As a bottle cap manufacturer, your customers may often request that you label the caps you supply. Even if you don’t provide this service directly, it’s a common question that customers may ask. So, how should you handle this request effectively?

The best solution is to recommend a specialized labeling machine manufacturer to your customers. Bottle caps vary in size, but generally, they are quite small, which requires precise labeling. Manual labeling is not a feasible option due to its lack of precision, low efficiency, and high labor costs. This compels manufacturers to seek out an automatic labeling machine to accomplish this task.

Understanding the Need for Cap Labeling Machines

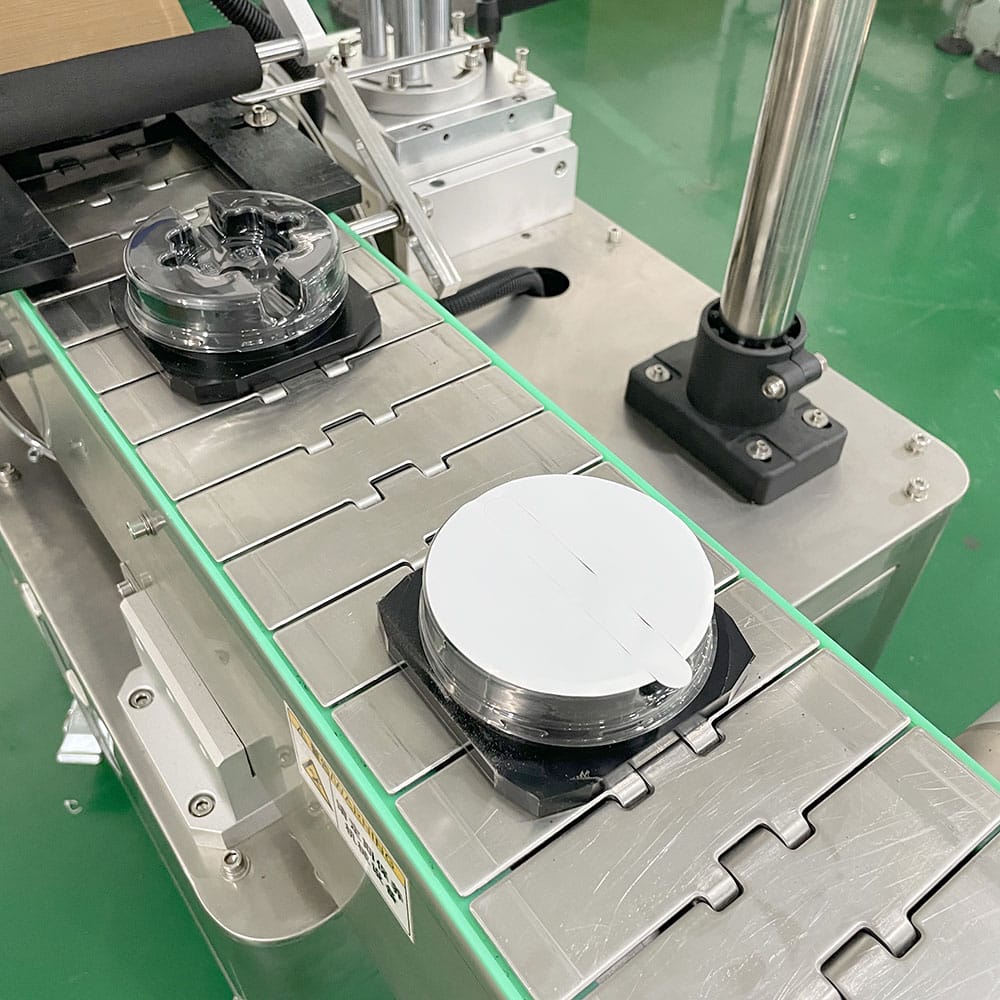

Bottle caps present unique challenges when it comes to labeling. Their small size and often curved surfaces make it difficult to apply labels accurately using manual methods. The precision required to label these caps consistently and effectively is beyond the capabilities of manual labor, especially in high-volume production environments.

This is where a cap labeling machine becomes essential. These machines are specifically designed to handle the intricacies of labeling small caps, ensuring that each label is applied accurately and efficiently. By using a cap labeling machine, manufacturers can meet their customers’ demands while maintaining high standards of quality and productivity.

Why Recommend a Cap Labeling Machine to Your Customers?

When your customers inquire about labeling solutions for bottle caps, the most effective recommendation is to direct them to a reliable manufacturer of cap labeling machines. These machines are designed to handle the unique challenges posed by small, often delicate, bottle caps. They offer several key advantages:

- High Precision: Cap labeling machines are engineered to apply labels with extreme accuracy, ensuring that even the smallest caps are labeled consistently.

- Efficiency: These machines can label caps at a much faster rate than manual methods, significantly increasing production efficiency.

