The demand for China labeling machines has skyrocketed globally, as industries recognize their cost-effectiveness and reliability. However, the true value of these machines is only realized when they are operated efficiently and maintained properly. Neglecting these aspects can lead to frequent breakdowns, reduced productivity, and increased costs.

Maximizing efficiency and longevity in operating China labeling machines involves implementing best practices in both operation and maintenance. By understanding the core features of your labeling machine and following systematic maintenance strategies, you can significantly enhance its performance and lifespan.

To ensure that your labeling machine delivers consistent results and stands the test of time, it’s crucial to adopt a proactive approach. This includes not only optimizing daily operations but also focusing on regular maintenance and timely interventions.

Understanding the Core Features of China Labeling Machines

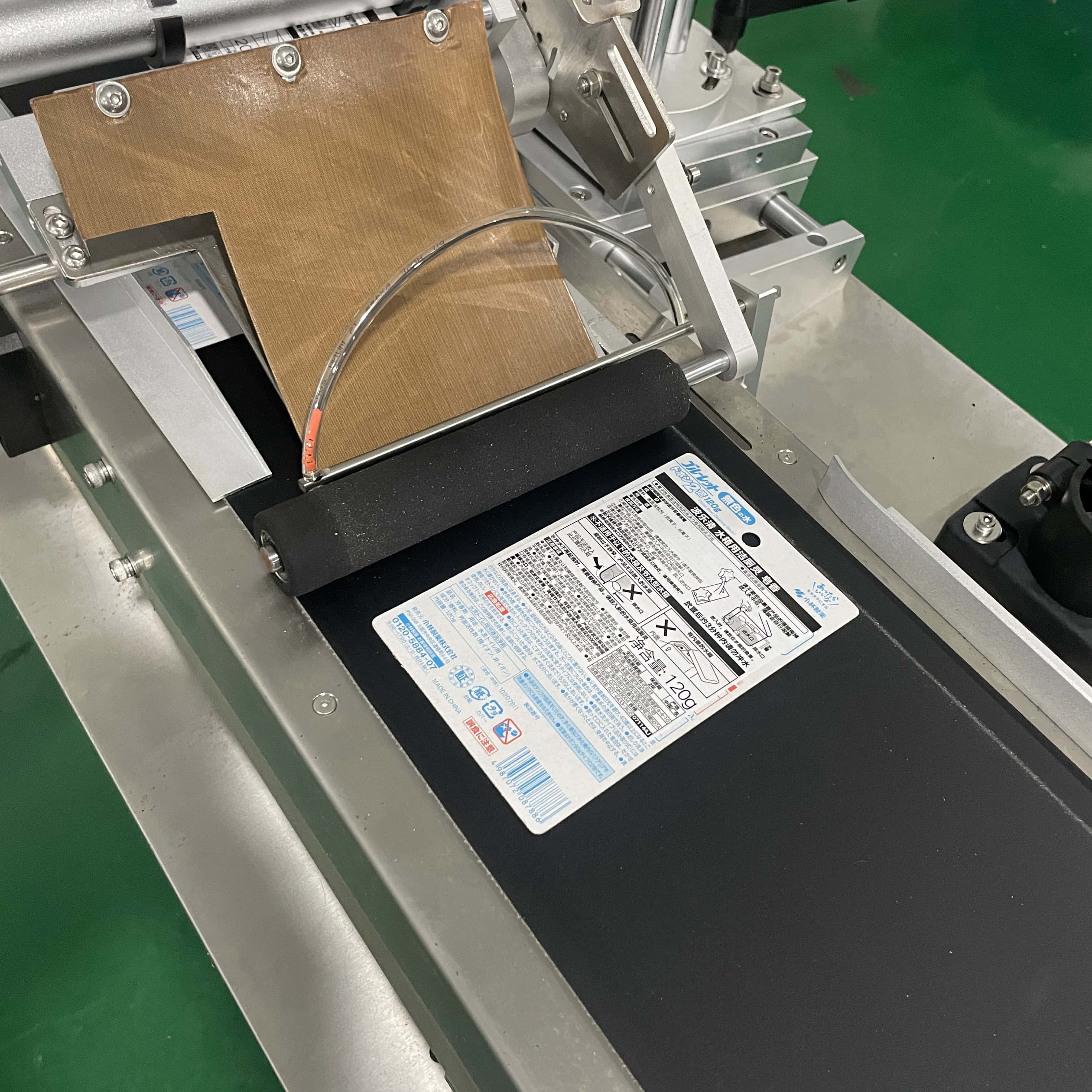

China labeling machines, such as the china label pasting machine and the china machine label applicator, are designed to cater to a wide range of industrial needs. These machines come with various features that make them versatile and efficient. Understanding these core features is the first step towards optimizing their use.

For instance, china manual labeling machines are ideal for small to medium-sized operations where flexibility and ease of use are paramount. These machines typically feature adjustable settings that allow for quick changes between different labeling tasks. On the other hand, automated machines offer higher throughput and are better suited for large-scale operations where consistency and speed are critical.

When selecting a labeling machine, consider the specific needs of your operation. Factors such as the type of products being labeled, the required speed, and the precision needed should guide your choice. By aligning the machine’s features with your operational needs, you can ensure that it performs optimally under varying conditions.

Best Practices for Operating China Labeling Machines

Operating a China labeling machine efficiently requires attention to detail and adherence to best practices. One of the most important aspects is ensuring that the machine is set up correctly before starting any labeling tasks. This includes calibrating the machine properly, adjusting the settings according to the product specifications, and conducting a test run to identify any potential issues.

Common operational mistakes include incorrect label placement, improper product alignment, and failure to adjust machine settings when switching between different products. These mistakes can lead to downtime and increased wastage. To avoid these issues, it is essential to train operators thoroughly and to implement standardized procedures for machine operation.

