Finding the right label applicator machine can be a daunting task, especially with so many options on the market. If you’re struggling to select the perfect machine for your flat surface labeling needs, you’re not alone. Many businesses face the same challenge, unsure where to begin or what factors to consider.

Choosing the best label applicator machine for flat surfaces involves understanding your specific needs, the machine’s capabilities, and the quality of the labels it can produce. A careful analysis of these aspects will guide you to the right choice.

Stick with me as we delve into the key considerations that will help you make an informed decision.

Understanding Your Labeling Needs

When selecting a label applicator machine, the first step is to understand your specific labeling needs. What type of products are you labeling? The size, shape, and material of your products can significantly impact the type of machine you should choose. For instance, labeling a flat surface, like a box or a flat-sided bottle, requires a machine designed to handle these specific surfaces efficiently.

Consider the volume of labeling you’ll be doing. If you have a high production rate, you’ll need a machine that can keep up without compromising on precision. Conversely, for smaller operations, a less robust, but equally precise, machine might be more suitable. By clearly defining your requirements, you can narrow down the options and focus on machines that meet your specific needs.

LabeMachine provides different forms of labeling machines, especially if you have requirements for labeling accuracy, then you use our CCD Camera Vision Flat Labeling Machine, which can reach an accuracy of ±0.1mm, if you do not have high requirements for accuracy, then you can use our ordinary flat labeling machine.

Machine Capabilities and Features

Once you’ve outlined your needs, the next step is to evaluate the capabilities and features of different machines. Look for a machine that offers precision and reliability. The accuracy of label placement is crucial, especially for products with strict regulatory requirements or high aesthetic standards. Features like automated adjustments for different label sizes and shapes can save time and reduce errors.

Consider the ease of integration into your existing production line. A machine that’s difficult to set up or operate can cause delays and increase costs. Look for user-friendly interfaces and comprehensive support from the manufacturer. Machines with versatile functionality, such as the ability to handle various label types and sizes, will offer greater flexibility and adaptability for future needs.

