Choosing a label manufacturer can be a daunting task. The wrong choice can lead to subpar quality, delayed shipments, and increased costs. However, selecting the right supplier ensures high-quality labels, timely delivery, and a smoother overall process. The solution lies in focusing on critical factors like quality, experience, and customization options.

To choose a reliable label manufacturer, prioritize factors such as experience, label quality, customization options, and technology integration. A trusted supplier ensures product integrity and smooth logistics for your business.

Selecting the right label supplier affects multiple areas of your business, from product presentation to efficient logistics. High-quality, durable labels support both branding and functionality, ensuring seamless operations. Labels often go unnoticed but play a crucial role in consumer satisfaction and operational success.

Expertise and Experience in Labeling

A reliable label manufacturer should have extensive experience in the industry. Expertise in handling diverse labeling requirements, from customized labeling machines to bottle labeling machines, ensures that your product labels meet both aesthetic and functional needs. Whether you’re looking for labels for a bottle filling machine or vacuum packaging machine, an experienced supplier can provide insights into materials, printing methods, and durability.

Why it matters: Experienced manufacturers can troubleshoot problems and offer efficient solutions, ensuring that your labels not only look good but are also functional for your specific needs.

Label Quality Assurance

The quality of the labels produced is crucial for any business that uses labeling in their operations. High-quality labels should resist fading, peeling, or damage under various environmental conditions such as exposure to moisture or UV light. A reliable supplier will use high-quality materials to create labels that stay intact through packaging machines, filling machines, and even transportation.

Why it matters: Low-quality labels can degrade over time, impacting the appearance and integrity of your products. This can cause damage to your brand’s reputation and even affect product functionality in some cases.

Customization Options

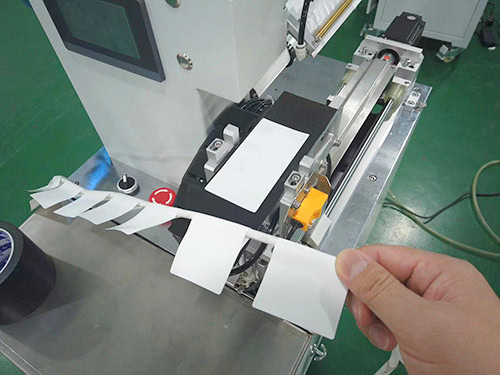

One size does not fit all when it comes to labeling. Whether you need labels for a flat labeling machine or a corner wrap labeling machine, a good manufacturer should offer flexibility in design and material. The ability to customize labels to meet your exact specifications—whether it’s size, material type, or special features—ensures that your labels fit perfectly with your product packaging.

Why it matters: Custom labels help your products stand out on the shelf and ensure that they are functional for specific applications, such as barcode scanning or tracking with label printers.

Technological Advancements

The labeling industry is constantly evolving with new technologies, such as barcode printers and industrial label printers, that improve efficiency and functionality. A forward-thinking supplier will integrate technologies like RFID, temperature-sensitive labels, or digital printing methods, which can provide real-time tracking capabilities and improved operational efficiency.

Why it matters: By staying on top of new technologies, your business can improve its logistics, reduce human error, and enhance the customer experience. For example, liquid filling machines can benefit from labels that track temperature or product integrity throughout the supply chain.

Reliable Delivery and Lead Times

Timing is critical in manufacturing. A label supplier must adhere to deadlines and offer clear timelines for delivery. Whether you’re launching a new product or restocking existing inventory, reliable lead times ensure that your production schedule remains on track. This is especially important when labels are required for bottle capping machines or other filling equipment that relies on consistent, timely delivery.

Why it matters: Delays in label production can disrupt your manufacturing processes, leading to shipping delays or production holdups.

Cost vs. Value

Price is often a key consideration when choosing a supplier, but it’s important to look beyond just the initial cost. Consider the long-term value of the labels, which includes durability, quality, and functionality. A cheap label may save you money upfront but could cost more in the long run if it fades or peels off. Compare suppliers based on their value, not just price.

Why it matters: Opting for cheaper options can lead to higher operational costs if labels fail or need to be replaced frequently. High-quality labels may come with a higher price tag but can result in fewer issues and less downtime.

Strong Customer Support

Good customer support is a sign of a trustworthy supplier. When selecting a label manufacturer, evaluate their responsiveness and willingness to collaborate on your labeling needs. A reputable supplier should offer after-sales support, whether it’s for troubleshooting label printing issues or resolving production delays.

Why it matters: Strong customer support minimizes the risk of operational disruptions. If issues arise, prompt and effective resolution ensures smooth operations without significant downtime or frustration.

Sustainability and Environmental Responsibility

With increasing consumer demand for sustainable products, choosing a supplier that offers eco-friendly labeling solutions is important. Look for manufacturers who use recyclable materials or follow sustainable production practices. Labels that are biodegradable or come from sustainable sources can improve your brand’s reputation.

Why it matters: More consumers are prioritizing sustainability. By choosing an environmentally responsible supplier, you not only contribute to reducing your business’s environmental footprint but also enhance your brand’s appeal.

Volume Flexibility

Whether you’re producing small batches or large-scale orders, a good label manufacturer should be able to handle varying production volumes. Flexibility is particularly important for businesses that may experience fluctuating demand or are scaling up production. For example, whether you’re labeling products with a shrink wrap machine or a powder filling machine, your supplier should be able to meet your changing needs without compromising on quality.

Why it matters: Flexibility ensures that your labeling supplier can accommodate changes in order size, helping your business remain agile and cost-efficient.

Compatibility with Your Business Needs

Ensure that the manufacturer understands your specific business requirements, such as the compatibility of labels with your automatic liquid packaging machine or bottle labeling machine. A reliable supplier will collaborate with you to ensure that the labels align with your machinery, production schedule, and product specifications.

Why it matters: Incompatible labels can cause delays, waste, or malfunction in your machinery, ultimately disrupting production and increasing costs.

Conclusion

Choosing the right label manufacturer is a critical decision that impacts many aspects of your business. By considering factors such as experience, label quality, customization, and technological capabilities, you can ensure that your labeling process runs smoothly and efficiently. This will help boost your product’s appeal, maintain operational efficiency, and enhance customer satisfaction.