Incorporating advanced features like automated label detection or utilizing visual inspection systems can further enhance operational efficiency. These technologies help to minimize errors and ensure consistent label application, which is crucial for maintaining product quality and compliance with industry standards.

Maintenance Strategies to Extend the Lifespan of Labeling Machines

Maintenance is the cornerstone of ensuring the long-term performance of your labeling machine. A well-maintained machine not only operates more efficiently but also has a longer lifespan, reducing the need for costly replacements. China labeling machine factories often provide detailed maintenance guidelines that should be followed rigorously.

Routine maintenance includes cleaning the machine regularly, checking for wear and tear on critical components, and replacing parts as needed. Lubrication of moving parts is also crucial to prevent mechanical failures. Moreover, conducting periodic inspections and servicing by qualified technicians can help identify potential issues before they become major problems.

Preventive maintenance is another strategy that can significantly reduce downtime. This involves scheduling regular checks and servicing based on the machine’s usage patterns and operating conditions. By addressing minor issues early, you can prevent them from escalating into more serious problems that could disrupt your production schedule.

Case Studies: Real-World Applications and Results

To illustrate the impact of effective operation and maintenance, consider the case of a manufacturing plant that implemented a comprehensive maintenance plan for their china label pasting machine. The plant reported a 25% increase in machine uptime and a significant reduction in labeling errors after optimizing their maintenance procedures.

Another example is a pharmaceutical company that upgraded to a china machine label applicator with automated features. By doing so, they not only improved labeling accuracy but also reduced the time needed for label changes, leading to a 30% boost in productivity.

These case studies highlight the tangible benefits that can be achieved through proper operation and maintenance of China labeling machines. By following the best practices outlined in this article, businesses can enhance their operational efficiency and ensure that their labeling machines continue to perform at their best.

Conclusion

In conclusion, maximizing the efficiency and longevity of your China labeling machine requires a balanced approach that combines proper operation with regular maintenance. By understanding the core features of your machine, adhering to best practices in operation, and implementing a robust maintenance plan, you can achieve optimal performance and extend the life of your equipment. Implementing these strategies will not only improve productivity but also reduce costs associated with machine downtime and repairs.