When you read this article, it means you are looking for information related to labeling machines. Otherwise you would not have viewed such a specialized article. Let me guess, you are looking for labeling machines? You want to buy labeling machines?

Well, this article is for you, keep reading and I hope it will be useful for you.

When buying a label machine, consider the type of machine, key features like speed and precision, and your specific business needs. Assess the machine’s compatibility with your products and labels, and factor in budget and long-term costs. Choosing the right machine can enhance efficiency and product quality.

Choosing the right label machine is a critical decision. It’s not just about the price but also the machine’s functionality and compatibility with your products. Let’s delve deeper into the key considerations.

Understanding Different Types of Label Machines

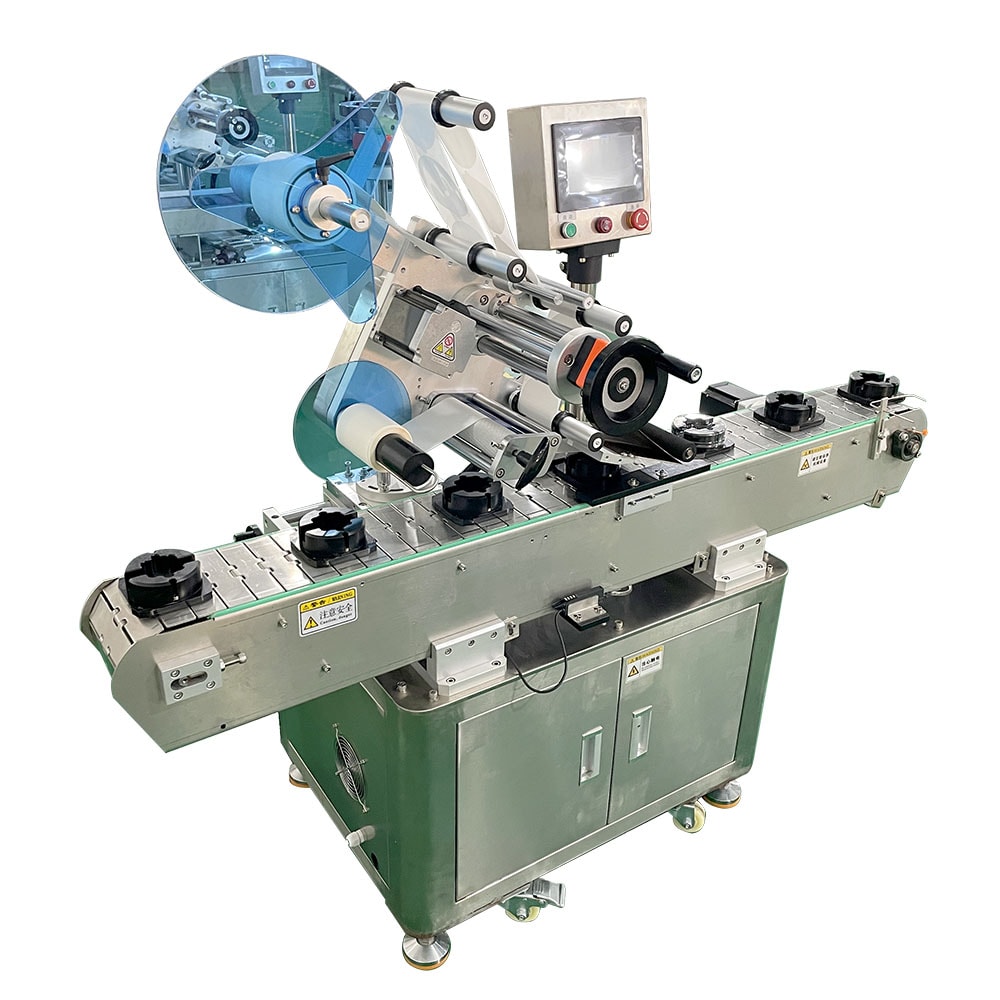

Label machines come in various types, each designed to meet specific needs. The most common categories include automatic, semi-automatic, tabletop, industrial, and specialized machines. Automatic label machines are known for their high speed and precision, making them ideal for large-scale production. These machines can apply labels to products without manual intervention, significantly increasing throughput.

Semi-automatic machines, on the other hand, require some level of human involvement. They are often more affordable than their automatic counterparts and are suitable for businesses with moderate production volumes. Tabletop label machines are compact and versatile, perfect for small businesses or those with limited space. Despite their size, they offer impressive performance and can handle various label types.

Industrial and specialized label machines cater to niche applications. Industrial machines are built for heavy-duty use, capable of operating continuously in demanding environments. Specialized machines are tailored for specific tasks, such as labeling cylindrical or uniquely shaped products. Understanding these types helps in identifying which machine aligns with your operational needs and production scale.

Key Features to Look for in a Label Machine

When evaluating label machines, it’s crucial to consider key features that impact performance and usability. Labeling speed and efficiency are top priorities, especially for high-volume production lines. Machines with adjustable speed settings allow for flexibility, enabling operators to match the machine’s pace with other equipment in the production line.

Precision and accuracy in label placement are also critical. Misaligned labels can lead to product rejection and increased waste. Advanced machines often incorporate technologies like sensors and cameras to ensure precise label application. Additionally, consider the machine’s compatibility with different label types and materials. Some machines are versatile enough to handle paper, plastic, and foil labels, while others may be limited to specific materials.

Ease of use is another important factor. User-friendly interfaces, such as touchscreens and programmable settings, simplify the operation and reduce the likelihood of errors. Machines with quick-change features for different label sizes and shapes can save valuable time during production runs. These features collectively contribute to the machine’s overall efficiency and effectiveness.

