The best price label machine isn’t necessarily the cheapest one. Instead, it’s the machine that fits your specific requirements, offers reliable performance, and comes with solid after-sales support. In this article, I’ll walk you through what you need to know to make an informed decision.

Now that you’re here, I’ll guide you through the essential factors that will help you identify the best price label machine for your needs.

What Is a Label Machine?

A label machine is an essential piece of equipment in any production line that requires labeling. It automates the process of applying labels to products, packaging, or containers, thereby increasing efficiency and reducing the chance of errors. Label machines are used across various industries, including food and beverage, pharmaceuticals, cosmetics, and manufacturing. The primary function of a label machine is to apply labels quickly and accurately, ensuring that each product is properly branded and complies with industry regulations.

Label machines can be either semi-automatic or fully automatic, depending on the production needs. Semi-automatic machines require some manual intervention, whereas fully automatic machines are capable of running without any human input once they’re set up. This automation reduces labor costs and speeds up production, making them a worthwhile investment for businesses looking to scale up their operations.

Types of Label Machines

Label machines come in various types, each designed for specific applications. Understanding the differences between these types is crucial when selecting the right machine for your production needs.

Wire Label Machines: These are specialized machines used for labeling cables and wires. They ensure that each wire is properly identified, which is essential in industries like telecommunications, electrical installations, and automotive manufacturing. Wire label machines are designed to handle the unique challenges of labeling round or cylindrical objects, ensuring that the labels adhere properly and are easy to read.

Flat Surface Label Machines: These machines are designed for labeling flat surfaces, such as boxes, pouches, or flat bottles. They are commonly used in industries that require large-scale labeling of packaging materials. Flat surface label machines can be either manual, semi-automatic, or fully automatic, and they are known for their precision and speed.

Bottle Label Machines: As the name suggests, these machines are used for labeling bottles. They are widely used in the beverage, pharmaceutical, and cosmetics industries. Bottle label machines can handle various shapes and sizes of bottles, from small vials to large containers. Depending on the complexity of the label and the bottle’s shape, these machines can be equipped with additional features, such as rotating platforms or multi-label capabilities.

The price of a label machine can vary significantly depending on the type. For example, a wire label machine might be less expensive than a fully automated bottle label machine, but it all depends on the specific features and capabilities of the machine. The key is to choose a machine that meets your production requirements without unnecessary extras that inflate the cost.

What Makes a Label Machine’s Price the Best?

Finding the best price for a label machine is about more than just finding the lowest price tag. The most affordable label machine is the one that perfectly aligns with your specific production needs. Here’s what to consider:

First, the machine should be reliable. Nothing is more costly than frequent downtime due to machine failures. A machine that is well-suited to your product type and production volume will operate smoothly, reducing the chances of unexpected breakdowns. Furthermore, the best price includes not just the initial cost of the machine but also the long-term costs associated with maintenance, repairs, and operational efficiency.

Second, after-sales support is critical. A machine with a lower upfront cost but poor support can end up costing more in the long run. Consider the availability of spare parts, the responsiveness of customer service, and the quality of the warranty. All these factors contribute to the overall value of the machine.

Finally, consider how well the machine integrates with your existing production line. A machine that requires extensive modifications to your current setup may not be the best choice, even if it has a low price. The best price is achieved when the machine seamlessly fits into your operations, minimizing disruptions and maximizing productivity.

Key Components That Affect the Price of a Label Machine

Several key components in a label machine significantly impact its price. Understanding these components can help you make an informed decision when comparing different models.

Labeling Mechanism: This is one of the most crucial components of any label machine. The labeling mechanism must be customized to handle your specific product, whether it’s a flat surface, a bottle, or a wire. Customization often adds to the cost, but it ensures that the labels are applied accurately and efficiently. A poorly designed labeling mechanism can lead to mislabeling, which can cause costly production delays and product recalls.

PLC and Electrical Components: The quality of the PLC (Programmable Logic Controller) and other electrical components can greatly influence the machine’s price. High-quality electrical components ensure that the machine operates reliably over time, even in demanding production environments. While it may be tempting to choose a machine with cheaper components, this can lead to more frequent breakdowns and higher maintenance costs over time. In the long run, investing in a machine with durable, high-quality components is more cost-effective.

Label Sensor: A good label sensor is essential for ensuring that the labels are applied correctly. A high-quality sensor can detect labels with high accuracy, even if they are transparent or reflective. On the other hand, a poor-quality sensor might fail to detect labels accurately, leading to misapplication and wasted materials. Investing in a machine with a reliable label sensor is crucial for maintaining production efficiency and reducing waste.

