Labeling inconsistencies cause product identification issues, leading to delays and potential compliance risks. Using the right labeling machine can streamline production and ensure brand consistency.

Roll labeling machines offer speed and accuracy, while stick-on labeling machines provide flexibility for small runs.

In this article, we’ll explore how these two types of machines differ, helping you make the best decision for your production line.

Understanding Labeling Machines

Labeling machines are critical in applying labels to products and packaging. Whether for branding, compliance, or consumer information, choosing the right machine can enhance efficiency and product presentation. Common labeling machine types include roll and stick-on systems.

Roll Labeling Machines

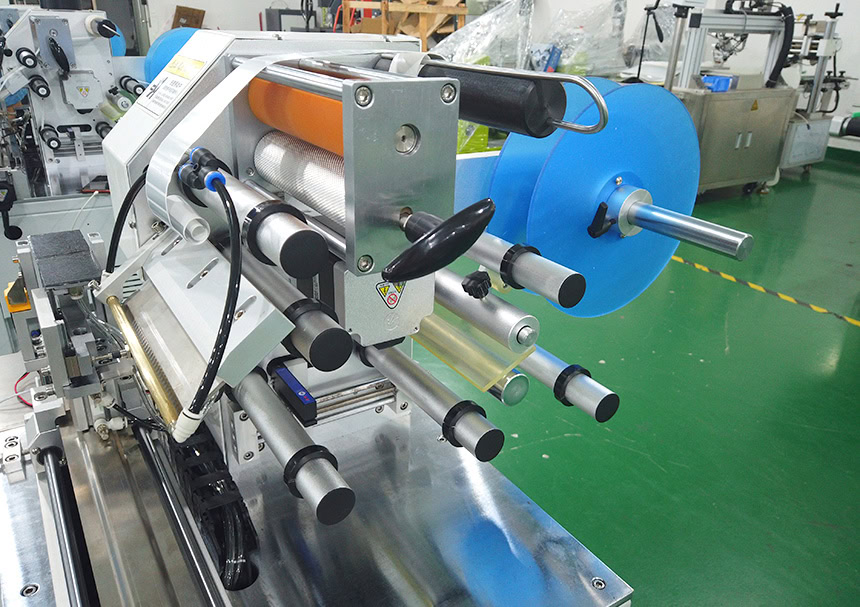

Roll labeling machines use a continuous roll of labels that peel off and are applied to products, typically through automated processes. This system is ideal for high-volume production environments.

Advantages of Roll Labeling Machines

- High Efficiency: Roll labeling machines can process thousands of labels per hour, making them perfect for fast-paced industries like food and beverage production.

- Consistency: These machines offer precise placement, ensuring each product label is perfectly aligned, essential for branding and regulatory compliance.

- Versatility: Whether labeling bottles, cans, or flat surfaces, roll labeling machines are adaptable to a wide range of products.

Many manufacturers, particularly those using Bottle Labeling Machines, rely on roll systems for their speed and accuracy in high-output environments.

Stick-On Labeling Machines

Stick-on labeling machines, or pressure-sensitive systems, apply labels directly onto products without the need for adhesives or water. They are popular for smaller production runs and operations requiring frequent label changes.

Advantages of Stick-On Labeling Machines

- Ease of Use: These machines are straightforward to operate and require less setup time compared to roll systems.

- Flexibility: Stick-on machines can handle a variety of label sizes and shapes, making them ideal for short runs or custom labeling jobs.

- Cost-Effective: With a lower initial investment, stick-on machines are well-suited for small and medium-sized businesses looking for cost efficiency.

Industries utilizing Customized Labeling Machines often favor stick-on systems for their ability to handle unique or irregularly shaped products.

Comparative Analysis

Speed and Efficiency

Roll labeling machines excel in high-speed environments, handling large batches of products with minimal downtime. In contrast, stick-on machines are better suited for operations with lower throughput but higher customization needs.

Accuracy and Consistency

Both machines provide reliable label placement. However, roll labeling machines offer superior precision at higher speeds, making them ideal for industries where uniformity is critical, such as pharmaceuticals and food packaging.

Flexibility

Stick-on machines are unmatched in their ability to switch between different label sizes and shapes quickly, making them preferable for businesses that handle a wide range of products.

Cost Considerations

Stick-on labeling machines typically have a lower upfront cost, while roll labeling machines, though more expensive, offer long-term savings through increased efficiency and reduced manual intervention. Businesses that require high-volume, consistent labeling should opt for roll machines, while those focusing on smaller, varied production lines might choose stick-on systems.

Choosing the Right Machine for Your Needs

When deciding between roll labeling machines and stick-on labeling machines, consider the following:

- Production Volume: If your business processes large quantities of products daily, a roll labeling machine will likely provide better value.

- Product Variety: For companies handling multiple products requiring different label types, a stick-on machine’s flexibility is invaluable.

- Budget: While stick-on machines may have lower upfront costs, roll labeling machines can offer greater long-term savings for large operations.

- Space and Infrastructure: Ensure your facility has the necessary room and infrastructure to accommodate the labeling machine you choose.

Conclusion

The choice between roll labeling machines and stick-on labeling machines depends on your business’s production scale, labeling needs, and budget. Roll machines are ideal for high-volume operations, while stick-on machines provide flexibility for smaller, varied labeling tasks. Careful evaluation of your product line and operational requirements will ensure you select the best machine to optimize your labeling processes.