If you’ve found your way here, it’s likely because you’re in search of a simple yet effective machine to securely cap your bottles. The good news is, you’re in the right place. Whether your business requires a solution for high-volume production or just occasional use, understanding the different types of capping machines available and their respective benefits is essential to making an informed decision.

The tool you’re looking for is called a capping machine—a mechanical device specifically designed to apply caps to bottles of varying sizes. These machines come in both fully automatic and semi-automatic models, catering to different scales of production. Choosing the right one depends largely on your specific needs, such as production volume and budget.

Read on as we guide you through the key considerations when selecting the perfect capping machine for your business.

What is a Capping Machine?

A capping machine is an essential piece of equipment in various industries, including food and beverage, pharmaceuticals, and cosmetics, where it ensures that caps are applied securely and consistently. These machines are vital for maintaining the integrity of products by preventing leaks and contamination.

One of the primary advantages of using a capping machine is that it eliminates the physical strain associated with manual capping. Repeatedly tightening caps by hand can lead to injuries such as repetitive strain injury (RSI), making it unsustainable for long-term operations. By using a capping machine, businesses can not only increase efficiency but also safeguard the health of their workers.

Capping machines vary in design and operation. Some are fully automated, requiring minimal human intervention, while others are semi-automatic, allowing for manual placement of bottles and caps before the machine performs the capping process. Regardless of the type, a capping machine is an invaluable tool that enhances both speed and accuracy in production.

Types of Capping Machines

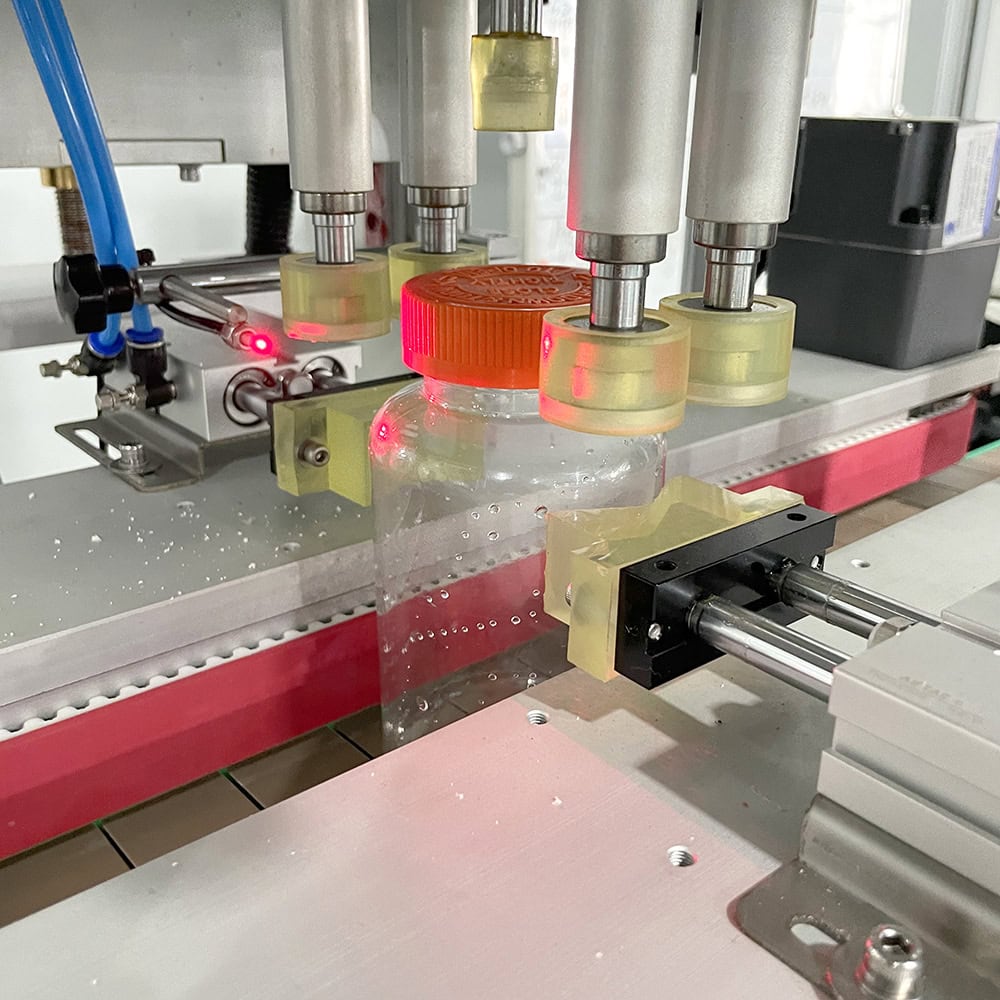

Automatic Bottle Capping Machine

The Automatic Bottle Capping Machine is designed for businesses with high production volumes. It automates the entire capping process, from placing caps onto bottles to securing them tightly. This type of machine is ideal for businesses that require high-speed, consistent results. With features like cap feeders and conveyors, automatic capping machines streamline the entire bottling process, reducing the need for manual labor.

For large-scale operations, an automatic capping machine is the best option. It ensures that every bottle is capped perfectly, significantly reducing the chances of defects or inconsistencies in the final product.

Semi-Automatic Multifunction Capping Machine

A Semi-Automatic Multifunction Capping Machine offers a middle ground between full automation and manual operation. These machines require the operator to manually place the bottle and cap before the machine takes over the capping process. They are ideal for small to medium-sized businesses where flexibility and manual control are important.

These machines are more affordable than fully automatic models and are versatile enough to handle various bottle sizes and cap types. They are particularly useful for businesses that need to switch between different product lines frequently.

What is the Size of Your Bottle Cap?

When selecting a capping machine, one of the most important factors to consider is the size of your bottle cap. Different machines have different capabilities, and not all are equipped to handle every size of cap. Therefore, providing the exact size of your bottle cap when requesting a quote from a manufacturer is crucial.

Fortunately, most capping machines are designed to be versatile. For example, LabeMachine Inc. offers machines that can accommodate caps ranging from 15 to 65mm in diameter and bottles up to 300mm in height. This range is sufficient for most standard bottle sizes, ensuring compatibility and reducing the need for costly adjustments.

What is the Capping Speed?

The speed at which a capping machine operates can significantly impact your overall production capacity. Capping speed is typically measured in terms of the number of bottles capped per minute or hour. Understanding your production needs will help you choose the right machine for your business.

For businesses with high production demands, a fully automatic capping machine is the best choice. These machines can cap thousands of bottles per hour, making them ideal for large-scale operations. On the other hand, if your production needs are lower, a semi-automatic or benchtop machine may be sufficient. These machines offer a good balance between speed and affordability, making them suitable for smaller businesses.

Consider the Price

Price is a key consideration when choosing a capping machine. The cost can vary significantly based on the machine’s features, level of automation, and manufacturer.

Fully automatic capping machines are generally more expensive due to their advanced capabilities and the reduced need for manual labor. However, the investment is often justified for businesses that require high efficiency and consistency in their production processes.

For smaller businesses or those with limited budgets, semi-automatic or benchtop capping machines offer a cost-effective solution. These machines require more manual input but still provide significant time and labor savings compared to manual capping.

If you’re looking for specific pricing information, it’s best to contact the manufacturer directly with your requirements. This will allow you to get a detailed quote tailored to your needs and budget.

Is the Equipment Easy to Operate?

Ease of operation is another important factor to consider, especially if you’re new to using capping machines. Most manufacturers, including LabeMachine Inc., ensure that their machines are pre-adjusted for immediate use, meaning they’re ready to go as soon as they arrive at your facility.

Typically, you only need to connect the machine to the power and air supply, and it’s ready for operation. The user interface is designed to be intuitive, making it easy to learn and operate even for those with minimal technical experience. Semi-automatic benchtop capping machines are particularly user-friendly; you simply place the bottle and cap in position, press a foot switch, and the machine completes the capping process.

Does the Power Supply Match?

Ensuring that the power supply of your capping machine matches your country’s voltage standards is essential to avoid damage and ensure efficient operation. Different countries have different voltage requirements, so it’s important to check this before making a purchase.

At LabeMachine Inc., the default setting for our machines is 220V/50HZ, but we can adjust the voltage to match your country’s specifications before shipping. This ensures that when your machine arrives, it’s ready to plug in and use immediately, without the need for additional adjustments.

Conclusion

Selecting the right capping machine for your business involves careful consideration of factors like cap size, production speed, price, and ease of operation. By understanding these aspects and evaluating your specific needs, you can choose a machine that will enhance your production efficiency and support your business growth. If you need further guidance or a detailed quote, feel free to contact us—we’re here to help you find the perfect capping solution.