In today’s fast-paced market, businesses need efficient solutions to stay competitive. One such solution is the adhesive labelling machine, which plays a crucial role in packaging and branding. Whether you’re labeling bottles, boxes, or other products, this equipment can significantly enhance your production line’s speed and accuracy.

Adhesive labelling machines offer a versatile and efficient way to apply labels to a wide variety of products. They are essential for businesses looking to improve labeling precision and consistency, ultimately leading to better brand presentation and customer satisfaction.

Beyond enhancing efficiency, these machines provide a reliable way to manage large volumes of products, ensuring each item is correctly labeled. This is critical for maintaining brand integrity and meeting regulatory requirements.

What Makes Adhesive Labelling Machines So Important?

Adhesive labelling machines are vital because they automate the process of applying labels. This automation saves time and reduces errors compared to manual labeling. For example, in a high-volume production setting, a label die cutting machine can quickly and precisely cut labels, which are then applied by the adhesive labelling machine. This combination of technologies ensures that labels are not only accurate but also durable.

How Do Adhesive Labelling Machines Enhance Product Presentation?

The appearance of a product can significantly influence consumer purchasing decisions. Adhesive label printing machines allow businesses to customize labels with vibrant colors, unique designs, and detailed information. This customization is not only a marketing tool but also a way to comply with industry standards for information display. By using an adhesive labelling machine, companies can ensure that their products stand out on the shelves.

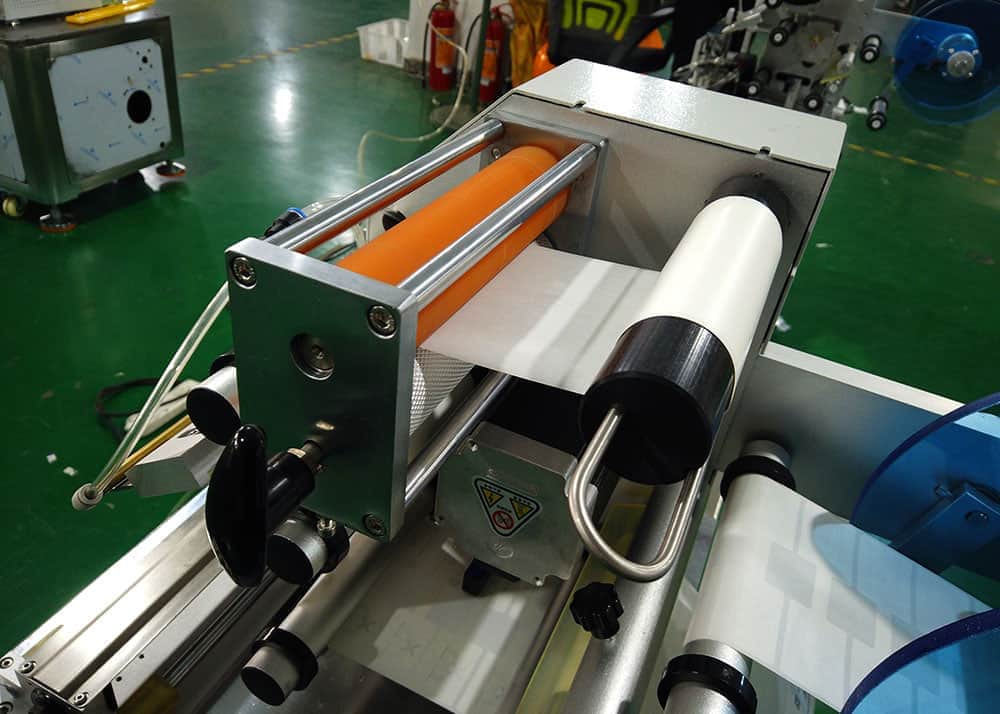

The Role of Adhesive Label Die Cutting Machines

In conjunction with adhesive labelling machines, adhesive label die cutting machines play a crucial role in the labeling process. These machines precisely cut labels to the required shapes and sizes, ensuring a perfect fit on each product. This precision is particularly important for products with unique shapes or surfaces, where standard labels may not adhere properly.

The Efficiency of Automated Labeling

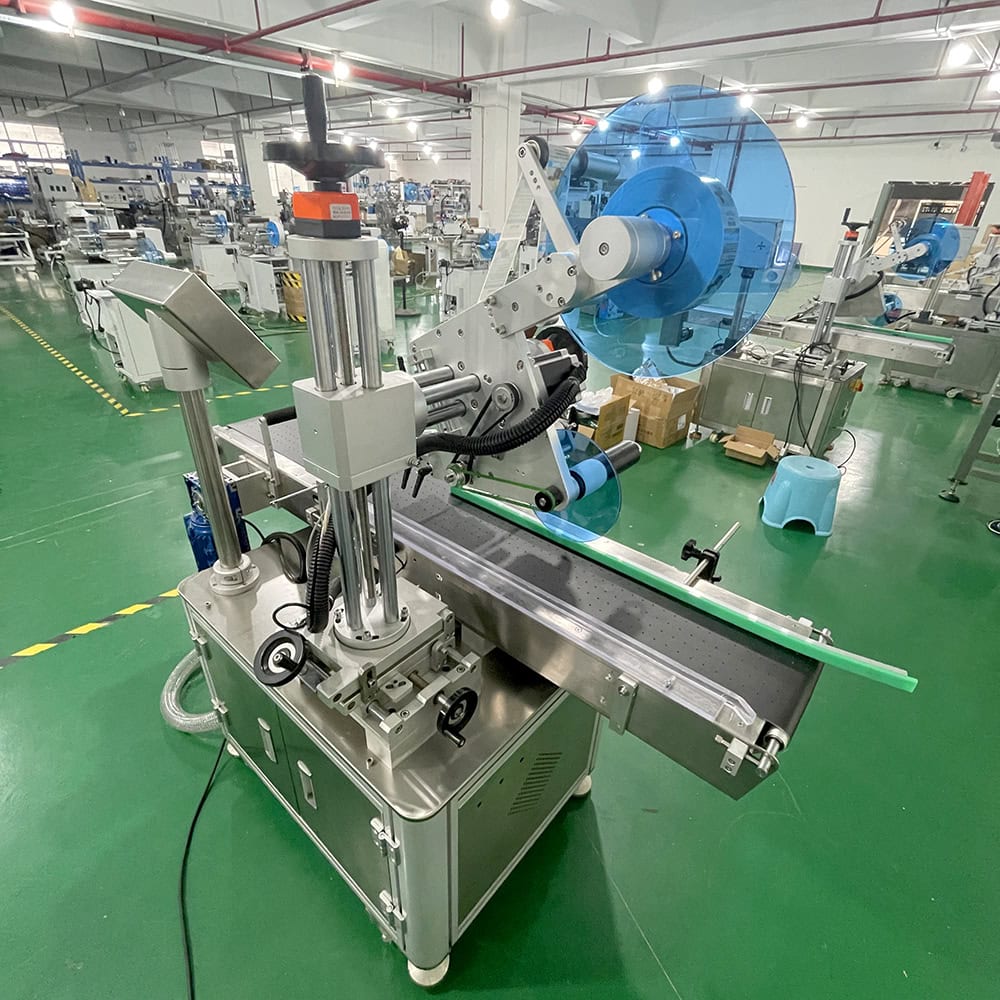

One of the key benefits of using adhesive labelling machines is the increased efficiency they bring to production lines. These machines can apply labels at high speeds, allowing businesses to scale up production without compromising quality. For instance, an adhesive labelling machine can work in tandem with other automation equipment, such as filling or packaging machines, to streamline the entire production process.

Versatility in Labeling Different Products

Adhesive labelling machines are versatile enough to handle various product types, from cylindrical bottles to flat boxes. This versatility makes them a valuable asset for businesses in multiple industries, including food, beverage, cosmetics, and pharmaceuticals. With the ability to adjust settings for different label sizes and types, these machines can accommodate a wide range of labeling needs.

The Cost-Effectiveness of Investing in Labelling Machines

While the initial investment in an adhesive labelling machine may seem significant, the long-term benefits far outweigh the costs. These machines reduce labor costs by automating the labeling process and minimizing errors that can lead to product recalls or rework. Additionally, they help businesses maintain consistent label quality, which is essential for brand reputation and customer trust.

How to Choose the Right Adhesive Labelling Machine

Selecting the right adhesive labelling machine depends on several factors, including the type of products you manufacture, the production volume, and the specific labeling requirements. It’s essential to consider the machine’s speed, accuracy, and compatibility with other production equipment. Consulting with a professional who has extensive experience in automation equipment can help you make an informed decision.

Conclusion

Adhesive labelling machines are a critical investment for businesses aiming to streamline their production processes and enhance product presentation. By automating the labeling process, these machines improve efficiency, reduce costs, and ensure consistent quality. Whether you’re a small business or a large manufacturer, the right adhesive labelling machine can make a significant difference in your operations.