The proper labeling of bottles is a crucial aspect for many industries, from beverages to pharmaceuticals. However, traditional manual methods often fall short when it comes to efficiency, precision, and scalability.

Bottle labeling machines enhance production with their user-friendly design, low maintenance, energy efficiency, and ability to increase productivity. They simplify operations, reduce costs, and are essential for efficient bottling lines.

Below, we delve deeper into the specific benefits and features of bottle labeling machines to illustrate why they are an indispensable tool for modern businesses.

Advantages of Labeling Machines

User-Friendliness

Bottle labeling machines are designed with simplicity in mind, making them easy for operators to use without requiring extensive training. These machines often feature touchscreens or intuitive control panels, allowing operators to adjust settings with minimal effort. By simplifying the labeling process, workers can focus more on the overall production workflow, which ultimately enhances their experience and boosts productivity.

Low Maintenance

Maintenance is an ongoing concern for any production line, but bottle labeling machines are built to minimize downtime. These machines require less frequent maintenance due to their durable construction, which reduces the likelihood of breakdowns and the need for constant repairs. By lowering maintenance requirements, companies can extend the machine’s lifespan and significantly reduce operating costs over time.

Power Efficiency

Power consumption is an important factor for businesses looking to reduce costs and environmental impact. Bottle labeling machines are typically designed to be energy-efficient, consuming less electricity while still maintaining high performance. This not only benefits the company by lowering energy bills but also contributes to broader energy conservation efforts, making it a win-win situation.

Increased Productivity

Modern bottle labeling machines are built for speed and efficiency. They feature fast changeover times between different label sizes and product shapes, which helps minimize production delays. Additionally, low rejection rates ensure that fewer products are wasted due to labeling errors, maximizing the overall output of the production line.

Key Features of Labeling Machines

Automatic Label Length Detection

One of the standout features of modern labeling machines is automatic label length detection, which eliminates the need for manual input of label sizes. This feature allows for more efficient operation, as the machine can adjust itself to handle different label sizes, reducing the likelihood of human error and speeding up the labeling process.

