I can’t imagine anyone using manual labeling anymore, especially on production lines. It’s a way to be inefficient and have poor labeling accuracy. Even for small labeling operations, we can use a semi-automatic self-adhesive labeling machine to help us improve results.

An automatic self-adhesive labeling machine is more efficient and provides fast, accurate and reliable labeling. Increase production capacity and reduce human error.

What is an Automatic Sticker Labeling Machine?

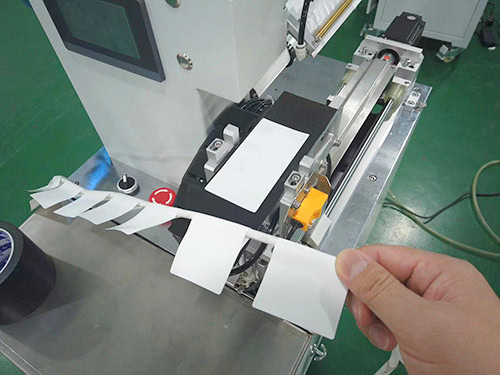

An automatic sticker labeling machine is a piece of fancy equipment that puts labels on your products. It does it without any help from humans, which means you don’t need as many people working for you to put labels on your products. You’ll see these used to put labels on bottles, boxes, cans, and other types of packaging in industries like food and beverage, cosmetics and pharmaceuticals.

The machine has sensors, rollers, and all kinds of cool stuff built into it to make sure that every label ends up in the same place in the same way every single time. You can use it as part of your production line, or you can use it as a standalone machine. This technology helps you make sure that your labels are always put on straight and in the right place.

How Does an Automatic Sticker Labeling Machine Work?

How it works is you put your product on a conveyor system. The machine has sensors to tell it when your product is there and when the label is there. When it sees both, it will put the label on your product using a roller or suction. The machine’s controls make sure the label goes on in the right spot.

Machines like this have controls that you can use to tell the machine how big your product is and where you want the label to go. That way, you can use it for different products. Some of the fancier ones have programmable logic controllers (PLCs) that control how fast the label goes on so that it lines up with your product.

Types of Automatic Sticker Labeling Machines

There are several different types of automatic sticker labeling machines. One of the most common is the automatic bottle labeling machine. These are used a lot in the beverage and pharmaceutical industries. They can put labels on round bottles, oval bottles, or bottles that are shaped weird.

Another type of machine is the flat surface labeling machine. These are used for things like boxes, cartons, electronics, and stuff like that. They make sure the label goes on straight and in the right place. Both types can handle different size labels and different shaped products.

Key Features of Automatic Sticker Labeling Machines

These machines are known for their accuracy, sometimes as precise as ±0.5mm. That means your product will get a label put on it the same way every time. You’ll also be able to adjust the machine to work with different sized products and products that are shaped differently.

These machines are fast. They can put labels on thousands of products per hour. They have sensors built in to tell them when labels are there and when products are there. This ensures that the label goes on every time without any problems.

Benefits of Using an Automatic Sticker Labeling Machine

The main reason you want to use an automatic sticker labeling machine is to save time. It does a job that would take a lot of time for a person to do. By using this machine, you free up time for other things that need to be done on your production line. This can help you get your products out faster and make more money.

The other big reason you want to use one of these is that it’s cheaper. You don’t have to pay a person to do it. You also reduce the chance of mistakes. When you’re doing branding and packaging, you want the label to go on the same way every time.

Factors Affecting the Price of an Automatic Sticker Labeling Machine

The price of these machines can vary. One of the things that affect the price is the size and capacity of the machine. The bigger the machine, the more it’s going to cost. If you need to do a lot of products, you’ll need a big machine. If you need to change the size of labels or handle different shaped products, it’s going to cost more.

If you buy a machine from a big-name company that has all the bells and whistles like programmable controls and high-speed sensors, you’ll pay more for it. These machines use the latest technology to work fast and not break down, which could be worth the extra cost for you. If you need to know the price of a specific labeling machine, please contact us.

Applications of Automatic Sticker Labeling Machines

Automatic sticker labeling machines are used in a lot of different industries. In the food and beverage industry, you’ll find them used to put labels on bottles and jars that contain things like juice, sauce, or dairy products. These machines make sure the labels go on without any wrinkles, which makes your products look good and sell more.

In the pharmaceutical industry, you need to be even more careful. You’ll see these machines used to put labels on medicine bottles. You have to make sure that everything is right there on the label. You don’t want to give people the wrong medicine.

Maintenance and Troubleshooting of Sticker Labeling Machines

You need to take care of your machine to make sure it works right and lasts a long time. You need to clean the sensors and rollers to make sure that junk doesn’t get in the way of your labels. You need to check it to make sure the labels are fed in there right. You need to make sure the labels go on there right. You need to calibrate your machine so that it puts the label on straight and doesn’t skip labels.

If you have trouble with your machine, you might have problems with the labels not going on there right, the sensors not working, or the machine not turning on. You might be able to fix the labels not going on right by adjusting the tension on the label roll. You can fix the sensors by recalibrating them. If something breaks on your machine, you might need to get it fixed by a professional.

Final Thoughts

These machines can help you make more money by letting you put labels on your products faster, saving you time, and helping you avoid mistakes. If you’re going to buy one of these machines, you should buy a good one. It will help you make more money.