In today’s complex network environments, maintaining an organized and efficient cabling system is essential. Mismanagement of network cables can lead to downtime, increased troubleshooting time, and inefficiencies. This is where a comprehensive network cable labeling system comes into play.

A network cable labeling system provides a structured approach to managing network cables. By clearly labeling cables, you can reduce downtime, simplify troubleshooting, and improve overall network efficiency. It’s a simple yet powerful tool for network administrators.

Effective cable labeling is crucial for network management. Let’s delve into the specifics of how a labeling system can benefit your network infrastructure.

The Importance of Network Cable Label Sheets

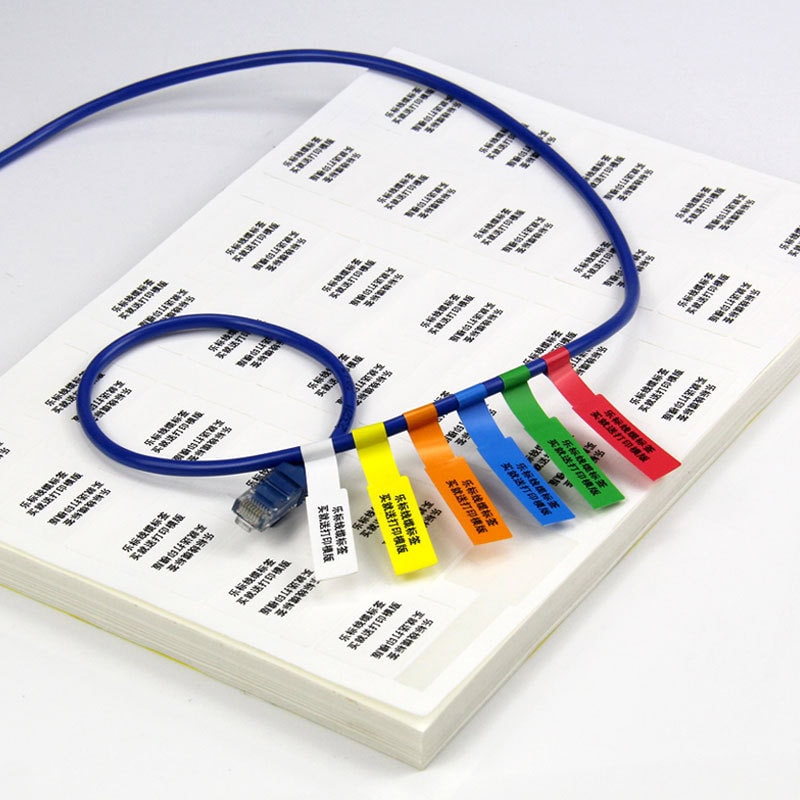

Network cable label sheets are foundational in setting up a labeling system. These sheets are pre-formatted for easy printing, often compatible with standard printers. They allow for consistent, clear, and durable labeling. By using these sheets, you can ensure each cable is marked with relevant information such as its function, destination, or source.

The use of label sheets helps avoid confusion during installation and maintenance. Network administrators can quickly identify cables, reducing the time spent searching for specific connections. This efficiency translates to lower downtime and increased productivity.

Benefits of Network Cable Label Tags

Label tags are another essential component of a labeling system. Made from durable materials like plastic or vinyl, these tags withstand harsh conditions often found in network environments. They can be attached to cables using various methods, such as clips or adhesive backing.

Tags offer flexibility in labeling. They can include more detailed information compared to label sheets, such as barcodes, QR codes, or custom messages. This makes them ideal for complex networks where cables may serve multiple functions or connect to various devices.

Implementing a Network Cable Labeling System

A comprehensive network cable labeling system integrates various tools and methodologies. It often includes label sheets, tags, printers, and software. The system ensures that all cables are uniformly labeled, facilitating easier identification and management.

Investing in a labeling system can seem costly initially, but the long-term benefits outweigh these costs. Improved organization leads to quicker problem resolution, fewer errors during installations, and better overall network performance.

Network Cable Labels and Laser Printers

Laser printers play a crucial role in producing high-quality labels. They offer precision and durability, ensuring that labels remain legible over time. Using a laser printer for your labeling needs guarantees that the labels will withstand environmental factors such as heat and humidity.

Additionally, laser printers can handle various label materials, from paper to synthetic substrates. This versatility is beneficial when creating labels for different types of cables and environments.

Using Network Cable Number Labels

Number labels simplify the identification process by assigning unique identifiers to each cable. This numbering system helps track connections and configurations across the network. Number labels are particularly useful in large-scale networks where manual tracking can be challenging.

By implementing number labels, network administrators can quickly reference and locate specific cables, enhancing the efficiency of maintenance and troubleshooting tasks.

The Role of Network Patch Cable Labels

Patch cables are integral to network connectivity, linking various devices and components. Labeling these cables is vital to maintaining an organized network. Patch cable labels help in identifying the purpose and connection points of each cable.

Clear labeling of patch cables reduces the risk of unplugging the wrong cable, which can lead to network outages. It also facilitates easier changes and upgrades to the network infrastructure.

Conclusion

A well-implemented network cable labeling system is essential for efficient network management. From label sheets and tags to numbering systems and laser printers, each component plays a vital role. Investing in such a system enhances organization, reduces downtime, and improves overall network performance. By ensuring that every cable is clearly labeled and easily identifiable, you can maintain a robust and efficient network.