Label Placing Systems

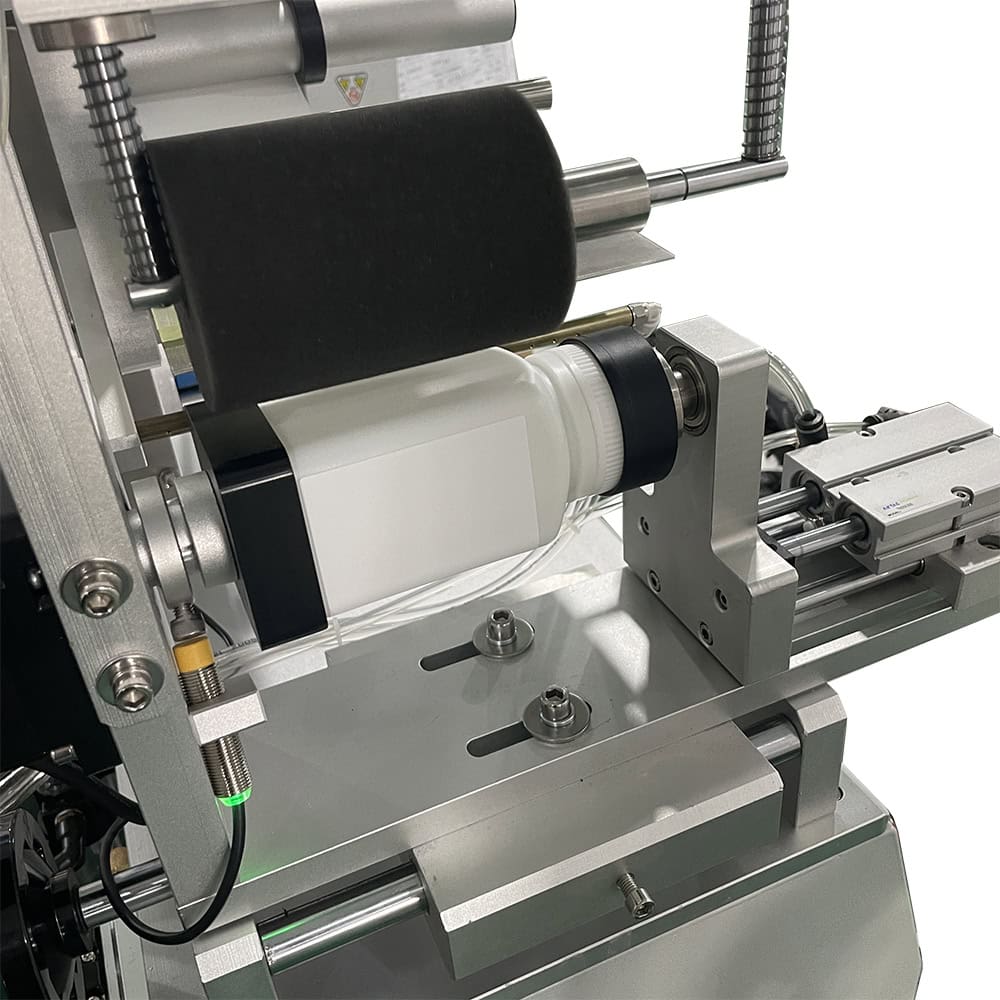

Precision is key in labeling, and advanced label placing systems ensure that labels are applied accurately. These systems are designed to maintain proper label alignment, reducing the need for frequent adjustments by operators. This results in consistent, high-quality labeling across all products.

No Product-No Label System

To prevent wasted materials, bottle labeling machines are equipped with a “No Product-No Label” system. This feature stops the machine from applying labels when there are no bottles present, ensuring that no labels are wasted unnecessarily. This saves both materials and costs, contributing to the overall efficiency of the production line.

Bottle Compatibility

Bottle labeling machines are highly versatile, capable of working with different bottle sizes without requiring additional parts. Built-in bottle separators allow the machine to handle various shapes and sizes, making it suitable for a wide range of applications. This flexibility reduces the need for specialized equipment, further lowering operating costs.

Materials and Build

The durability of labeling machines is a major advantage. Most machines are constructed from stainless steel, which provides both strength and resistance to wear and tear. This robust build ensures that the machines can withstand the demands of high-volume production while maintaining long-term functionality.

Safety Features

Safety is a top priority in any manufacturing environment. Labeling machines are designed with operator safety in mind, featuring enclosed wiring and other protective elements to minimize the risk of injury. These safety features not only protect workers but also ensure compliance with regulatory standards, reducing liability for the company.

Types of Machines and Applications

Bottle labeling machines come in various models designed to meet different industry needs. These include:

- Self-Adhesive Sticker Labelers: These machines are ideal for round bottles, cartons, and containers.

- Shrink Sleeve Label Applicators: Used for applying shrink sleeves to bottles and other containers.

- Hologram Label Applicators: Suitable for adding anti-counterfeiting holograms, ensuring product authenticity.

- High-Speed Labeling Machines: Designed for large-scale production lines, offering faster labeling speeds and multi-label application capabilities.

Industries and Products

Labeling machines are widely used across various industries, including pharmaceuticals, cosmetics, food and beverage, automotive, and Fast-Moving Consumer Goods (FMCG). Specific products that benefit from these machines include shampoo bottles, hair oil containers, liquor bottles, syrups, and more. The versatility and adaptability of labeling machines make them a perfect fit for different products and industries.

Automation and Efficiency

Integration with Production Lines

Bottle labeling machines can easily be integrated into existing production lines, often working in tandem with capping or packaging machines. This seamless integration helps streamline operations, reducing manual labor and improving overall production efficiency.

Cost-Effectiveness

While the initial investment in bottle labeling machines can be significant, the long-term savings are substantial. These machines reduce labor costs, minimize waste, and increase production speed, which can offset the upfront expense over time. Additionally, the precision and automation provided by labeling machines lead to fewer errors, further reducing costs associated with product rework or rejection.

Safety and Reliability

Incorporating safety features and ensuring reliable operation is a standard practice for modern labeling machines. These features help reduce workplace accidents and injuries while maintaining high operational reliability, ensuring that production runs smoothly without frequent interruptions.

Labeling Options

Labeling machines offer flexibility in terms of the types of labels they can apply. Options include wrap-around labels, front-and-back labels, barcodes, and QR codes, among others. This versatility allows businesses to present their products in the best possible light while ensuring compliance with industry regulations regarding product labeling.

Customization and Future-Proofing

Another key benefit of bottle labeling machines is the ability to customize them according to specific product sizes and labeling requirements. Machines can be easily modified or upgraded to accommodate future product lines, making them a long-term investment for businesses that plan to expand their operations.

Conclusion

In summary, bottle labeling machines offer a range of additional benefits that go beyond mere label application. From user-friendliness and low maintenance to advanced technology and energy efficiency, these machines play a critical role in streamlining production processes and reducing costs. Investing in a bottle labeling machine ensures higher productivity, reduced waste, and greater flexibility, making it a valuable asset for any industry.