When you’re picking a label manufacturer, you don’t want to make bad choices. That can cause you to have delays, bad quality, and a lot of unhappy customers. But if you focus on things like customer service, label material, price, design capabilities, and after-sales support, you can make sure you have a good partner.

To choose a reliable label manufacturer, evaluate their customer service, label material quality, pricing, design capabilities, and after-sales service. Manufacturers with resources related to labeling machines also offer a strong advantage.

So, how do you make sure you have a good label manufacturer? I want to talk about the important things you need to consider when you’re making that decision.

Customer Service

How a manufacturer’s customer service is can be a direct reflection of how reliable they are. You need somebody you can talk to, get quick answers from, and who can solve your problems. A reliable label manufacturer should have a customer service team that can help you quickly and give you advice based on their expertise.

The level of customer service is especially evident when you communicate with the manufacturer about the size, material and other details of the label.

You can’t underestimate the importance of being able to talk to somebody. If they don’t understand what you want, or if they give you vague answers, you’re going to have problems. You need to test their customer service by calling them and seeing how well they respond to your needs.

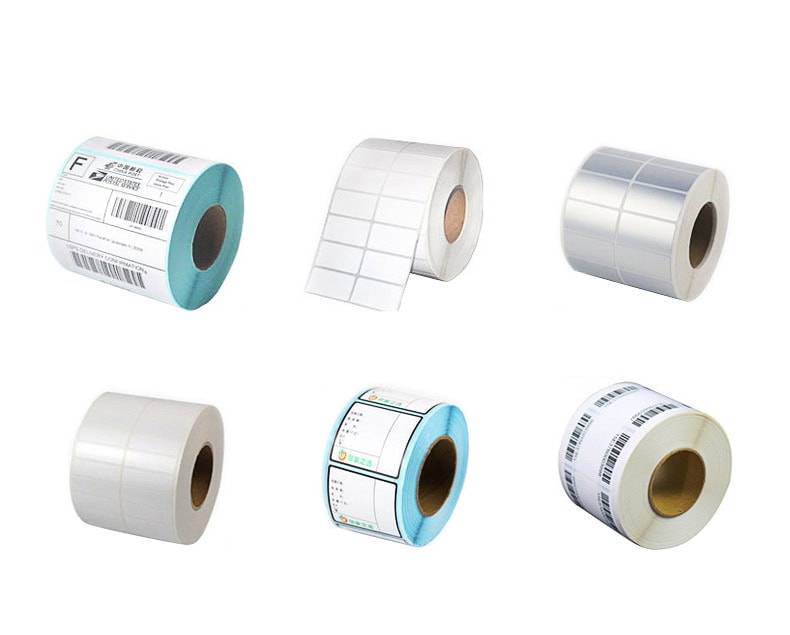

Label Material Quality

The quality of the labels is the most important thing for you to be successful. You need to look at what kind of material they have and see if it’s good enough for you. If you’re in the wire business, for example, you need labels that will stick to wire in harsh environments.

When you talk to people about materials, ask them for samples. Ask them if they can do custom stuff. Do they have labels that work on different surfaces or that are made for industrial use? The life of the label needs to match the life of the product and the conditions it will live in.

Label Price

While quality is important, price is also a big factor. You need to compare prices, but remember that the lowest price isn’t always the best. You need to balance price with quality. Cheap labels are going to give you poor performance, which is going to hurt your brand and cost you more money in the long run because you’ll be replacing or failing.

Make sure you ask for detailed quotes. Ask for prices on the material, design, volume, and shipping. Be careful about hidden fees or prices that seem unusually low. That might mean you’re going to get poor quality or unreliable service.

Label Design Ability

Another important thing to consider when you’re picking a label manufacturer is design capability. You need labels that look good, but you also need labels that have all the information you need and that are compliant with regulations. You need a manufacturer with a design team that can make your labels look good and work right.

If a manufacturer has a design service, it means you don’t have to do it yourself. Instead of you having to come up with a design, they can do it for you. That’s a big deal. You need to ask them if they can do complex designs. If you’re in the wire business, for example, you have very little space to put your label, but you need to get a lot of information on it.

After-Sales Service

One thing a lot of people don’t think about when they’re picking a label manufacturer is what kind of after-sales service they offer. You need to know what happens if you have a problem once you’ve got the labels. You especially need to know what’s going to happen if something goes wrong while you’re putting the labels on your products. If you’re in the wire business, for example, you can’t make wire if you don’t have labels.

Look for guarantees or warranties. Look for people who will help you if you have a problem after you buy. If somebody will help you once you’ve bought the labels, you can probably trust them.

Manufacturers with Labeling Machine Resources

Another big advantage is if you can find a manufacturer who can sell you a labeling machine or recommend one. If they can sell you a labeling machine or have a good source for one, you’ve got a one-stop shop. You won’t have to worry about compatibility between the labels and the machine.

That’s a big deal. If you can find a manufacturer that can sell you a labeling machine or recommend one, you’ve got a one-stop shop. You don’t have to worry about compatibility.

Conclusion

The bottom line is that when you’re picking a label manufacturer, you need to think about customer service, material quality, price, design capability, and after-sales support. If you can find somebody who can give you a machine, that’s a big deal.