Assessing Your Business Needs

Understanding your business’s specific needs is fundamental when choosing a label machine. Start by evaluating your production volume requirements. The number of products you need to label daily or weekly will influence the type of machine you should consider. For high-volume needs, automatic machines are typically the best choice, offering speed and consistency.

Next, consider the size and capacity of the machine. Ensure that the machine can handle the product dimensions and label sizes you use. It’s also essential to think about the variety of products you label. If you produce multiple product lines, a machine with flexible label application capabilities will be more beneficial.

Finally, take into account the product and label specifications. Different products may require specific label materials, adhesives, or application methods. For instance, products exposed to moisture may need waterproof labels, while others may require tamper-evident seals. Assessing these requirements helps in selecting a machine that meets all your production criteria.

Budget Considerations and Pricing

Budget is often a deciding factor when purchasing a label machine. While it’s important to find a machine that fits within your financial constraints, it’s equally crucial to consider the long-term benefits and potential cost savings. Label machines vary widely in price, depending on their type, features, and capabilities.

Automatic machines, while generally more expensive, offer higher efficiency and can reduce labor costs in the long run. Semi-automatic and tabletop label machines are more affordable upfront but may require more manual labor. It’s essential to balance the initial investment with the machine’s long-term benefits, such as increased productivity and reduced waste.

Additionally, consider other associated costs, including maintenance, consumables, and potential upgrades. Regular maintenance ensures the machine operates at peak efficiency and extends its lifespan. Consumables like labels, adhesives, and spare parts should also be factored into the overall cost. By considering all these aspects, you can choose a machine that offers the best value for your investment.

Ease of Use and Operator Training

The ease of use of a label machine significantly impacts its integration into your production line. Machines with intuitive controls and interfaces minimize the learning curve for operators. This is particularly important in environments with frequent staff changes, as it reduces the time and resources needed for training.

User-friendly features, such as touchscreens and programmable memory settings, allow for quick adjustments and fine-tuning. This flexibility is beneficial for companies with diverse product lines, as operators can easily switch between different label configurations. Additionally, machines with clear operational instructions and troubleshooting guides can help prevent common issues and reduce downtime.

Investing in operator training is also essential. Well-trained operators are more likely to use the machine efficiently and troubleshoot minor problems without external assistance. Some suppliers offer training programs or support materials, which can be invaluable in ensuring that your team is proficient in using the equipment. Overall, a user-friendly machine coupled with proper training can enhance productivity and reduce operational costs.

Maintenance and Reliability

Maintenance and reliability are critical considerations when choosing a label machine. Regular maintenance ensures that the machine remains in optimal condition, preventing breakdowns and costly repairs. It’s important to understand the machine’s maintenance requirements and schedule preventive maintenance to avoid unexpected downtime.

The reliability of the machine is equally important. Durable machines with robust construction can withstand the demands of continuous operation. Look for machines made from high-quality materials and components, as these are less likely to wear out or fail over time. A reliable machine not only minimizes maintenance costs but also ensures consistent performance, which is crucial for maintaining production schedules.

Access to spare parts and technical support is another key factor. Machines with readily available parts are easier to repair, reducing downtime. Additionally, having access to technical support from the manufacturer or supplier can be invaluable in addressing any issues that arise. By prioritizing maintenance and reliability, you can ensure the longevity and efficiency of your label machine.

Exploring the Latest Trends in Label Machines

The label machine industry is constantly evolving, with new technologies and innovations emerging regularly. One of the latest trends is the integration of smart technology into label machines. These machines can be connected to a network, allowing for real-time monitoring and control. Smart label machines can also collect data on production metrics, helping businesses optimize their processes and improve efficiency.

Another trend is the increasing use of automation in label machines. Fully automated systems can perform multiple tasks, such as product handling, label application, and quality inspection, without human intervention. This not only speeds up production but also reduces the risk of errors and inconsistencies. Automation also allows for seamless integration with other systems in the production line, further enhancing efficiency.

Environmental considerations are also becoming more prominent. Many manufacturers are now offering eco-friendly label machines that use energy-efficient technologies and sustainable materials. These machines are designed to minimize waste and reduce the environmental impact of the labeling process. As more companies prioritize sustainability, eco-friendly label machines are expected to become increasingly popular.

Finding Reliable Suppliers and Purchasing Channels

Finding a reliable supplier is crucial when purchasing a label machine. A reputable supplier will offer high-quality equipment, transparent pricing, and excellent customer service. When evaluating suppliers, consider their experience in the industry, the range of products they offer, and their reputation among other customers. Reading reviews and testimonials can provide valuable insights into the supplier’s reliability and customer satisfaction.

Online purchasing channels have become increasingly popular, offering convenience and a wide selection of products. Many manufacturers and distributors have online platforms where you can browse and purchase label machines. These platforms often provide detailed product descriptions, specifications, and customer reviews, helping you make an informed decision. However, it’s essential to verify the legitimacy of the seller and ensure they offer secure payment options and warranties.

In addition to online channels, visiting trade shows or manufacturer facilities can provide hands-on experience with different machines. This can be particularly useful for evaluating the build quality, ease of use, and overall functionality of the machines. By thoroughly researching and comparing suppliers and purchasing channels, you can find the best label machine for your needs and ensure a smooth buying process.

Conclusion

Selecting the right label machine is a critical decision that can significantly impact your production efficiency and product quality. By understanding the different types of machines, key features, and your specific business needs, you can make an informed choice. Whether you’re looking for speed, precision, or versatility, there’s a label machine that fits your requirements. Take the time to research and evaluate your options, and don’t hesitate to consult with experts or suppliers for guidance. With the right machine, you can streamline your operations, reduce costs, and enhance your product’s presentation.