A flag machine is a machine you put on the end of a round thing like a long, skinny round thing on an assembly line that you want to put a label around so you can go faster and be more precise which is what we want to do. We only want to do these things if they help us make money and make our lives easier.

A flag machine is a machine that you put on the end of a round thing like a long, skinny round thing on an assembly line that you want to put a label around that can make you go faster and be more precise which is what we want to do. We only want to do these things if they allow us to make money and make our lives easier.

These machines are what you want because they are going to make you go faster and be more accurate.

What is a Flag Label Applicator Machine?

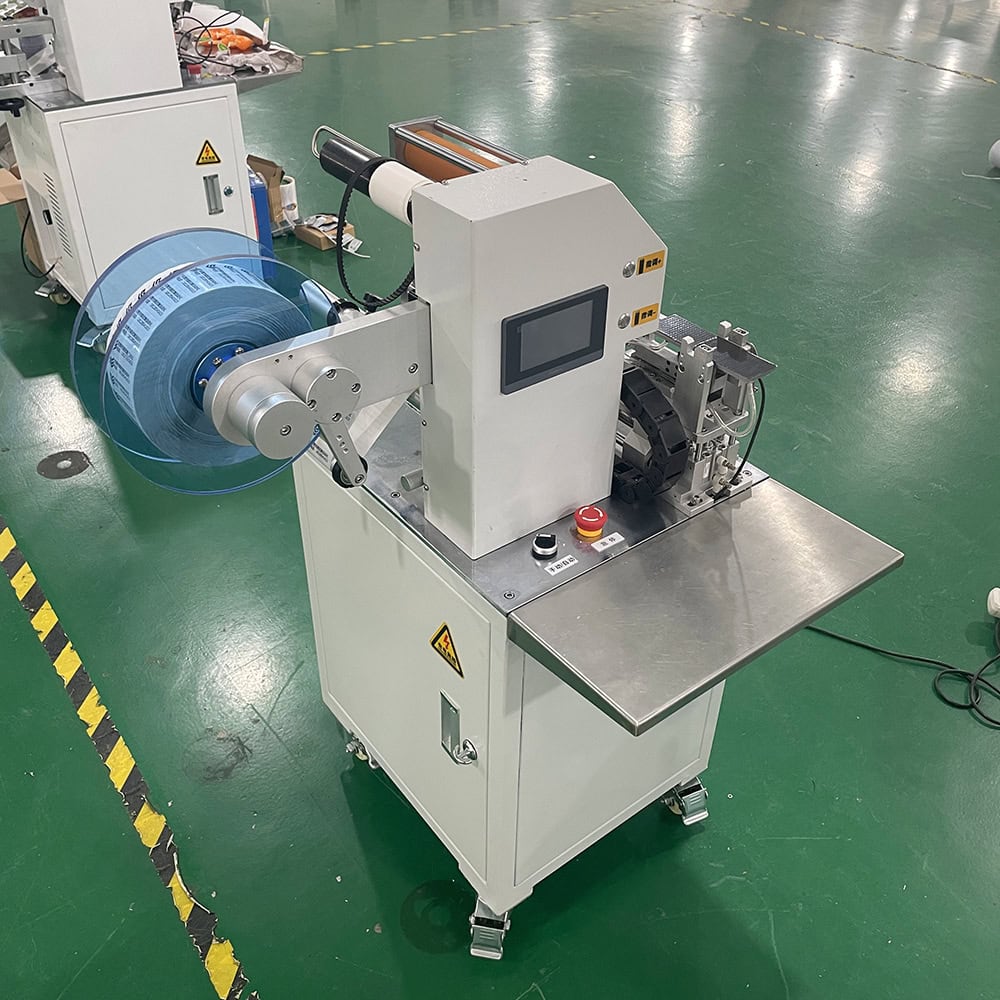

A flag label applicator machine is an automated device designed specifically for labeling long products with circular cross-sections such as wires, tubes, and cables. It simplifies the task of applying labels, ensuring both speed and precision. These machines feature advanced components like unwinding units, pressing mechanisms, and sensors that work in harmony to achieve accurate label placement.