- Cost-Effectiveness: While the initial investment in a cap labeling machine may be substantial, the reduction in labor costs and increase in output make it a cost-effective solution in the long run.

By recommending a cap labeling machine, you help your customers enhance their production capabilities, reduce costs, and ensure that their products are labeled to the highest standards.

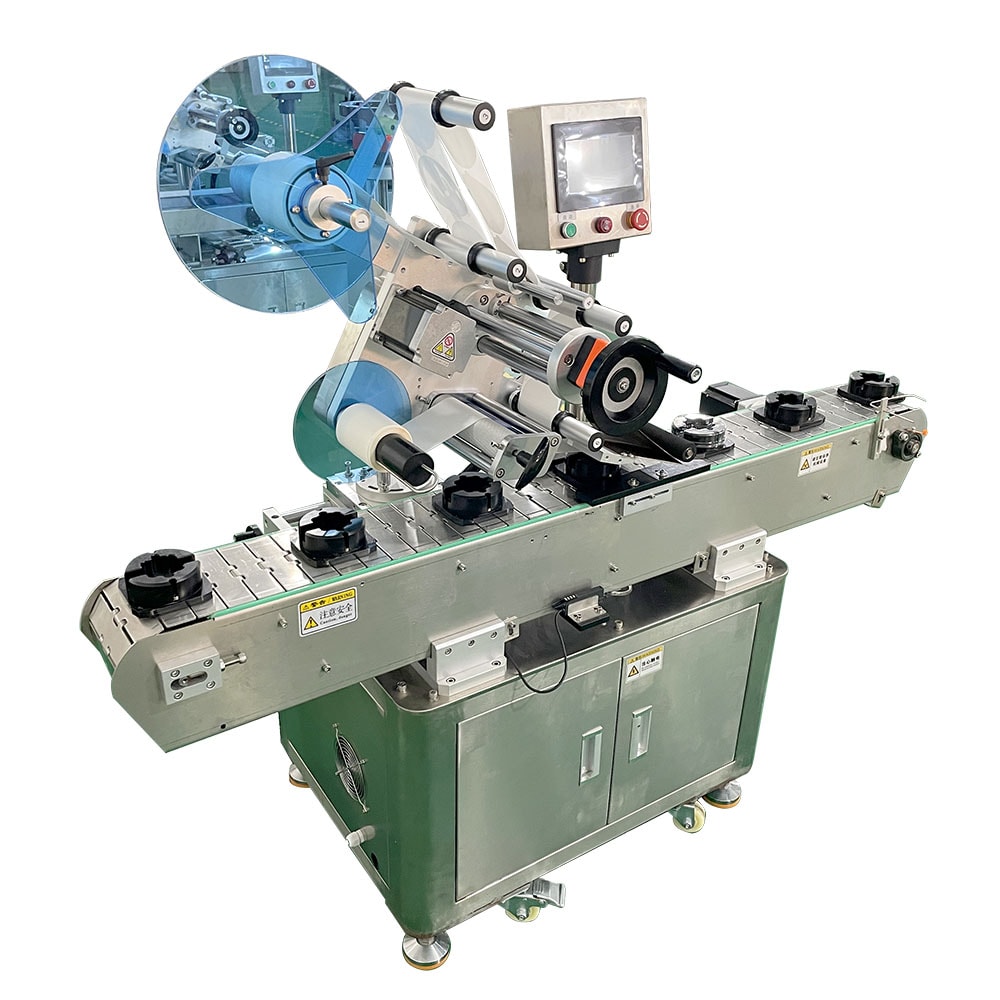

Automatic Solutions for Bottle Cap Labeling

Given the complexities of labeling bottle caps, an automatic bottle label machine is often the best solution. These machines are not only capable of labeling bottles but can also be adapted for use with caps, providing a versatile solution for manufacturers.

For businesses that deal with both bottles and caps, investing in an automatic labeling machine that handles both tasks can streamline operations. This dual-functionality ensures that all labeling needs are met with a single piece of equipment, reducing the need for multiple machines and simplifying the production process.

Additionally, automatic labeling machines offer the precision and speed required to keep up with high-volume production, ensuring that every cap is labeled perfectly without slowing down the production line.

Conclusion: Meeting Your Customers’ Labeling Needs

When your customers ask about labeling solutions for bottle caps, the most effective way to address their needs is to recommend a cap labeling machine. These machines offer the precision, efficiency, and cost-effectiveness that manual labeling simply cannot match. By guiding your customers toward the right equipment, you help them enhance their production capabilities and meet their labeling requirements with confidence.

For those who also need a versatile solution for both bottles and caps, consider recommending an automatic bottle label machine that can handle multiple labeling tasks efficiently. This approach not only meets their immediate needs but also prepares them for future production challenges.