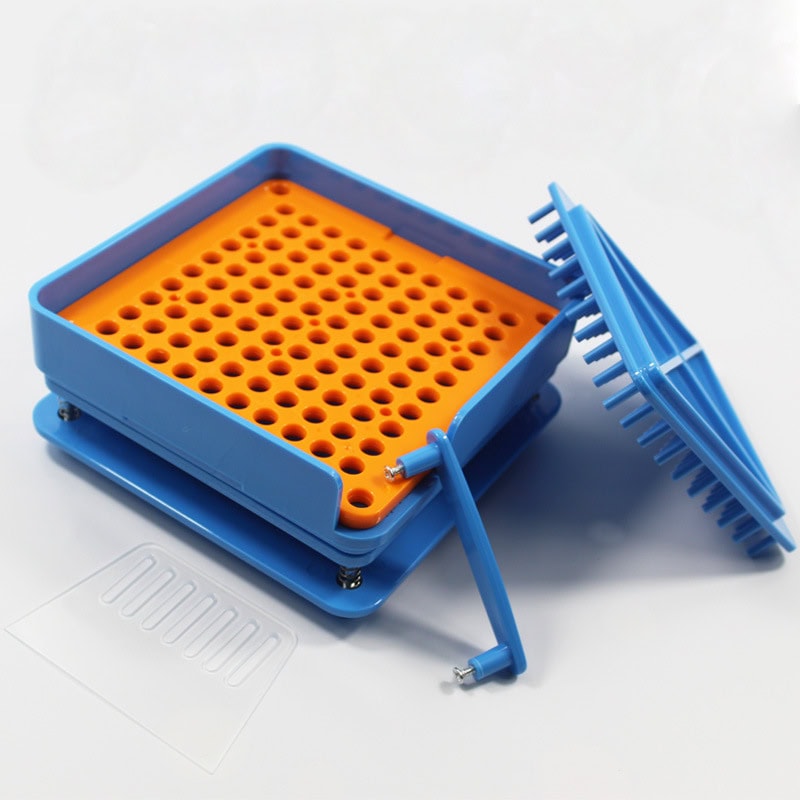

Manual capsule filling machines are cost-effective but come with significant drawbacks. Inefficiencies, inconsistent results, and labor-intensiveness could hinder productivity. Understanding these issues helps in deciding whether to switch to automated systems.

Manual capsule filling machines face challenges such as low productivity, higher human error rates, and operator fatigue, making them unsuitable for large-scale operations.

Discover the most notable disadvantages of manual capsule filling machines and explore their implications on efficiency and scalability.

Limited Production Capacity

Manual capsule filling machines are inherently designed for small-scale production, making them unsuitable for large-scale pharmaceutical or supplement manufacturing. Unlike automated systems such as a capsule filling machine, their output speed is limited, often requiring hours to produce what a fully automated system could complete in minutes. This restricts productivity and makes scaling operations difficult.

For businesses requiring a higher throughput, such as companies utilizing industrial shrink wrap or other mass-production systems, manual capsule machines cannot keep up with demand.

High Dependency on Skilled Operators

Operating a manual capsule filling machine requires skilled workers who understand the delicate process of aligning, filling, and sealing capsules. The margin for error is small, and inexperienced operators may inadvertently increase waste or produce substandard products.

Additionally, fatigue and inconsistent handling can lead to errors, further highlighting the inefficiency of manual systems. This dependency creates bottlenecks, especially in high-pressure production environments, where equipment such as a rolling bottle labeling machine offers more stability.

