Cap tightening issues can lead to product leakage, costly returns, and brand damage. Fortunately, cap tightening machines offer an automated solution, providing reliable, precise capping for various industries.

Cap tightening machines work by using rotating mechanisms to secure caps onto containers with consistent torque, preventing leaks and ensuring quality. These machines employ spindle wheels or chuck mechanisms to achieve uniform seals and are indispensable in industries like beverage, pharmaceutical, and personal care.

Cap tightening machines are essential for industries seeking reliable, automated packaging solutions.

Introduction to Cap Tightening Machines

Cap tightening machines are crucial in modern automated packaging processes. They apply uniform force to secure caps onto containers with precision, ensuring a tight seal that protects products and maintains quality. These machines reduce labor costs and minimize human error, making them indispensable in high-production environments such as food and beverage, pharmaceuticals, and personal care.

By using cap tightening machines, companies can enhance their productivity and product integrity. They ensure that caps are applied with optimal torque, preventing over-tightening, which can lead to damaged containers, and under-tightening, which may cause leaks.

Principles of Cap Tightening

Cap tightening machines operate on a simple yet effective principle: gripping and securing caps to bottles or containers using automated torque control. Torque is crucial, as it determines how tightly the cap is applied. Torque controllers in cap tightening machines adjust the force applied, ensuring each cap meets the same specifications for tightness and seal integrity.

Automated torque control not only maintains quality but also extends the life of containers and caps, as the machine applies consistent, controlled pressure. This precision is especially critical in sectors like pharmaceuticals, where a misapplied cap could compromise product safety.

Types of Cap Tightening Machines

There are several types of cap tightening machines, each designed for specific production needs and cap types.

Spindle Cappers

Spindle cappers use a series of spinning wheels to apply caps as containers pass through. This type is ideal for high-speed production environments and can handle a wide range of container shapes and cap sizes. Spindle cappers are known for their speed and versatility.

Chuck Cappers

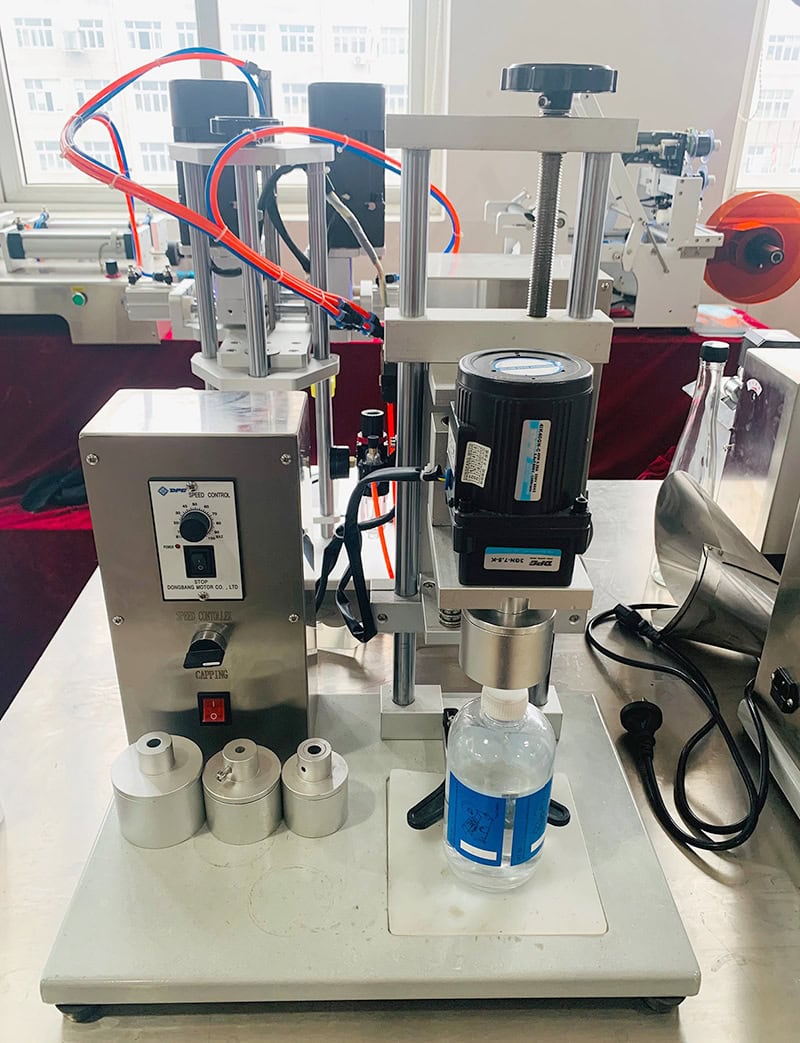

Chuck cappers use a chuck head to grip and twist caps onto containers, providing precise control over torque. This type is highly accurate and often used in industries where cap consistency is essential, such as pharmaceuticals. Chuck cappers ensure a secure fit without damaging the container or cap.

Snap Cappers

Snap cappers use downward pressure to secure caps that do not require twisting, such as plastic snap-on caps. These are commonly used in the food and beverage industry for non-carbonated drinks and other products with flexible plastic caps.