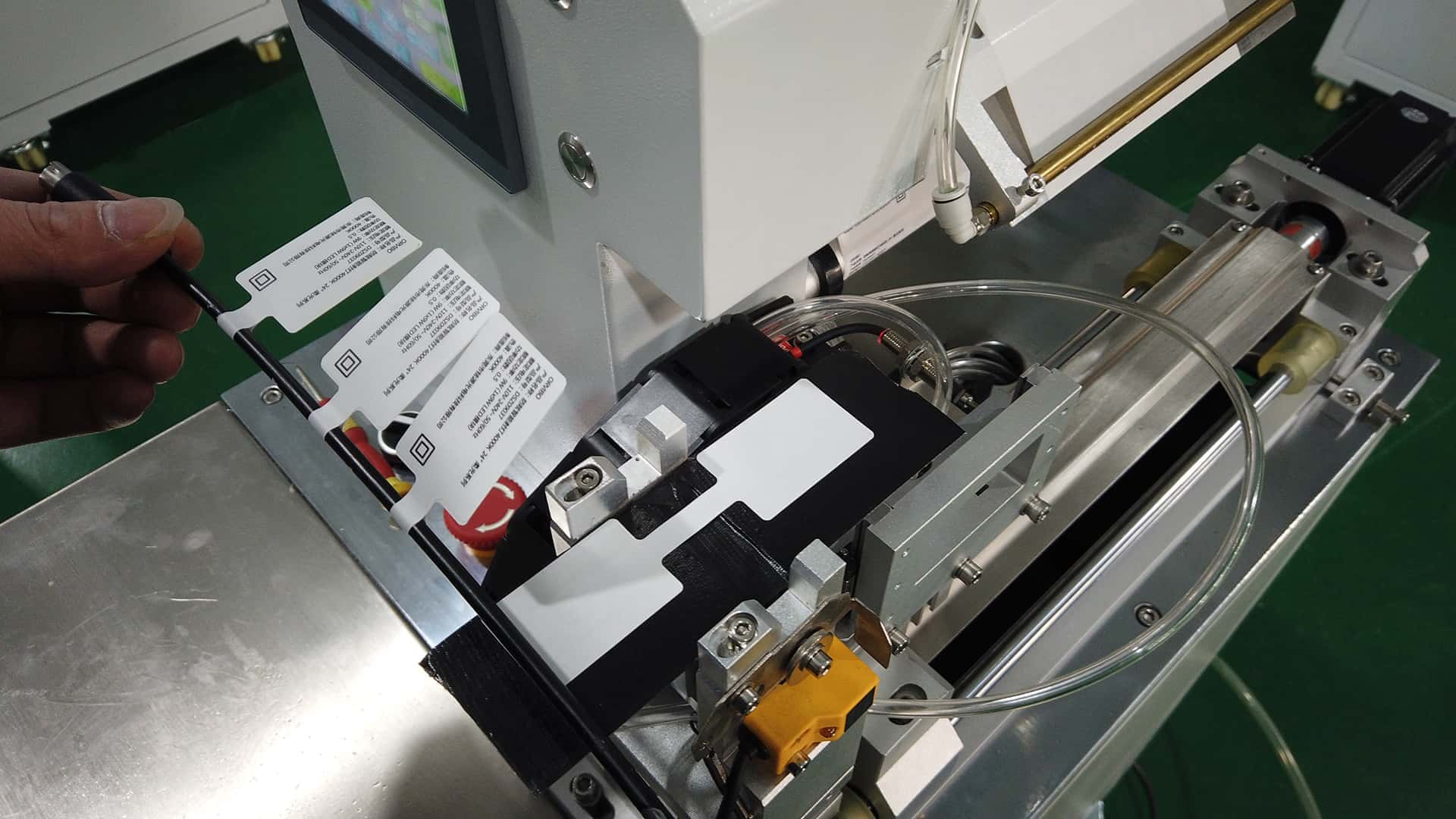

The labeling machine ensures each label is applied securely, leaving part of the label as a flag for easy product identification. This feature is especially valuable in industries that require barcodes or other critical product information to remain visible after application.

How Does Flag Labeling Work?

Flag labeling involves wrapping a label around a product while leaving a portion to extend outward, forming a “flag.” For circular products like cables, this method of labeling provides visibility without compromising the product’s surface.

In flag labeling for circular products, sensors detect the product’s position, and the machine applies the label using a precise folding mechanism. This method is efficient for products that are challenging to label due to their shape, ensuring that the labels adhere firmly while maintaining easy readability.

Components of a Flag Label Applicator Machine

Unwinding and Traction Mechanism

The unwinding unit releases labels, which are then pulled through a traction mechanism. This mechanism peels the label from the backing paper, readying it for application. Proper tension in the traction mechanism ensures smooth operation, preventing misaligned labels and wasted material.

Electric Eye Sensors and PLC Control

An electric eye sensor detects the product’s position and communicates with the machine’s programmable logic controller (PLC). The PLC coordinates the timing and movement of the machine’s components, ensuring the label is applied at the precise moment when the product is in the correct position.

These components are crucial for handling the complexities of circular products, which may require precise alignment to ensure accurate labeling.

Advantages of Flag Label Applicator Machines for Long Circular Products

Precision and Customization

One of the primary advantages of these machines is their ability to offer high labeling accuracy. With features like adjustable label size and sensor settings, they accommodate different product specifications. This precision reduces labeling errors and enhances the product’s final appearance.

The customized labeling machine design allows operators to modify the system for specific product dimensions, making it a versatile solution for a wide range of applications.

Speed and Efficiency

Flag label applicators can handle up to 1,500 pieces per hour, depending on the product size. This high-speed operation significantly increases production efficiency, making these machines an excellent investment for businesses looking to streamline their operations.

Common Applications and Industries

Flag label applicator machines are commonly used in various industries such as electronics, automotive, and packaging. They are ideal for labeling products like electrical wires, data cables, and industrial tubing. These machines also play a crucial role in sectors where regulatory compliance requires accurate and visible labeling of products.

For example, in the automotive industry, cables and tubing must be clearly labeled with barcodes for traceability during manufacturing. In packaging and labeling, these machines ensure that products are marked clearly and consistently.

Troubleshooting Common Issues

Label Misalignment

A common issue in flag labeling is misalignment, which often occurs due to incorrect sensor settings or tension problems within the traction mechanism. This can be solved by recalibrating the sensors and adjusting the label tension to ensure a consistent application.

Label Breakage

Label breakage can occur if the backing paper is too weak or if the machine’s pressing mechanism applies too much pressure. Using high-quality materials and adjusting the machine’s pressure settings can help prevent this issue.

Maintenance and Adjustments for Long-term Efficiency

Regular maintenance of key components like the unwinding unit, traction mechanism, and electric eye sensors is essential for ensuring the long-term efficiency of the machine. Operators should also periodically check and adjust the machine to accommodate different product sizes and shapes.

Routine adjustments to the sensor positions and label tension help to maintain the machine’s accuracy, reducing downtime and ensuring consistent labeling performance.

Conclusion

Flag label applicator machines provide an efficient and precise solution for labeling long products with circular cross-sections. Their ability to handle various product sizes, coupled with advanced automation features, makes them an invaluable asset for industries requiring consistent and high-quality labeling.

You may be interested in: