Labeling products manually can be a time-consuming and error-prone process. One solution is the use of auto label machines, which automate the labeling process, reducing the need for manual intervention and minimizing errors. Whether you are a small business or a large-scale manufacturer, understanding how auto label machines can improve your operations is crucial.

Auto label machine significantly enhance efficiency by automating the labeling process. These machines can handle high-speed operations with precision, ensuring consistent and accurate label placement. They reduce the need for manual labor, thus minimizing the risk of errors and saving time and costs associated with manual labeling. Additionally, they can handle various label types and sizes, making them versatile for different industries.

Many businesses are hesitant to invest in automation due to concerns about costs. However, the long-term benefits and efficiency gains from auto label machines often outweigh the initial investment.

The Benefits of Auto Label Inspection Machines

Auto label inspection machines are essential for ensuring the quality and accuracy of labels. These machines use advanced sensors and cameras to detect misalignments, missing labels, or other defects. By automating the inspection process, businesses can maintain high-quality standards and prevent defective products from reaching the market. This not only saves costs associated with returns and recalls but also enhances brand reputation.

Understanding Auto Label Machine Prices

When considering the purchase of an auto label machine, price is a significant factor. The cost of these machines can vary widely based on features, speed, and customization options.

While it may be tempting to opt for a cheaper model, investing in a high-quality machine can provide better long-term value. It’s essential to consider the total cost of ownership, including maintenance, energy consumption, and potential downtime. If you need to get the specific product price, please contact us.

Auto Label Pasting Machines for Versatile Applications

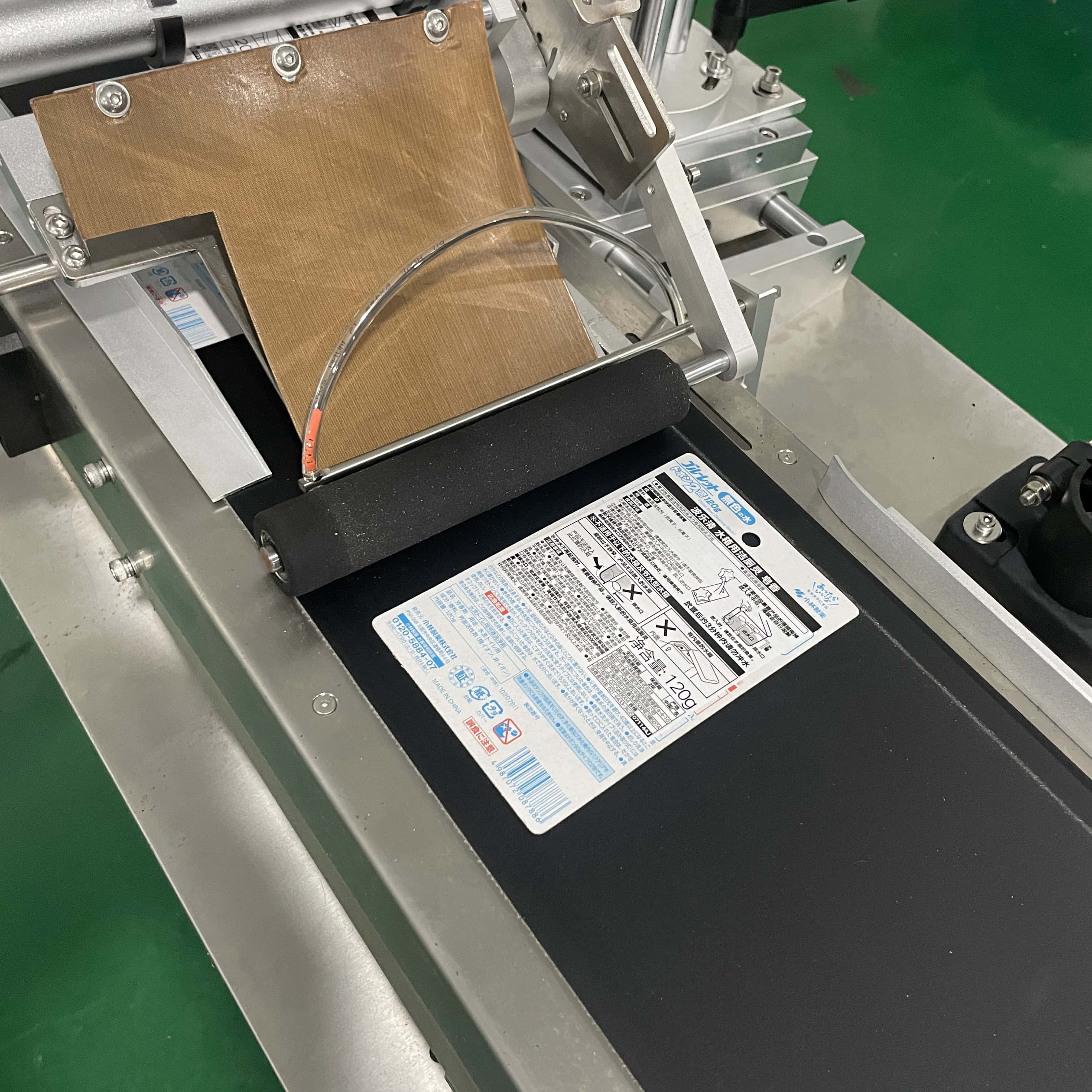

Auto label pasting machines are designed to apply labels to a wide range of products, including bottles, boxes, and packages. These machines can handle different label materials, such as paper, plastic, or metal, making them suitable for various industries. They are particularly useful in food and beverage, pharmaceuticals, and cosmetics, where precise labeling is crucial for compliance and branding.

The Role of Auto Labeling Machines in Modern Manufacturing

Auto labeling machines have become a staple in modern manufacturing due to their ability to streamline production processes. These machines can be integrated into existing production lines, providing seamless operation and reducing manual handling. They are capable of handling high-speed operations, ensuring that labels are applied quickly and accurately. This not only increases production efficiency but also reduces the risk of contamination and damage to products.

Exploring Auto Labeling Machine Learning

The integration of machine learning in auto labeling machines has revolutionized the industry. These machines can learn and adapt to different labeling requirements, making them more efficient and versatile. With machine learning algorithms, they can optimize label placement, adjust to varying product sizes, and even detect anomalies. This technology not only improves accuracy but also reduces downtime by predicting maintenance needs.

The Importance of Auto Labelling Machines in Compliance

In many industries, compliance with labeling regulations is critical. Auto labelling machines ensure that all products are labeled correctly with necessary information such as ingredients, expiration dates, and warnings. This is especially important in industries like food and pharmaceuticals, where incorrect labeling can lead to legal issues and health risks. By automating the labeling process, businesses can ensure compliance with regulations and avoid costly fines.

Conclusion

Investing in auto label machines is a smart decision for businesses looking to improve efficiency, accuracy, and compliance. While the initial cost may be a concern, the long-term benefits, including reduced labor costs and improved product quality, make it a worthwhile investment. With advancements in technology, these machines continue to evolve, offering even greater capabilities and features.

That’s it! By leveraging the power of auto label machines, businesses can stay ahead of the competition and ensure a smooth and efficient labeling process.