In my 20+ years in the automation equipment industry, I’ve seen a wide range of factors that influence the price of manual labeling machines. Understanding these factors can help you make an informed decision and ensure you get a machine that meets your needs without overspending.

So, what exactly influences the price of a manual labeling machine? Several key factors come into play, including the type of machine, labeling accuracy and speed, complexity of the products being labeled, core components of the equipment, quantity purchased, and whether the machine is standard or customized.

Let’s break down these factors in more detail.

How Does the Type of Labeling Machine Affect the Price?

The type of manual labeling machine you choose significantly impacts the price. Different machines are designed for specific applications and industries. For instance, some machines are designed for bottle labeling, while others are better suited for flat surfaces or odd-shaped products.

Choosing the right type of machine is crucial. If you select a machine that is not optimized for your specific labeling needs, you may face issues like poor label alignment or increased labor costs due to inefficiencies. Over the years, I’ve seen how investing in the right type of machine can save both time and money in the long run.

Why Do Labeling Accuracy and Speed Matter?

Labeling and speed are critical factors that influence the price of a manual labeling machine. High-precision machines that can apply labels accurately and consistently are typically more expensive. Similarly, machines that offer faster labeling speeds tend to cost more.

In high-volume operations, even small improvements in speed and accuracy can lead to significant cost savings. An accurate machine reduces label waste and rework, while a faster machine increases throughput. From my experience, investing in a machine with the right balance of speed and accuracy pays off quickly.

How Does Product Complexity Influence Cost?

The complexity of the products being labeled also affects the price of the machine. Products with irregular shapes or varying sizes often require more sophisticated labeling solutions. Machines that can handle these complexities usually come with higher price tags.

For example, labeling machines designed for cylindrical bottles are generally less expensive than those designed for odd-shaped containers or multi-sided labeling. Understanding the specific needs of your products is essential to choosing the right machine without overpaying for unnecessary features.

What Role Do Core Components Play in Pricing?

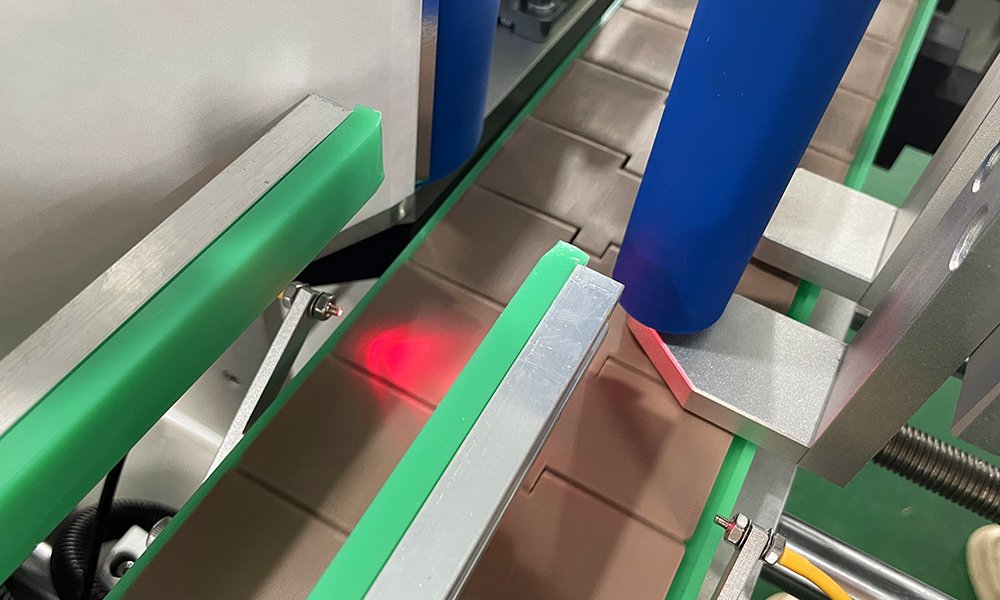

The quality and type of core components used in the labeling machine also influence its price. High-quality components like motors, sensors, and control systems can significantly impact the machine’s performance and durability.

Machines with premium components tend to be more reliable and require less maintenance, leading to lower long-term costs. In my factory, we always prioritize machines with robust components, as they offer better performance and longevity, ultimately providing better value for money.

How Does Purchase Quantity Affect the Price?

The quantity of machines purchased can also affect the price. Bulk purchases often come with discounts, reducing the overall cost per unit. Manufacturers and suppliers are usually willing to offer better pricing for larger orders.

If you’re planning to scale up your operations, consider negotiating bulk purchase deals. In my experience, buying in larger quantities not only lowers the unit price but also ensures consistent performance across your production lines.

Is There a Difference Between Standard and Custom Machines?

Standard machines are generally less expensive than custom-built ones. Custom machines are designed to meet specific requirements and often include specialized features that standard models do not offer. For example, Standard Cable Labeler is our standard machine.

While custom machines can be more expensive upfront, they are tailored to your exact needs, potentially offering greater efficiency and better performance. It’s essential to weigh the benefits of customization against the additional cost to determine what makes the most sense for your operation.

What Other Factors Should You Consider?

Beyond the main factors mentioned, there are other aspects to consider. These include after-sales service, warranty terms, and the brand reputation of the manufacturer. Reliable after-sales service can save significant costs in the long run, while a good warranty provides peace of mind.

Additionally, well-known brands often come with a higher price tag, but they also offer proven reliability and better support. Over the years, I’ve found that investing in reputable brands and robust after-sales service can prevent costly downtimes and ensure smoother operations.

Conclusion

Understanding the various factors that affect manual labeling machine prices helps in making informed purchasing decisions. Whether you’re considering the type of machine, its accuracy and speed, product complexity, core components, purchase quantity, or whether to go for a standard or custom machine, each factor plays a crucial role in determining the price.