The benchmate labeling machine is a class of simple, compact labeling machines. This article will take you through everything you need to know about it. I hope it will be useful for you.

What is a Benchmate Labelling Machine?

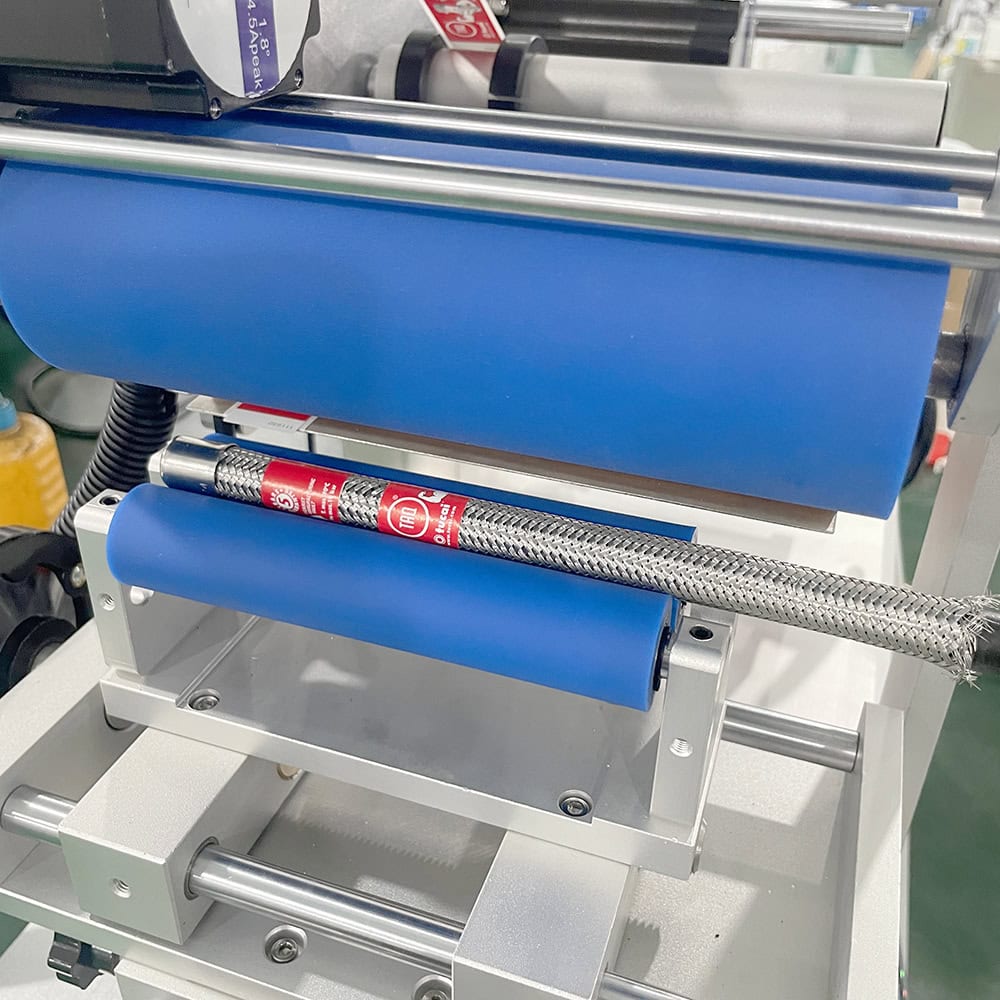

The Benchmate Labelling Machine is a standardized, off-the-shelf labelling solution designed for a wide range of applications. Unlike custom labelling machines, which are tailored to specific products or processes, the Benchmate offers a versatile approach that can accommodate various label types and container sizes. Its compact design makes it ideal for businesses with limited space, while its straightforward operation ensures minimal training is required.

One of the key features of the Benchmate Labelling Machine is its adaptability. It’s capable of handling cylindrical products with diameters ranging from 10mm to 50mm, making it suitable for items like water pipes, small round bottles, and more. This flexibility is particularly beneficial for businesses that deal with multiple product lines, as it allows for quick and easy adjustments without the need for extensive reconfiguration. The Benchmate’s durability and ease of maintenance further enhance its appeal, offering a reliable solution for high-volume production environments.

