Food manufacturers have to worry about all kinds of labeling laws. If you put the wrong label on your food, it could be a disaster. You could have to do a recall, get a big fine, or make people mad at you. The right machine will make this part of your operation a lot easier.

The best labeling machine for the food industry depends on label types, regulations, and specific needs, including compliance with FDA standards and printing technologies.

By understanding the different types of machines, the laws, and how you can do it, you can make a good choice for your food business.

What Are the Different Types of Labeling Machines?

Labeling machines for the food industry come in various forms, each tailored to different packaging styles. Here are some common types:

- Carton Labeling Machine: This machine applies labels to cartons, ideal for outer packaging in food products.

- Wrap Around Labeling Machine: Often used for bottles, this machine wraps the label around the entire product.

- Labeling Machine for Can Body: This is specialized for cylindrical cans, offering precise label application for uniformity.

Each type of machine is designed to handle specific containers, from jars to cans, ensuring flexibility in production lines.

What Are the Standard Food Labeling Regulations?

Compliance with food labeling regulations is critical for food producers, as these laws ensure that consumers receive accurate product information. Key regulations include:

- Ingredient List: Must be clear and list all ingredients in descending order by weight.

- Nutritional Information: Requires detailed nutritional content, including calories, fats, sugars, and more.

- Allergen Warnings: Food labels must clearly identify any potential allergens in the product.

These rules ensure consumers are informed, making it essential that the chosen labeling machine can handle complex labeling tasks.

What Are the 4 Types of Labelling?

In the food industry, there are four main types of labeling:

- Brand Labeling: Promotes brand identity and is often used on packaging to distinguish products in the market.

- Grade Labeling: Provides information about the quality or standard of the product (e.g., organic, non-GMO).

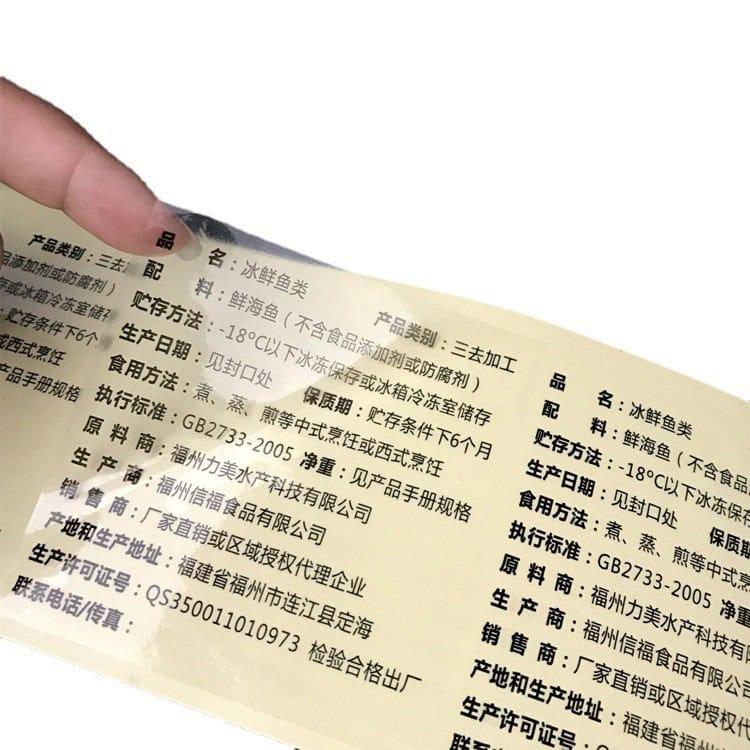

- Descriptive Labeling: Offers detailed information about the product, such as its ingredients and usage instructions.

- Informative Labeling: Includes critical product information like expiration dates, storage conditions, and nutritional values.

What Are the FDA Requirements for Labels?

The U.S. Food and Drug Administration (FDA) requires that food labels provide specific information to ensure consumer safety and product transparency. Key requirements include:

- Statement of Identity: The name of the product must be clear and not misleading.

- Net Quantity: The amount of product in the package must be listed.

