Whether you’re in food and beverage, pharmaceuticals, or electronics, the choice you make will significantly impact your production efficiency and bottom line. This guide will help you navigate the complexities of selecting the perfect benchmark labelling machine for your industry.

Benchmark labelling machines are standardized, mass-produced solutions suitable for various industries. They offer cost-effective, reliable performance for general labeling needs without customization. These machines are ideal for companies looking for quick, efficient setup and versatile applications. Choosing the right one involves assessing production volume, label compatibility, and ease of use.

Let’s dive into what makes benchmark labelling machines a preferred choice and how to select the best one for your operations.

What Are Benchmark Labelling Machines?

Benchmark labelling machines are standardized, mass-produced machines that serve a broad spectrum of industries. Unlike custom labelling machines, which are tailored to specific products or processes, benchmark machines are designed for general use. This makes them an excellent choice for businesses looking to streamline operations without the need for specialized equipment.

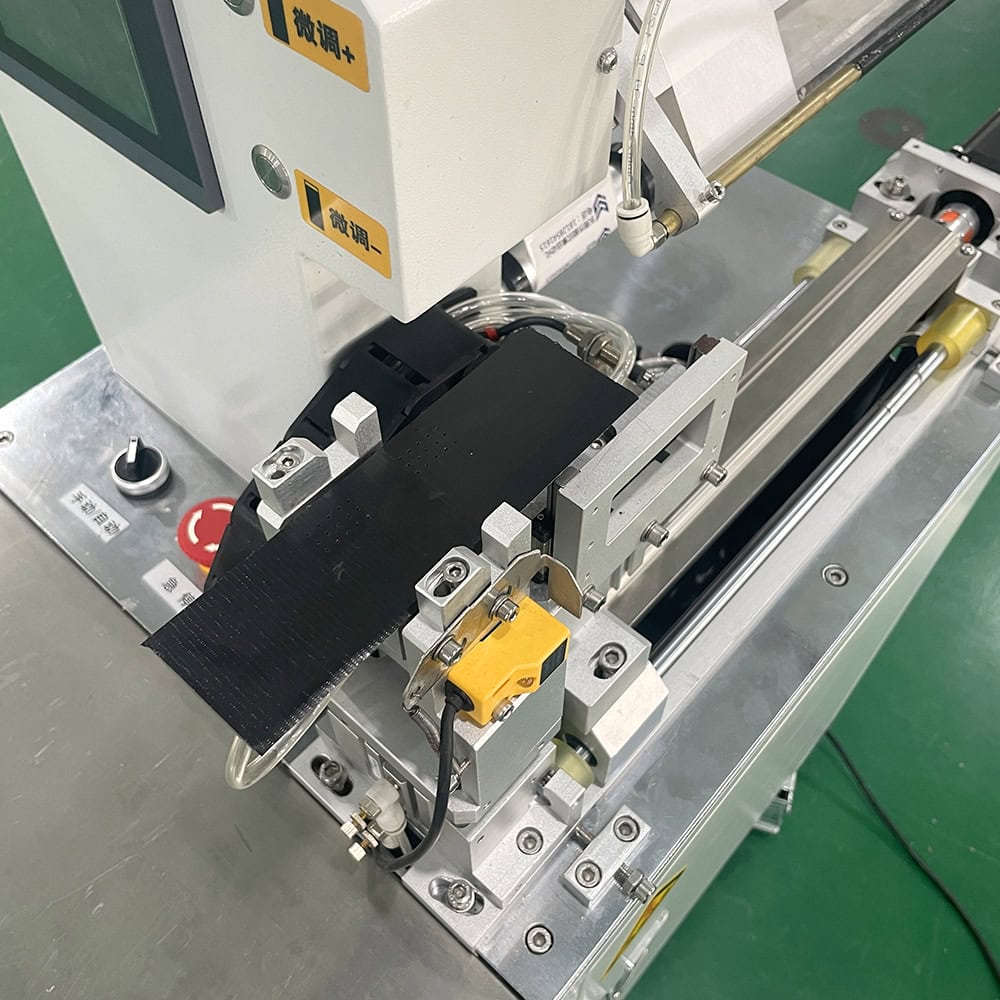

These machines are typically built with versatility in mind. They can handle a variety of label types, from pressure-sensitive labels to shrink sleeves, and are compatible with different container shapes and sizes. This flexibility is particularly valuable in industries where product lines frequently change, as it allows companies to switch between different products without significant downtime or reconfiguration. For example, this Standard Cable Labeler is a benchmark labeling machine that we manufacture at LabeMachine.