Applications of Benchmate Labelling Machine

The versatility of the Benchmate Labelling Machine makes it suitable for a wide range of applications, particularly in industries dealing with cylindrical products. It excels in labelling items such as water pipes, small round bottles, tubes, and more. The machine’s adjustable settings allow for precise labelling on various surfaces and materials, ensuring that labels adhere securely and remain legible throughout the product’s lifecycle.

In the food and beverage industry, the Benchmate is often used for labelling bottles and cans, providing essential information such as product names, nutritional facts, and barcodes. Its ability to handle different label sizes and shapes makes it an invaluable asset for companies with diverse product lines. Similarly, in the pharmaceutical industry, the Benchmate ensures that labels are applied accurately and consistently, helping to maintain compliance with regulatory standards. This versatility, combined with its reliability, makes the Benchmate a popular choice across multiple sectors.

Benchmate Labelling Machine Price

When it comes to pricing, the Benchmate Labelling Machine offers a competitive advantage. As a standardized product, it is generally more affordable than custom-built machines. This cost-effectiveness makes it an attractive option for small to medium-sized enterprises looking to optimize their production lines without breaking the bank. The price of a Benchmate Labelling Machine can vary depending on the model and additional features, but it typically falls within a reasonable range that offers excellent value for money.

In addition to the initial purchase price, it’s important to consider the long-term cost savings associated with the Benchmate. Its durable construction and reliable performance mean fewer maintenance issues and lower operating costs over time. Moreover, the machine’s efficiency can lead to reduced labor costs and increased productivity, further enhancing its overall value. When evaluating the cost of a Benchmate Labelling Machine, businesses should take into account not only the upfront investment but also the potential savings and return on investment (ROI) over the long term.

Differences Between Benchmate and Other Labelling Machines

The Benchmate Labelling Machine stands out from other labelling solutions in several ways. One of the main differences is its focus on standardization and versatility. While custom labelling machines are designed for specific applications and may offer specialized features, the Benchmate is built to accommodate a wide range of products and label types. This flexibility allows businesses to use a single machine for multiple applications, reducing the need for additional equipment and simplifying the production process.

Another key difference is the Benchmate’s cost-effectiveness. Custom machines often come with a higher price tag due to the specialized components and design work involved. In contrast, the Benchmate’s standardized nature allows for more efficient production and lower costs. This makes it an ideal choice for companies that need a reliable, all-purpose labelling solution without the expense of custom machinery. Additionally, the Benchmate’s ease of use and minimal training requirements make it accessible to a broader range of operators, further enhancing its appeal.

How to Choose the Right Benchmate Labelling Machine

Choosing the right Benchmate Labelling Machine involves considering several key factors. First, assess your production volume and capacity requirements. Determine the number of products you need to label per hour and ensure that the machine you choose can handle this workload. It’s also important to consider the types of labels you’ll be using and whether the machine can accommodate them. The Benchmate is designed to work with a variety of label materials and adhesives, making it a versatile choice for different applications.

Another crucial factor is budget. While the Benchmate is generally more affordable than custom machines, prices can still vary based on the model and features. Additionally, think about future growth and scalability. Choose a machine that can be easily upgraded or modified to meet changing production needs. By carefully evaluating these factors, you can select a Benchmate Labelling Machine that aligns with your business goals and operational requirements.

Suppliers and Purchasing Channels

When purchasing a Benchmate Labelling Machine, it’s essential to choose a reputable supplier. Look for suppliers with a proven track record of providing high-quality equipment and excellent customer service. Read reviews and testimonials from other customers to gauge their experiences and satisfaction levels. A reliable supplier will offer comprehensive support, including installation, training, and maintenance services. They should also provide clear and transparent pricing, with no hidden fees or charges.

In addition to traditional suppliers, you can also explore online purchasing channels. Many manufacturers and distributors offer online platforms where you can browse and purchase equipment. These platforms often provide detailed product descriptions, specifications, and customer reviews, helping you make an informed decision. However, it’s crucial to verify the legitimacy of the seller and ensure they offer secure payment options and warranties. By carefully selecting a supplier and purchasing channel, you can acquire a Benchmate Labelling Machine that meets your needs and expectations.

Conclusion

The Benchmate Labelling Machine is a versatile and cost-effective solution for a wide range of industries. Its adaptability, precision, and user-friendly design make it an excellent choice for businesses looking to streamline their labelling processes. Whether you’re labelling cylindrical products like water pipes and bottles or exploring new applications, the Benchmate offers reliable performance and excellent value. For more information or to get a quote, feel free to contact us. We’re here to help you find the perfect labelling solution for your needs.