Pallet loads can shift, fall over, and get damaged in transit, which causes accidents, delays, and extra costs. If you don’t wrap your pallets consistently, you’re asking for something to get damaged, which will hurt your profits and make your customers mad. A shrink wrap machine is a great way to consistently secure your pallet load for safe travel.

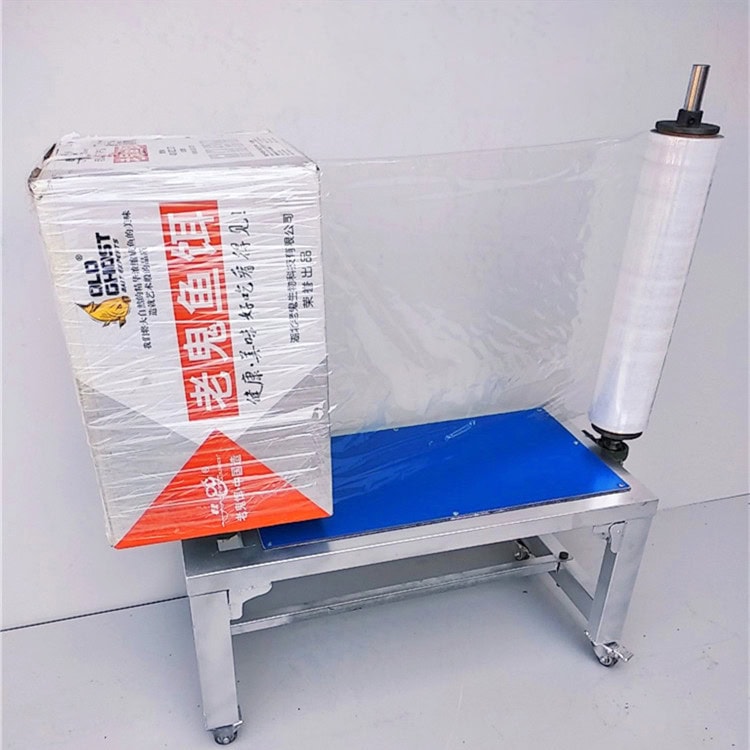

A pallet shrink wrap machine automates the process of wrapping stretch film around pallets, stabilizing loads by applying a tight, protective layer of plastic film around them.

In this article, we’ll talk about what a pallet shrink wrap machine is, the different types of machines you can get, and why they’re important for your packaging and shipping processes.

What is a Pallet Shrink Wrap Machine?

A pallet shrink wrap machine is an automated device designed to apply stretch film around palletized goods, securing them tightly for transportation or storage. The machine stretches the film as it wraps, providing a firm, consistent hold, which protects the items from damage, dust, and external elements.

By using a shrink wrap machine, businesses can improve the efficiency of their packaging process, reduce labor costs, and increase load stability, ensuring products arrive at their destination intact.

How Does a Pallet Shrink Wrap Machine Work?

Pallet shrink wrap machines operate by rotating a loaded pallet on a turntable or moving a wrapping arm around the pallet while the film is applied. The process begins with placing the pallet on the machine, adjusting settings for the desired wrap tightness and speed, and initiating the wrapping cycle.

- Turntable models rotate the pallet while a stationary arm applies the film.

- Rotary arm models hold the pallet still while the wrapping arm moves around it.

- Robotic pallet wrappers move around the pallet, making them ideal for wrapping multiple pallets in different areas.

The stretch film, pre-stretched by the machine, clings tightly to the pallet, providing a secure wrap that prevents movement during transit.

Types of Pallet Shrink Wrap Machines

Pallet shrink wrap machines come in various configurations to suit different operational needs.

Turntable Stretch Wrappers

Turntable stretch wrappers rotate the pallet while the wrapping arm remains stationary. This is one of the most common types, ideal for businesses that process a moderate number of pallets daily. The machine allows for uniform and secure wrapping, making it effective for stabilizing loads.