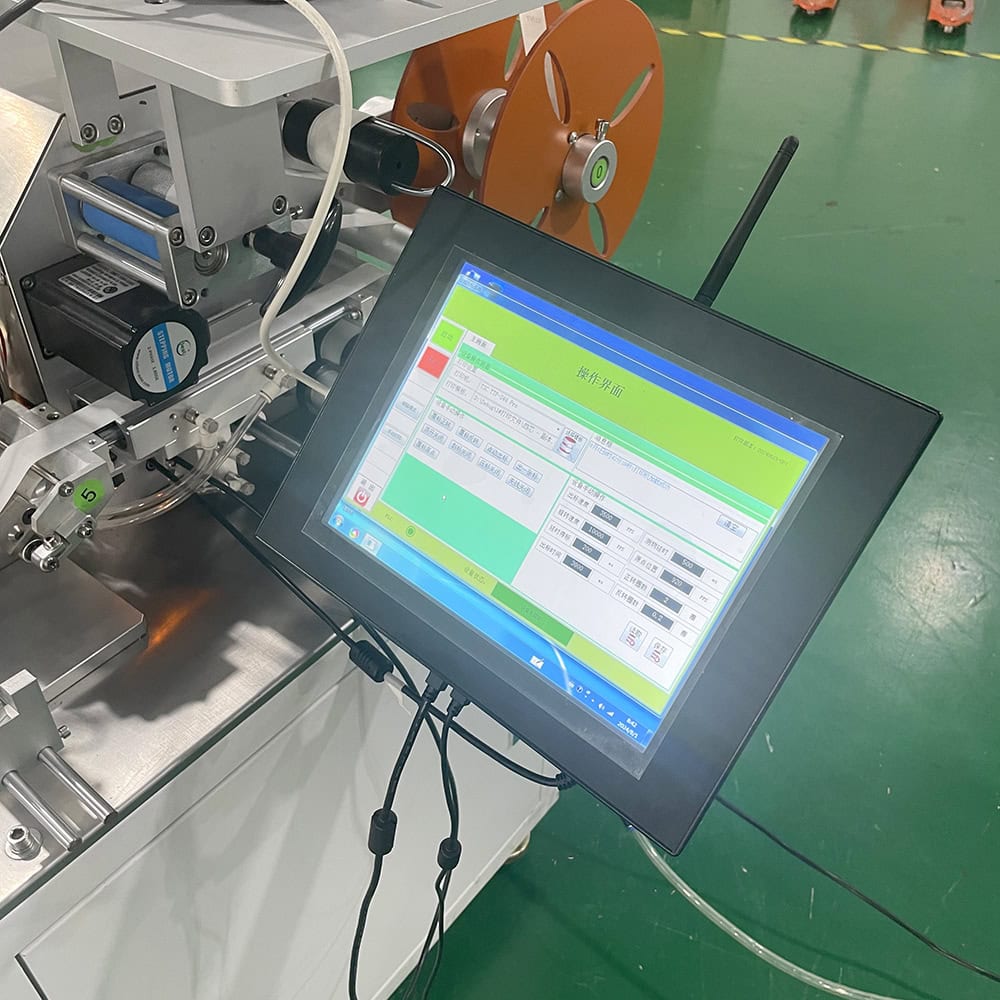

Human-Machine Interface (HMI): The HMI is the interface through which the operator controls the machine. A user-friendly HMI can greatly enhance the ease of use and efficiency of the machine. A machine with a well-designed HMI may cost more initially, but it can save time and reduce errors during operation, making it a worthwhile investment.

How to Find the Best Price Label Machine?

When it comes to finding the best price for a label machine, the most important factor is identifying a reputable manufacturer. As someone who has been in the automation equipment industry for over 20 years, I can tell you that the source of the machine plays a critical role in determining both the price and the quality of the product.

LabeMachine, for instance, is a specialized manufacturer of label machines, offering not just competitive prices but also reliable after-sales service and technical support. This combination of affordability and quality is what makes us stand out in the industry. By purchasing directly from a manufacturer like LabeMachine, you can eliminate the middleman markup, ensuring that you get the best value for your money.

Moreover, working with a dedicated manufacturer allows you to customize the machine to fit your exact production needs. This level of customization, combined with direct support from the manufacturer, ensures that the machine will perform optimally, reducing the total cost of ownership over time.

In summary, finding the best price label machine is about more than just comparing price tags. It’s about finding a machine that offers the right balance of cost, quality, and support. By considering all these factors, you can ensure that you’re making a smart investment that will pay off in the long run.

Conclusion

Finding the best price for a label machine isn’t about choosing the cheapest option; it’s about finding the right fit for your production needs. By understanding the different types of label machines, what affects their prices, and the importance of a reliable manufacturer, you can make an informed decision that ensures long-term success for your business. Remember, the best investment is one that balances cost with quality and ongoing support.