Improperly sealed cans lead to contamination and spoilage, risking your product quality and business reputation. A reliable can sealing machine prevents these issues by ensuring a tight, secure seal. Let’s explore how it works.

A can sealing machine operates by using the double seaming process, where two operations roll and crimp the can lid to the body, forming an airtight, hermetic seal to prevent leakage and contamination.

Understanding the process behind can sealing machines is crucial for selecting the right equipment and ensuring consistent product quality.

The Double Seaming Process

The core of any can sealing machine is the double seaming process. This method consists of two critical operations:

- First operation: The seaming rollers curl the can lid’s edge beneath the flange of the can body. This ensures that the lid is securely placed.

- Second operation: The rollers then compress the seam, forming a tight bond between the lid and the can, preventing any leakage.

This double seam creates an airtight seal, protecting the product inside from contamination and ensuring its long-term preservation.

Components of a Can Sealing Machine

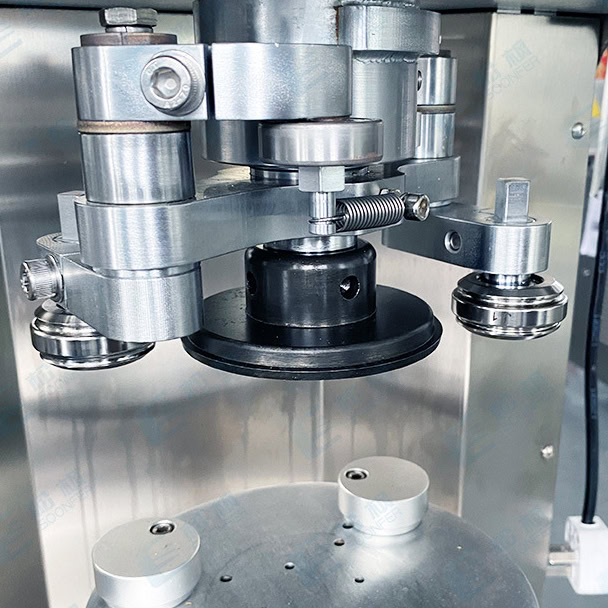

A can sealer contains several essential parts that work together for a smooth sealing process:

- Seaming Rollers: These apply pressure to create the double seam.

- Chuck: Holds the can lid in place while the rollers rotate.

- Turntable: Rotates the can during the sealing process, ensuring even sealing on all sides.

Each of these components must be precisely calibrated and maintained to ensure optimal performance.

Types of Can Sealing Machines

Can sealing machines are available in different types based on automation:

- Manual machines: Require full operator control, ideal for small-scale production.

- Semi-automatic machines: Combine manual and automated functions, perfect for medium-scale operations.

- Fully automatic machines: These handle high-volume production with minimal human intervention, suitable for large factories.

Whether you’re running a small craft brewery or a large food packaging facility, choosing the right machine for your scale can significantly impact efficiency.

Why Sealing is Critical

The primary function of a can sealer is to ensure the contents of the can remain safe and uncontaminated. Proper sealing prevents:

- Contamination: The hermetic seal blocks out harmful bacteria and airborne particles.

- Leakage: A faulty seal may allow liquids or gases to escape, compromising the product quality.

In industries like beverages or food packaging, where cleanliness is paramount, reliable sealing is essential.

Troubleshooting Common Issues

Can sealers, like any machinery, can face problems. Common issues include:

- Loose seams: This can result from improper roller calibration or worn-out machine parts.

- Wrinkled lids: Caused by misalignment of the can or lid during the sealing process.

To maintain the machine’s effectiveness, regular adjustments and preventive maintenance are crucial.

Maintenance and Calibration

Maintaining your can sealing machine ensures smooth operation and a longer lifespan:

- Lubrication of moving parts: Regular lubrication prevents wear and tear.

- Calibration of rollers and chucks: Ensure they are in perfect alignment to create consistent seals.

Neglecting regular maintenance can lead to machine failure and poor sealing results, causing delays in production.

Applications of Can Sealing Machines

Can sealing machines are indispensable in various industries, such as:

- Beverage industry: Sealing cans of soda, beer, and energy drinks.

- Food industry: Ensuring proper sealing of canned goods like soups and vegetables.

These machines offer reliability and efficiency, making them an integral part of the packaging machine line-up in factories.

Advantages of Automatic Can Sealers

Automatic can sealing machines offer several benefits for large-scale production:

- Increased speed: Capable of sealing hundreds of cans per minute, greatly enhancing productivity.

- Consistency: Every can is sealed with uniform quality, reducing errors.

- Labor savings: With minimal manual intervention, you save on labor costs while increasing output.

For high-volume manufacturers, automating the can sealing process ensures both cost-effectiveness and efficiency.

Why Double Seam Seals Are Preferred

The double seam process is widely preferred for can sealing because of its:

- Durability: Two layers of rolled metal provide extra protection against leaks.

- Hermetic seal: It prevents air, moisture, and contaminants from entering the can.

This sealing method is essential in industries that rely on product preservation, such as food and beverage production. It ensures that the product retains its quality from production to consumption.

Conclusions

A can sealing machine uses the double seaming process to provide an airtight, hermetic seal, protecting the product from contamination and leakage. Regular maintenance and calibration ensure long-lasting performance and consistent sealing results, making these machines crucial for various industries.

You may be interested in:

- What Types of Can Labeling Machines Are Best for Different Applications?

- Choosing the Right Beer Can Labeling Machine: A Comprehensive Guide for Brewers

- What are the Features of an Automatic Can Labeling Machine?