Inline vs. Rotary Capping Machines

Inline capping machines are suitable for low to moderate-speed production lines, as they move containers in a straight line for capping. Rotary machines, however, use a rotating platform that allows multiple containers to be capped simultaneously, achieving much higher speeds, ideal for high-output production.

Mechanisms Behind Cap Tightening

Cap tightening machines employ several key mechanisms to achieve consistent and reliable cap application.

Torque Mechanism

The torque mechanism ensures that each cap is applied with uniform force. Torque settings can be adjusted based on cap and container types, and feedback sensors ensure each cap meets the required specifications. The precise application helps maintain product quality and extends the lifespan of containers and caps.

Servo Motors and Pneumatics

Servo motors and pneumatic components provide the power for cap application. Servo motors allow for high control over speed and torque, while pneumatics offer consistent, repeatable force. Together, they enable fast, accurate, and reliable capping.

Sensors and Feedback Systems

Sensors monitor cap placement, torque levels, and cap orientation to ensure each cap is applied correctly. Feedback systems in these machines can detect any inconsistencies, allowing for immediate adjustments or alerts, which helps maintain high production standards.

Applications in Different Industries

Cap tightening machines have wide applications across various industries due to their adaptability and precision.

Beverage Industry

In the beverage industry, cap tightening machines are crucial for ensuring bottles are tightly sealed, preventing leaks and preserving product carbonation. For carbonated drinks, precise torque control is essential to prevent bottle expansion and cap distortion. A bottle capping machine can provide reliable seals that enhance product stability.

Pharmaceuticals

Pharmaceutical products often require caps with tamper-evident or child-resistant features, making precise capping essential. Cap tightening machines provide the accuracy needed to meet these safety standards, ensuring each bottle is capped to specifications without compromise.

Cosmetics and Personal Care

The cosmetics industry relies on cap-tightening machines for aesthetic and functional packaging, as the appearance of the cap and container is important to consumer appeal. Tightening machines ensure caps are applied uniformly, adding to the product’s visual appeal and usability.

Advantages of Using Cap Tightening Machines

Cap tightening machines offer numerous advantages, making them a smart investment for businesses aiming to optimize their packaging operations.

Increased Production Speed

Automation with cap tightening machines drastically reduces the time per unit, increasing overall production speed. Automated systems eliminate the need for manual cap application, making production faster and more efficient.

Enhanced Consistency and Quality Control

Cap tightening machines provide uniform torque on every cap, ensuring consistency across all products. This precision helps maintain product quality and reduces the chances of leaks, enhancing customer satisfaction.

Cost-Effectiveness

Automated cap tightening reduces labor costs and minimizes product waste from improperly sealed containers. With fewer errors and reduced product rework, companies save time and money in the long run.

Reduced Risk of Leakage and Contamination

Properly sealed caps reduce the risk of leaks and contamination, ensuring product safety and prolonging shelf life. This is particularly important for industries like food and beverages, where maintaining product integrity is essential.

Key Components in Cap Tightening Machines

Cap tightening machines consist of several components that work together to achieve reliable capping.

Spindle or Chuck Mechanisms

These components grip and twist the caps onto containers. Spindles offer speed, while chucks provide precision. Together, they cover a broad range of cap types and container sizes, making the machine versatile.

Conveyors

Conveyors transport containers through the machine, ensuring they reach the capper at the correct angle and height. They play a vital role in the efficiency and speed of the capping process.

Sensors and Torque Adjusters

Sensors detect cap position and ensure each one meets the torque requirements. Torque adjusters allow operators to control the tightness of each cap, maintaining quality and safety standards.

Considerations When Choosing a Cap Tightening Machine

When selecting a cap tightening machine, consider the following factors:

- Cap and Container Compatibility: Different machines are designed for different cap and container types. Ensure the machine matches your production needs.

- Production Speed and Volume Requirements: Higher-speed machines may be necessary for large-scale production.

- Ease of Maintenance and Adjustability: Machines with modular parts are easier to service, reducing downtime and maintenance costs.

Maintenance and Troubleshooting Tips

Regular maintenance is essential for optimal performance of cap tightening machines. Clean and inspect the machine frequently to avoid issues such as misaligned caps or inconsistent torque. Ensure the torque adjusters and sensors are calibrated, as this prevents potential malfunctions and prolongs machine life.

For common troubleshooting, check for proper alignment, inspect sensors for dust or damage, and verify torque settings. Regular maintenance not only extends the machine’s life but also ensures consistent capping quality.

Future Innovations in Cap Tightening Machines

The future of cap tightening machines lies in advanced automation, AI, and sustainability. Innovations in these areas are expected to increase efficiency, reduce material usage, and allow machines to adjust automatically for different cap types and container shapes. With improvements in torque accuracy and adaptability, cap tightening machines will continue to enhance productivity across various industries.

Conclusion

Cap tightening machines are essential in ensuring reliable, consistent capping for a variety of products, preserving product quality and brand reputation. With advances in automation, these machines will continue to play a vital role in efficient and high-quality packaging.