Time-Consuming Process

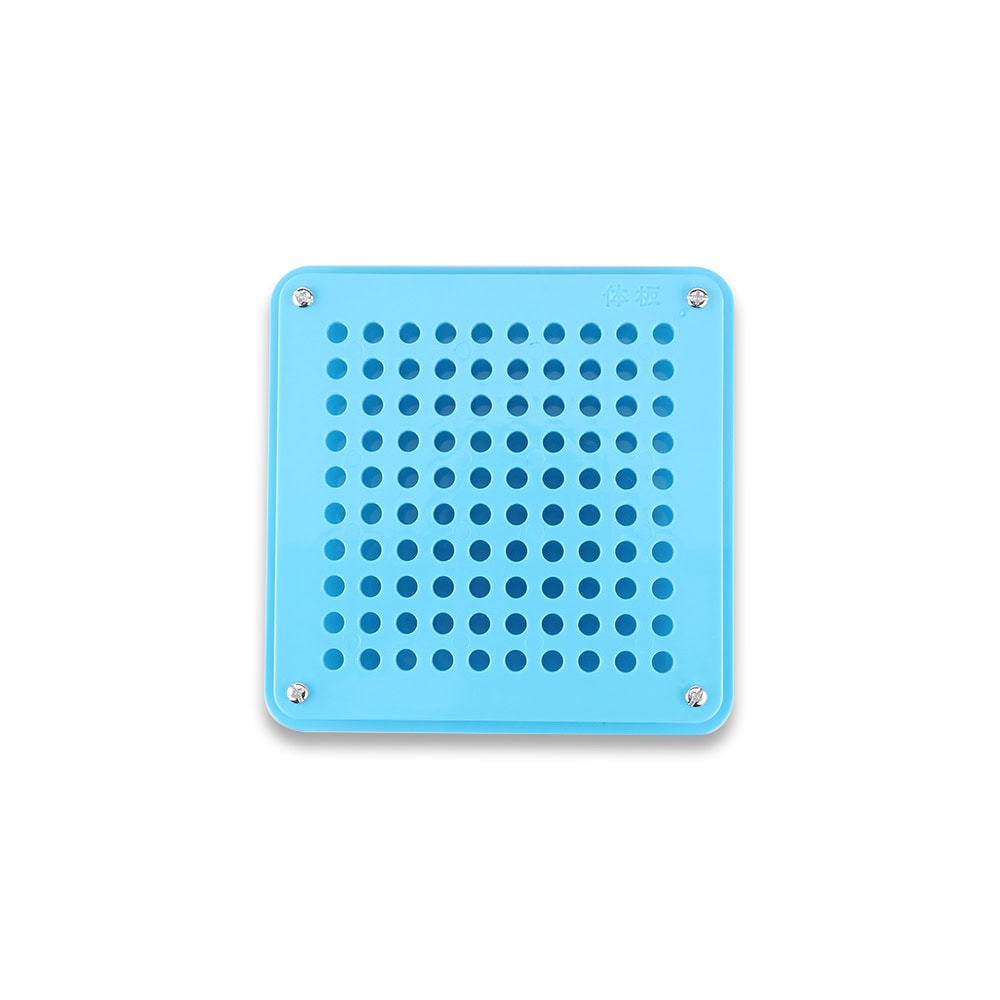

The manual capsule filling process is labor-intensive and slow, often involving repetitive steps such as aligning capsules, pouring powder, and sealing. These tasks must be repeated for every batch, consuming valuable time.

Businesses aiming to achieve production efficiency—similar to the capabilities provided by a bottle labeling machine—will find manual systems inadequate, especially when deadlines and high-volume orders are involved.

Lack of Precision and Consistency

Unlike automated capsule filling systems, manual machines often result in uneven powder distribution and improper capsule sealing. This inconsistency can lead to dosage errors, compromising product quality and regulatory compliance.

In industries that demand precision, such as pharmaceuticals, manual systems struggle to meet standards. Businesses often invest in automated machines, like industrial label printers, to maintain consistent results and ensure accuracy.

Higher Error Rates

Errors are more frequent with manual capsule filling machines, as they rely on human intervention for every step. Common mistakes include improper capsule alignment, uneven filling, or damage during sealing.

Such errors necessitate additional quality checks, increasing production time and costs. Automated systems, including advanced positioning bottle labeling machines, can minimize such issues significantly.

Unsuitability for Complex Formulations

Manual capsule filling machines are limited in handling complex capsule designs or multi-component formulations. This restricts businesses from offering innovative or varied product ranges.

For example, companies producing dual-colored capsules or layered formulations may find manual systems entirely inadequate.

Labor-Intensive Operation

Continuous manual intervention makes capsule filling a resource-heavy operation. Labor costs increase as multiple workers are needed to operate, monitor, and perform quality control.

By comparison, automated systems, like a flat labeling machine, reduce dependency on manual labor, streamlining production and improving cost efficiency.

Maintenance Challenges

Cleaning and maintaining manual capsule filling machines can be cumbersome, particularly in environments requiring rigorous sanitation standards. Without proper cleaning, the risk of cross-contamination rises significantly.

Conversely, automated systems with self-cleaning capabilities or modular designs ensure better hygiene and faster maintenance.

Increased Operational Costs

Though manual machines have a lower upfront cost, their inefficiencies lead to higher long-term expenses. Operational costs, including labor, error correction, and time wastage, make manual systems less economical over time.

For businesses using modern equipment like an automatic liquid packaging machine, the return on investment far outweighs the savings of manual systems.

Limited Scalability

As businesses grow, manual capsule filling machines cannot meet escalating production demands. Transitioning to automated equipment often becomes inevitable, requiring significant reinvestment.

To avoid production bottlenecks and maintain competitiveness, many businesses turn to advanced systems like automated filling or labeling machines, such as a flag labeling machine.

Conclusion

While manual capsule filling machines offer affordability and simplicity, their limitations in capacity, precision, and scalability make them unsuitable for large-scale or quality-sensitive operations. Businesses should weigh these factors before choosing a solution.