Inefficient packaging leads to damaged goods and higher transportation costs. PET strapping machines enhance packaging security, essential for safe, cost-effective product transit.

A PET strapping machine applies PET (polyethylene terephthalate) straps to secure packages with high strength and durability, providing reliable support for products during transport. This makes it ideal for use in multiple industries.

Explore the role and benefits of PET strapping machines, their functionality, and their advantages over other materials.

Understanding PET Strapping Machines

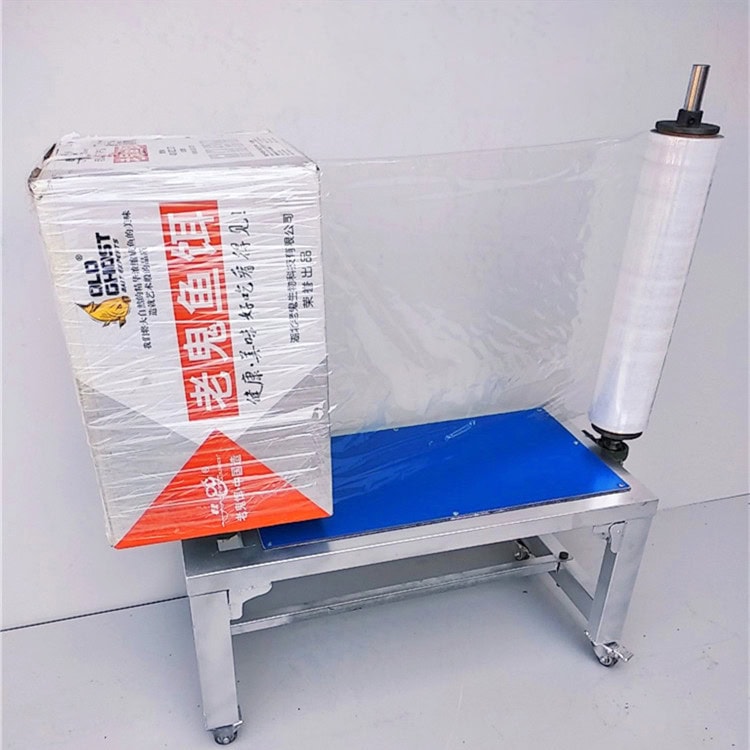

A PET strapping machine is designed to apply PET straps securely around packages, ensuring they remain tightly bound during handling and transportation. PET straps, made from polyethylene terephthalate, offer higher strength and resilience than other types of plastic straps, which makes them especially suited for securing larger or heavier packages.

Unlike traditional methods, which may use materials prone to breaking under stress, PET straps provide durable support, reducing the risk of package movement or damage in transit. PET strapping is highly valued across industries because it can retain tension without stretching or snapping, making it reliable for packaging solutions involving rigorous transportation.

Key Components of a PET Strapping Machine

PET strapping machines come equipped with several core components, which allow them to apply high-tension strapping efficiently and accurately:

- Unwinding Unit: Holds and releases the PET strapping roll smoothly.

- Tensioning Mechanism: Applies the correct level of tension to secure the strapping.

- Sealing System: Seals the PET strap securely, often through a combination of heat and pressure, to ensure it doesn’t loosen during transportation.

- Control Panel: Allows operators to adjust machine parameters, such as tension levels, to fit the specifications of each packaging task.

These components work together seamlessly, helping the machine apply consistent strapping across a range of packaging applications, whether for shipping large pallets or smaller containers.

Types of PET Strapping Machines

PET strapping machines are available in several configurations to suit various operational needs:

- Handheld vs. Automatic Machines: Handheld PET strapping machines are portable and allow for flexible usage across locations, making them a popular choice for smaller operations. Automatic machines, however, are stationary and typically offer higher throughput with more consistent tension application, making them ideal for high-volume environments.

- Battery-Powered and Pneumatic Options: Battery-operated PET strapping machines allow for easy mobility, while pneumatic options are powered by compressed air, delivering the high tension needed for industrial applications. Both types can be beneficial depending on the specific requirements of a production line.