Quality of Labels

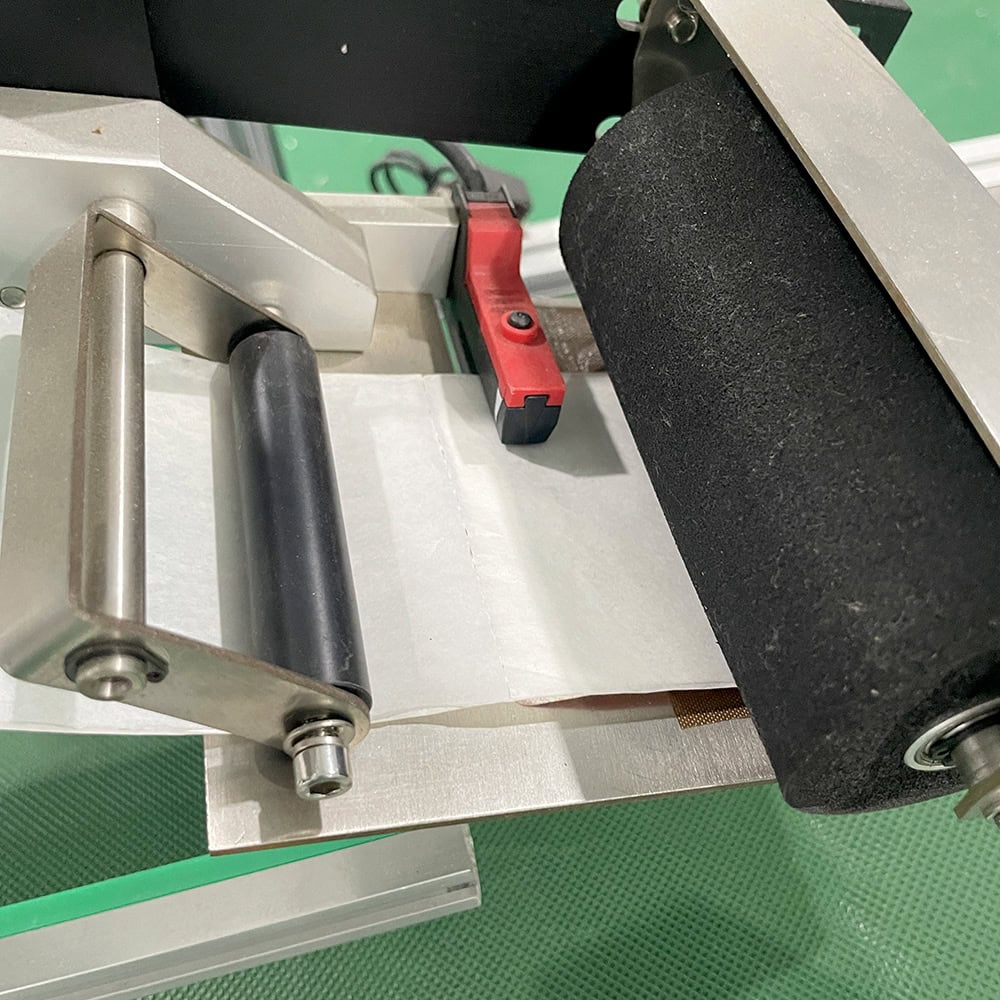

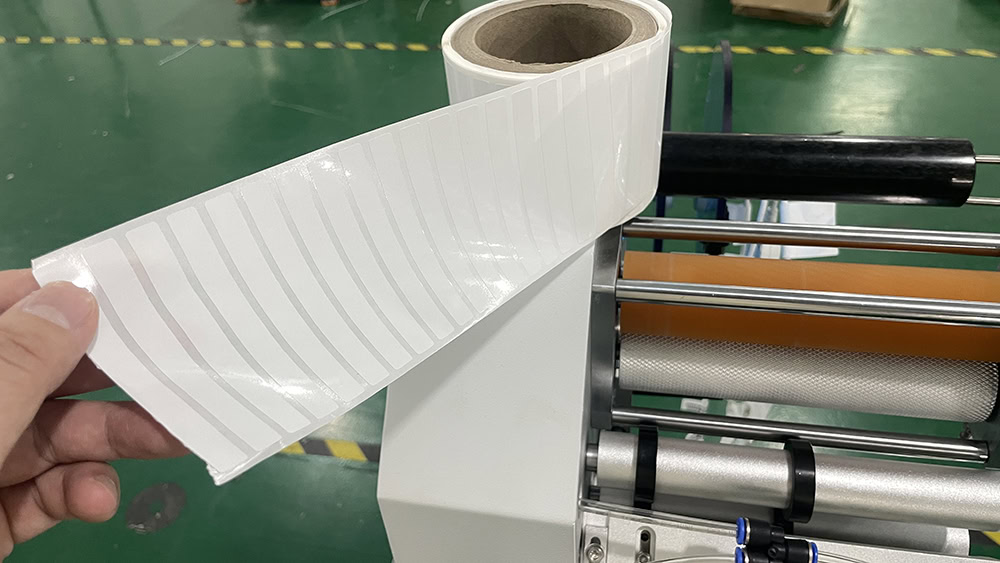

The quality of the labels produced is another vital factor. High-quality labels are essential for maintaining brand reputation and ensuring compliance with industry standards. A good label applicator machine should apply labels without wrinkles, bubbles, or misalignment. This not only improves the visual appeal of your products but also ensures that all necessary information is legible and accurate.

Check the machine’s ability to handle different label materials and adhesives. Some machines may struggle with certain types of labels, leading to poor application quality. It’s also worth considering machines that offer options for thermal transfer or direct thermal printing if you need on-demand, high-quality labels. LabeMachine offers high quality industrial printers.

Cost vs. Value

Price is always a consideration, but it’s important to focus on value rather than just the initial cost. A cheaper machine may save money upfront but could lead to higher costs in the long run due to maintenance issues, downtime, or poor label quality. Investing in a reliable, high-quality machine can offer better long-term returns.

Consider the total cost of ownership, which includes maintenance, parts replacement, and operational costs. Look for machines with good warranties and support packages. This can provide peace of mind and ensure that any issues are quickly resolved, minimizing disruption to your operations.

Customer Support and Training

The level of customer support and training provided by the manufacturer is another critical aspect. A machine is only as good as the support that comes with it. Comprehensive training ensures that your staff can operate the machine efficiently and troubleshoot minor issues. Excellent customer support can save valuable time and prevent costly downtime.

Look for manufacturers that offer extensive training programs, whether onsite or online. Ensure they have a responsive support team that can assist with any technical issues. Reviews and testimonials from other customers can provide insights into the level of support you can expect.

If you purchase our labeling equipment, we provide 1 year warranty service and permanent technical support. Or you can get the latest product knowledge and questions answered on the resources page of our website.

Conclusion

Selecting the best label applicator machine for flat surfaces requires careful consideration of your specific needs, the machine’s capabilities, the quality of labels it produces, and the value it offers. With thorough research and analysis, you can find a machine that meets your requirements and supports your business’s growth.

That’s it for now! Happy labeling!