s explore how a tea bagging machine works and the key components involved in the process.

Tea Filling

Tea bagging machines start by accurately measuring the correct amount of tea for each bag. The tea is fed into the machine through a hopper, where it is measured using either a volumetric or weighing system.

- Volumetric System: The machine uses predetermined volumes to dispense a consistent amount of tea into each bag.

- Weighing System: Advanced machines can weigh the tea precisely, ensuring accurate filling for premium tea blends where consistency in weight is crucial.

After the correct amount of tea is measured, it is dispensed into the pre-formed tea bags.

Bag Formation

Tea bagging machines use various materials, including filter paper or mesh, to create the tea bags. The material is typically fed into the machine in rolls and cut to the required size and shape.

- Flat Tea Bags: The machine forms the material into flat, rectangular shapes, a common type found in retail tea products.

- Pyramid Tea Bags: For a premium appearance and enhanced tea infusion, some machines form the material into pyramid shapes, allowing more room for the tea to expand and infuse fully.

Once the material is cut, it moves into the next stage where tea is filled into the bag.

Sealing Process

After the tea is dispensed, the machine seals the bags to secure the contents. Depending on the type of material used, different sealing methods are employed:

- Heat Sealing: In most cases, tea bagging machines use heat to seal the edges of the bag. The material is pressed together and heated, forming a secure seal that holds the tea inside the bag.

- Ultrasonic Sealing: For pyramid-shaped tea bags made from mesh material, ultrasonic sealing is used. This method uses sound waves to bond the edges of the bag without adhesives, creating a reliable seal.

Sealing ensures that the tea remains fresh and the bag remains intact during handling and storage.

String and Tag Attachment

Most tea bags come with a string and tag for convenience. The tea bagging machine automates this process as well:

- String Application: The machine attaches a string to each tea bag, allowing for easy removal from a cup or pot.

- Tagging: A tag is also added to the end of the string, typically displaying the brand or flavor information. The tag is either stapled or sealed to the string, depending on the machine’s setup.

This step adds branding and ease of use for the consumer, while still maintaining the efficiency of the production process.

Cutting and Individual Bag Formation

Once the bags are filled, sealed, and tagged, the machine cuts them into individual tea bags. This cutting process is crucial for clean, neat packaging.

- Precision Cutting: The cutting blade is highly precise, ensuring each bag is separated cleanly from the next. This prevents tearing or damage to the tea bags, which could cause issues during packaging and storage.

- Batch Separation: The machine can group tea bags into batches, preparing them for the next phase of packaging.

Final Packaging

After the tea bags are individually cut and formed, they are often grouped and packaged in cartons or boxes. The tea bagging machine ensures that the bags are counted and sorted properly before moving them into the packaging phase.

- Automated Counting: Sensors on the machine count the number of tea bags as they move along the production line, ensuring accurate packaging counts.

- Carton Packaging: In some machines, an integrated packaging system places the tea bags into cartons or other containers, ready for shipping to retailers.

Automation and Control Systems

Modern tea bagging machines are equipped with advanced control systems, often run by PLC (Programmable Logic Controllers). These systems manage the entire operation from start to finish:

- Precision Controls: Operators can adjust the filling, sealing, and cutting processes according to specific needs. The machine’s controls allow for different tea bag sizes, materials, and sealing methods.

- Sensor Monitoring: Sensors ensure that each step of the process is completed accurately. For example, the machine will not cut or seal a bag unless the tea is properly filled.

This level of automation allows for seamless and error-free operation, even in high-volume production environments.

Types of Tea Bagging Machines

Tea bagging machines vary depending on the type of tea bag being produced and the level of automation required.

- Pyramid Tea Bag Machines: These machines specialize in producing pyramid-shaped bags. Pyramid bags provide better infusion for loose-leaf teas, enhancing flavor extraction.

- Flat Tea Bag Machines: These machines are more common in the industry and produce the standard rectangular tea bags found in most retail environments. They are versatile and can be adjusted for different tea types and sizes.

Each type of machine is designed to maximize production efficiency while maintaining the quality of the tea and the bag.

Conclusion

A tea bagging machine automates the complex processes of filling, sealing, cutting, and packaging tea bags. With precision control systems and advanced features like ultrasonic sealing, these machines ensure consistent quality, improved efficiency, and lower production costs, making them a critical part of modern tea production.

You may be interested in: