Maintaining a labeling machine is crucial for ensuring its optimal performance and extending its lifespan. Neglecting routine cleaning and maintenance can lead to costly repairs, machine downtime, and a decrease in labeling accuracy, all of which can affect your production line’s efficiency.

To clean a labeling machine, start by disconnecting the power, gather appropriate cleaning tools, and focus on key areas like the label feed system, rollers, and conveyor belt. Regularly lubricate moving parts, inspect for wear, and perform calibration checks to ensure accuracy. Replace worn components promptly and troubleshoot common issues to prevent downtime. Regular maintenance ensures optimal performance and extends the machine’s lifespan.

Keep reading to discover practical tips for cleaning, maintaining, and troubleshooting your labeling machine to ensure it runs smoothly and efficiently.

Preparing for Cleaning

Before diving into the cleaning process, it’s important to take a few preparatory steps to ensure safety and effectiveness.

Safety Precautions

Safety should always come first. Before starting any maintenance work, disconnect the machine from its power source to prevent accidental operation. Additionally, wear protective gloves and goggles to avoid injury from any sharp parts or cleaning chemicals. Refer to your machine’s manual for specific safety guidelines, as different models may have unique requirements.

Tools and Materials Needed

Having the right tools and materials on hand is key to an effective cleaning process. You will need soft, lint-free cloths, brushes of various sizes, mild cleaning solutions, and lubricants specifically recommended by the machine’s manufacturer. It’s also helpful to have a small vacuum cleaner to remove dust and debris from hard-to-reach areas.

Cleaning the Labeling Machine

Regular cleaning is essential to maintaining the efficiency and accuracy of your labeling machine. Here’s how to clean the key components.

Step-by-Step Cleaning Process

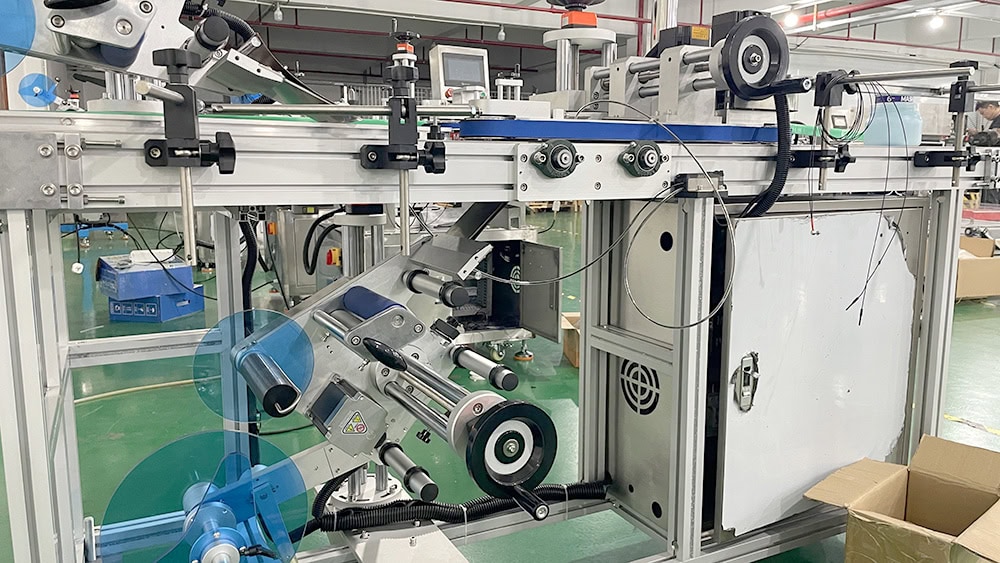

- Cleaning the Label Feed System: Start by inspecting the label feed system. Over time, adhesive residues can accumulate on the rollers and guides, leading to misfeeds or jams. Use a soft cloth moistened with a mild cleaning solution to wipe down these areas, ensuring that no sticky substances remain.

- Cleaning Rollers and Sensors: Rollers and sensors are critical for accurate labeling. Dirt and debris on these parts can cause misalignment or misreads. Carefully clean the rollers with a cloth, and use a soft brush to gently clean the sensors, being mindful not to scratch or damage them.

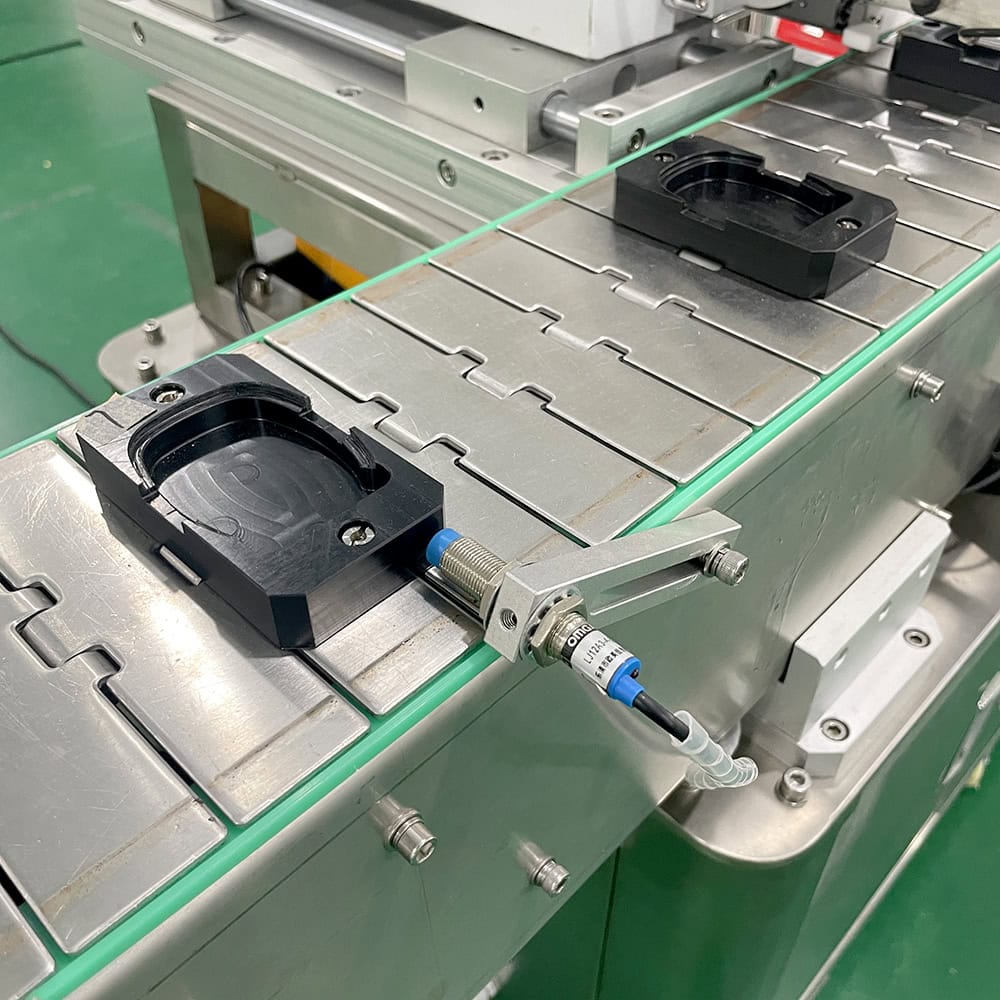

- Conveyor Belt Maintenance: The conveyor belt is another area prone to dirt buildup. Regularly wipe it down to remove dust, and inspect it for any signs of wear or damage that could affect the machine’s operation.

Frequency of Cleaning

The frequency of cleaning depends on the machine’s usage. For high-volume operations, a daily cleaning routine is recommended. For machines used less frequently, cleaning after every few production runs should suffice. Always follow the manufacturer’s recommendations for cleaning intervals to ensure optimal performance.

Routine Maintenance Tasks

In addition to cleaning, regular maintenance tasks are necessary to keep your labeling machine running smoothly.

Lubrication of Moving Parts

Lubricating the moving parts of your labeling machine is crucial for preventing wear and tear. Focus on the gears, bearings, and any sliding components. Use a lubricant that is specifically designed for your machine model, as using the wrong type can cause damage. Apply the lubricant sparingly and wipe away any excess to avoid attracting dust and debris.

Inspection of Components

Regularly inspecting key components such as belts, gears, and electrical connections can help you identify potential issues before they become major problems. Look for signs of wear, cracks, or loose connections. Replace any worn parts immediately to avoid unplanned downtime.

Calibration Checks

To maintain labeling accuracy, periodic calibration is essential. Calibration ensures that the labels are applied precisely at the correct position on each product. If your machine begins to show signs of misalignment, it’s time to recalibrate. For more detailed guidance, refer to a labeling machine maintenance guide.

Replacing Worn Parts

It’s important to replace these components promptly to keep the machine in good working order. Common parts that may need replacement include belts, rollers, and sensors. Always use genuine replacement parts recommended by the automatic labeling machine manufacturers to ensure compatibility and longevity.

Troubleshooting Common Maintenance Issues

Despite your best efforts, issues can still arise. Knowing how to troubleshoot these problems can save time and prevent extended downtime.

Identifying Symptoms of Poor Maintenance

Common symptoms of inadequate maintenance include unusual noises, inconsistent label placement, and frequent machine stoppages. These issues often indicate that a component needs cleaning, lubrication, or replacement.

Quick Fixes

For minor issues, such as label misfeeds or slight misalignment, quick adjustments can often resolve the problem. Check the label feed path for obstructions, realign sensors, or adjust the tension on the conveyor belt.

When to Call a Professional

Some issues are too complex to handle on your own. If you encounter persistent problems that don’t respond to standard troubleshooting, it’s best to call in a professional technician. Regularly scheduled professional maintenance can also help catch potential problems early.

Conclusion

Regular cleaning and maintenance of your labeling machine are essential for ensuring its long-term performance and reliability. By following the steps outlined in this guide, you can minimize downtime, reduce repair costs, and keep your production line running smoothly. Incorporate these practices into your routine to avoid unexpected breakdowns and maintain the accuracy and efficiency of your labeling operations.