Benefits of Using PET in Strapping

PET straps are recognized for their exceptional strength and flexibility, which provide key benefits over other materials such as polypropylene (PP):

- Strength and Flexibility: PET offers high tensile strength, ensuring that straps do not stretch, loosen, or snap under pressure, making it highly suitable for heavy-duty packaging needs.

- Environmental Sustainability: PET is recyclable, contributing to a more sustainable packaging process. Compared to other non-recyclable materials, PET’s eco-friendly nature is a major advantage for companies aiming to reduce their environmental footprint.

By choosing PET for packaging, companies ensure that their products are well-protected and that their packaging practices align with modern sustainability goals.

Applications Across Industries

PET strapping machines find applications across a wide range of industries due to their versatility and strength.

- Primary Uses: PET strapping is used to secure heavy products, stack pallets, or bundle multiple items together, ensuring safe storage and transport. Industries such as construction, logistics, and manufacturing widely rely on PET strapping for its reliable performance.

- Versatile Usage: PET straps can secure everything from large pallets of construction materials to individual boxes of consumer goods, making them highly adaptable for different business needs.

Comparison with PP (Polypropylene) Strapping

One common question is how PET strapping compares to polypropylene (PP) strapping. While both materials are used in packaging, each has unique properties:

- Material Strength: PET has a significantly higher tensile strength than PP, making it ideal for heavier loads. In contrast, PP is often used for lighter applications where flexibility is more critical than strength.

- Heat Resistance: PET’s superior heat resistance means it can withstand temperature fluctuations during transit without losing tension or snapping, which is particularly useful in long-haul shipments across varying climates.

For applications that require high-strength strapping, such as industrial packaging, PET’s advantages make it the preferred material.

How to Operate a PET Strapping Machine

Operating a PET strapping machine is generally straightforward with proper training:

- Setup and Calibration: Start by loading a roll of PET strapping onto the unwinding unit and threading it through the machine’s rollers. Adjust the tension settings based on the weight and size of the package.

- Strap Application: Position the package under the machine, ensuring it aligns with the strapping mechanism. Activate the machine to apply the strap around the package and seal it securely.

- Safety Measures: Operators should be trained in machine usage and maintenance to prevent malfunctions. Regular checks ensure optimal performance, preventing issues like strap misalignment or tension inconsistencies.

For businesses that need high-speed packaging, automated PET strapping machines are recommended, as they offer faster application and reduce the risk of human error.

Advantages of Automatic PET Strapping Machines

Automatic PET strapping machines provide several benefits for companies with high-volume packaging needs:

- Enhanced Efficiency: Automating the strapping process speeds up production lines, reducing labor and handling time.

- Consistency and Reliability: Automated machines apply a consistent tension to each strap, ensuring packages are uniformly secured, which minimizes the risk of strap breakage or loosening.

Using an automatic strapping machine can significantly boost the productivity and reliability of packaging operations, making it ideal for larger warehouses and production facilities.

Maintenance and Troubleshooting

To maintain a PET strapping machine’s performance, routine maintenance is essential:

- Routine Checks: Inspect components such as the tensioners and cutters regularly to ensure they are in good condition.

- Common Issues: Misaligned straps, insufficient tension, and cutter wear are typical problems. Regularly recalibrating and servicing the machine can help avoid these issues.

Maintenance routines should be part of daily operations, ensuring that the machine remains operational with minimal downtime and preventing costly disruptions.

Future Trends in PET Strapping Technology

Advancements in PET strapping technology are opening up new possibilities in the packaging industry:

- Smart Integration: Newer PET strapping machines come with smart controls and IoT integration, allowing real-time monitoring of tension, strap usage, and machine diagnostics.

- Sustainable Innovations: The development of eco-friendly PET materials is helping companies reduce their environmental impact, with some models even supporting biodegradable PET strapping.

The trend toward more sustainable, automated, and tech-enabled strapping solutions reflects the packaging industry’s growing focus on efficiency and environmental responsibility.

Conclusion

PET strapping machines are essential for industries that require reliable, high-strength packaging solutions. Their efficiency, combined with the eco-friendly nature of PET, makes them a vital tool in modern logistics and packaging. For further details on choosing a PET strapping machine suited to your needs, consider visiting LabeMachine’s packaging machine page to explore various models.