Advantages of Benchmark Labelling Machines

One of the primary advantages of benchmark labelling machines is their cost-effectiveness. These machines are generally less expensive than custom-built alternatives, making them an attractive option for small to medium-sized enterprises. The standardized design also means that manufacturers can produce them in bulk, further reducing costs. This affordability, however, doesn’t come at the expense of quality; benchmark machines are built to meet industry standards and deliver reliable performance.

Another significant benefit is their wide range of applications. Benchmark labelling machines are not tied to a specific industry or product type. This makes them a versatile solution for businesses that need to label different products or operate in various sectors. The ease of use and straightforward design also mean that they require minimal training for operators, reducing the learning curve and enabling quicker integration into existing production lines.

Common Features of Benchmark Labelling Machines

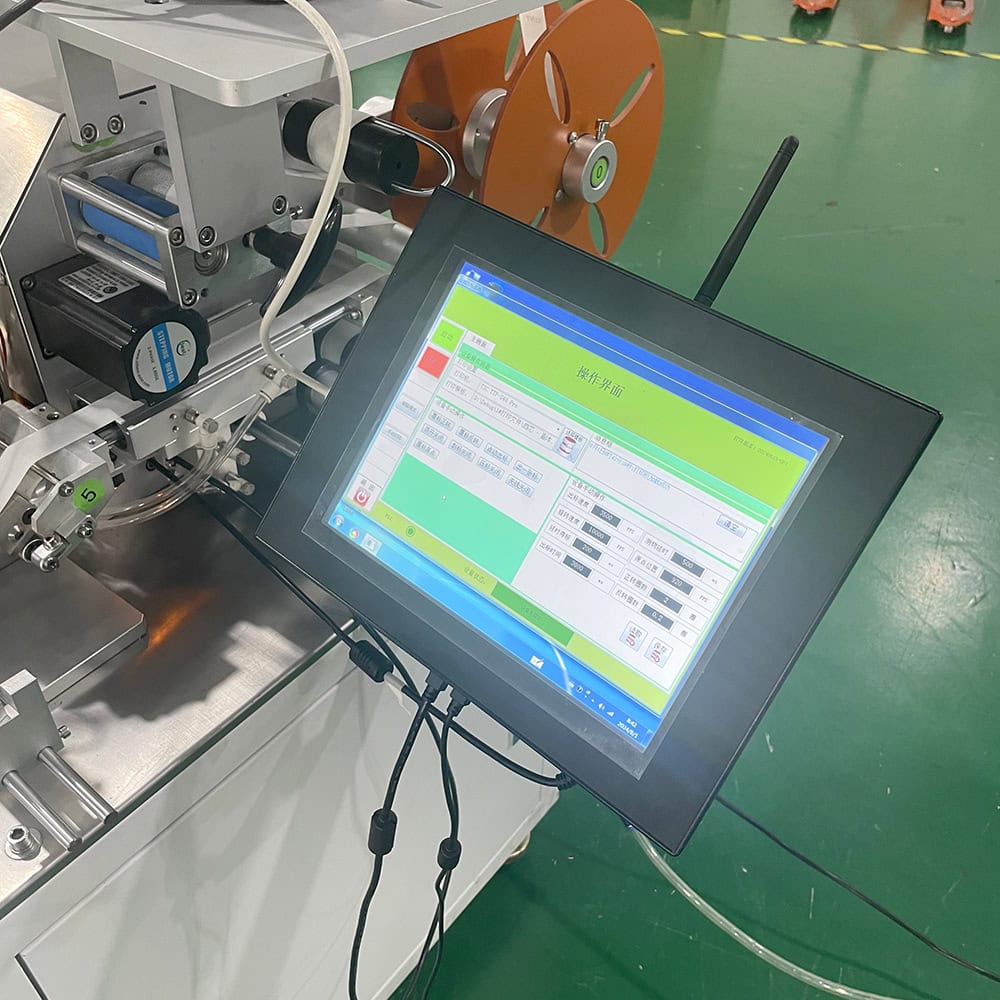

Benchmark labelling machines are equipped with essential features that make them suitable for a wide array of applications. These machines often come with adjustable settings, allowing operators to fine-tune the labelling process to match the specific needs of different products. For instance, you can adjust the speed, label placement, and adhesive strength, ensuring optimal performance across various scenarios.

Another common feature is the integration of advanced technologies, such as touch-screen controls and programmable logic controllers (PLCs). These features not only make the machines easier to operate but also enhance their precision and accuracy. Additionally, many benchmark labelling machines include automated label detection and rejection systems, which help minimize errors and reduce waste. These features collectively make benchmark labelling machines a reliable choice for businesses looking to improve efficiency and maintain high-quality standards.