- Nutrition Facts: A standardized format for providing nutritional information is mandatory.

- Manufacturer Information: The name and address of the producer must be included.

These FDA regulations guarantee that food labels help consumers make informed choices.

What Is Food Label Compliance?

Food label compliance refers to ensuring that your product’s labels meet the required legal standards. This involves:

- Accurate Information: Labeling must be truthful and not misleading.

- Correct Format: The label design, layout, and language must comply with industry standards.

- Updated Information: Labels must be regularly reviewed and updated to reflect any changes in ingredients or laws.

Non-compliance can lead to severe penalties, making it essential to invest in high-precision labeling machines.

What Are the Different Types of Label Printing Equipment?

Label printing equipment plays a vital role in producing high-quality food labels. The main types of equipment include:

- Digital Label Printers: Ideal for small batches and customized labels. These printers offer fast, high-quality printing.

- Flexographic Printers: Suitable for large production runs, flexographic printers offer a fast and cost-effective solution.

- Thermal Printers: These use heat to transfer ink onto labels and are particularly efficient for short-run printing.

Choosing the right equipment ensures cost-efficiency and high-quality label production.

What Are the 3 Categories of Labeling?

Labeling can be broken into three primary categories:

- Primary Packaging Labels: These are the labels that consumers see on individual products.

- Secondary Packaging Labels: Used on the outer cartons or packaging that contain multiple units of a product.

- Tertiary Packaging Labels: Often used in logistics, these labels contain information for warehouse tracking and distribution.

Each category serves a unique purpose and requires specialized labeling equipment for maximum efficiency.

What Equipment Is Used for Labeling?

Labeling equipment varies depending on the production scale and product type. Common equipment includes:

- Semi-Automatic Labeling Machines: Ideal for smaller operations, these machines require manual feeding but automate the label application process.

- Fully Automatic Labeling Machines: Perfect for large-scale production, these machines handle everything from feeding to applying labels.

- Wrap Around Labeling Machines: Used for labeling bottles and cylindrical items, applying labels smoothly around the product.

Selecting the right machine depends on the scale of your operations and the packaging style used.

What Are the Different Labeling Methods?

There are several methods used to apply labels to products in the food industry:

- Pressure-Sensitive Labeling: The most common method, using adhesive-backed labels that stick when pressure is applied.

- Shrink Sleeve Labeling: Labels are printed on a shrinkable material that wraps tightly around the product when heat is applied.

- In-Mold Labeling: The label is integrated into the packaging during the molding process, offering high durability.

Each method offers unique benefits, such as flexibility, durability, or cost-efficiency.

How Do I Choose a Label Printer?

When selecting a label printer, consider the following factors:

- Label Volume: How many labels do you need to print each day?

- Label Complexity: Do your labels require color, detailed designs, or just basic information?

- Cost Efficiency: Compare the cost per label between different types of printers.

For large food manufacturing operations, investing in high-speed, high-capacity printers can increase efficiency and reduce costs.

What Is the Difference Between a Label Printer and a Label Maker?

A label printer is a machine designed to print high volumes of labels, often in complex designs and formats. It’s perfect for large operations that require high-quality labels.

A label maker, on the other hand, is a simpler device used for creating basic labels quickly. It’s often used for small tasks like labeling office supplies or storage containers.

For the food industry, a label printer is the more suitable option due to the higher volume and complexity of labels required.

What Is the Difference Between Thermal and Non-Thermal Label Makers?

Thermal label makers use heat to transfer ink onto labels, making them fast and efficient for short runs. They are particularly useful for labeling products with simple designs or barcodes.

Non-thermal label makers use traditional printing methods, offering more flexibility in terms of design and color. They are better suited for large-scale, complex label printing tasks.

Choosing between the two depends on your labeling needs—thermal printers are cost-effective for basic labeling, while non-thermal printers provide higher quality for detailed labels.

Conclusion

Choosing the right labeling machine for the food industry involves understanding regulations, labeling methods, and equipment options. By selecting the appropriate machine, businesses can ensure compliance, improve efficiency, and maintain product quality.