Rotary Arm Stretch Wrappers

Rotary arm stretch wrappers keep the pallet stationary while the wrapping arm rotates around it. These machines are ideal for larger or unstable loads that cannot be rotated without risking damage.

Robotic Pallet Wrappers

Robotic pallet wrappers are highly versatile and portable. Instead of using a turntable or fixed arm, the robot moves around the pallet to wrap it. This type is suitable for warehouses that handle a wide variety of pallets in different locations.

Key Features of Pallet Shrink Wrap Machines

Pallet shrink wrap machines offer several features that enhance their efficiency and adaptability to various packaging needs:

- Pre-Stretch Function: Many machines stretch the film before applying it, reducing the amount of film used while maintaining secure wrapping.

- Adjustable Film Tension: Operators can control the tightness of the wrap depending on the type of load, ensuring optimal stability.

- Variable Speed Settings: Machines allow the adjustment of wrapping speed to suit different pallet sizes and weights, improving flexibility in operations.

Benefits of Using a Pallet Shrink Wrap Machine

Pallet shrink wrap machines provide significant advantages for businesses involved in shipping and logistics.

Time and Cost Efficiency

By automating the wrapping process, these machines save time and reduce the need for manual labor, allowing businesses to wrap more pallets in less time and at a lower cost. Automatic film stretching also reduces material waste, making it a cost-effective solution.

Load Stability

Shrink wrapping provides a tight, uniform layer of protection that prevents palletized goods from shifting during transport. This ensures that even delicate items arrive safely and in their original condition.

Protection from External Elements

The stretch film used in pallet wrapping offers an additional layer of protection from dust, dirt, moisture, and tampering. This is particularly important for goods stored outdoors or in dusty environments.

How Many Times Should You Shrink Wrap a Pallet?

To ensure optimal load stability, it is recommended to wrap a pallet at least three to four times. This number can vary depending on the weight and type of load. For heavier or unstable loads, more wraps may be required to prevent any movement during transit.

Common Applications of Pallet Shrink Wrap Machines

Pallet shrink wrap machines are used across multiple industries for packaging and shipping. Common applications include:

- Logistics and Warehousing: Ensuring that goods are securely wrapped for transport.

- Manufacturing: Wrapping finished products for storage or shipment.

- Retail: Protecting bulk orders or palletized goods in storage and transit.

Manual vs. Automatic Pallet Shrink Wrap Machines

Manual Pallet Wrappers

Manual machines require the operator to control the application of the film. While cheaper than automatic options, manual wrappers are labor-intensive and slower, making them suitable for businesses with low pallet volumes or occasional wrapping needs.

Automatic Pallet Wrappers

Automatic machines, on the other hand, streamline the wrapping process, requiring minimal operator involvement. They are ideal for high-volume operations, providing consistency, speed, and greater control over wrap tension and speed.

How to Use a Pallet Shrink Wrap Machine

Using a pallet shrink wrap machine is straightforward:

- Place the pallet on the machine: Position the pallet correctly on the turntable or in the wrapping zone.

- Adjust machine settings: Set the film tension, speed, and number of wraps required based on the load.

- Start the wrapping process: Activate the machine, which will then automatically wrap the pallet.

- Secure the film: Once wrapping is complete, cut the film and secure the loose end to the load.

Alternatives to Pallet Shrink Wrapping

While shrink wrapping is the most popular method for securing pallets, there are alternatives, including:

- Stretch Nets: Used for breathable wrapping, often for products that need ventilation.

- Pallet Strapping: Involves using plastic or metal straps to secure loads. However, it doesn’t offer the same level of protection against dust or moisture as shrink wrap.

Conclusion

Pallet shrink wrap machines are indispensable for businesses that need to secure palletized loads efficiently. These machines improve load stability, reduce damage during transit, and provide a fast, cost-effective solution for packaging operations.