Applications in Various Industries

Benchmark labelling machines find applications in numerous industries, thanks to their versatile nature. In the food and beverage sector, these machines are used to label everything from bottled beverages to packaged snacks. They can handle different types of labels, including nutritional information, branding, and barcodes, ensuring that products comply with regulatory requirements and meet consumer expectations.

In the pharmaceutical and healthcare industries, benchmark labelling machines play a critical role in ensuring the accurate and consistent labelling of medications and medical devices. These industries require high precision and reliability, and benchmark machines deliver on both fronts. The ability to handle various label types, such as tamper-evident seals and dosage instructions, makes them indispensable in maintaining product integrity and safety.

Comparison with Custom Labelling Machines

While benchmark labelling machines offer numerous benefits, they are not without limitations. One significant difference between benchmark and custom labelling machines is flexibility. Custom machines are designed to meet specific needs, offering features and capabilities tailored to unique products or processes. This customization can be particularly advantageous for businesses with specialized requirements, such as unique label shapes or materials.

However, custom machines often come with a higher price tag and longer lead times. They require detailed specifications and extensive testing to ensure they meet the desired performance standards. In contrast, benchmark machines are readily available and can be quickly integrated into existing production lines. For businesses with standard labelling needs, benchmark machines offer a more practical and economical solution.

Factors to Consider When Choosing a Benchmark Labelling Machine

When selecting a benchmark labelling machine, several factors should be considered. Production volume is one of the most critical aspects. Companies need to assess their output requirements and choose a machine that can handle the expected workload without compromising quality. Another important factor is the type of labels used. Different products may require specific label materials, adhesives, or application methods, so it’s essential to choose a machine compatible with these needs.

Ease of operation and maintenance is another key consideration. Benchmark labelling machines are designed to be user-friendly, but it’s crucial to ensure that the machine you choose is easy to set up, operate, and maintain. Look for machines with intuitive controls, accessible components, and robust support from the manufacturer. This will minimize downtime and ensure that your production line runs smoothly.

Bulk Production and Availability

One of the standout features of benchmark labelling machines is their availability. Since these machines are mass-produced, they are generally available in large quantities, allowing businesses to purchase multiple units if needed. This bulk availability is particularly beneficial for companies looking to scale their operations quickly. It also means that spare parts and accessories are readily available, reducing the risk of prolonged downtime due to maintenance or repairs.

Furthermore, the production of benchmark machines in bulk allows manufacturers to offer these machines at competitive prices. This cost advantage, combined with the machines’ versatility and reliability, makes them an appealing choice for businesses across various industries. Companies can invest in a high-quality labelling solution without breaking the bank, ensuring they get the best value for their money.

Cost Considerations and ROI

Cost is a significant factor when choosing a benchmark labelling machine. While these machines are generally more affordable than custom-built alternatives, it’s essential to consider the total cost of ownership. This includes not only the initial purchase price but also ongoing costs such as maintenance, consumables, and energy consumption. By evaluating these factors, businesses can determine the most cost-effective option for their needs.

The return on investment (ROI) is another critical consideration. Benchmark labelling machines offer a quick and reliable solution for many industries, enabling businesses to start production without extensive customization. The faster setup and integration times mean that companies can begin reaping the benefits sooner, resulting in a faster ROI. By carefully assessing the total cost and potential benefits, businesses can make an informed decision that aligns with their financial goals.

Making the Right Choice

Selecting the right benchmark labelling machine involves careful consideration of several factors. It’s essential to evaluate the machine’s features, capabilities, and compatibility with your specific needs. Additionally, it’s crucial to choose a reputable supplier or manufacturer who can provide reliable support and service. This ensures that any issues can be promptly addressed, minimizing downtime and maximizing productivity.

One effective way to make the right choice is to consult with industry experts or peers who have experience with similar equipment. They can provide valuable insights into the strengths and weaknesses of different machines and suppliers. Additionally, visiting trade shows or manufacturer facilities can give you a hands-on experience and help you make an informed decision.

Conclusion

Benchmark labelling machines offer a versatile and cost-effective solution for a wide range of industries. By understanding their benefits and limitations, businesses can select the right machine to meet their specific needs. Whether you’re looking to streamline your production line, reduce costs, or enhance product quality, a benchmark labelling machine can be an invaluable asset. Choose wisely and invest in a solution that will deliver long-term value and performance.