In today’s fast-paced technological world, managing network cables efficiently is crucial. Without a proper labeling system, network maintenance becomes a nightmare. Mislabeling or not labeling UTP cables can lead to significant downtime and errors, costing businesses time and money. Implementing a robust UTP cable labeling system can streamline cable management, reduce errors, and enhance operational efficiency.

A UTP cable labeling system is an organized approach to identifying and managing unshielded twisted pair cables in a network. This system comprises several components, including labels, label printers, and software, designed to make cable management easier and more efficient.

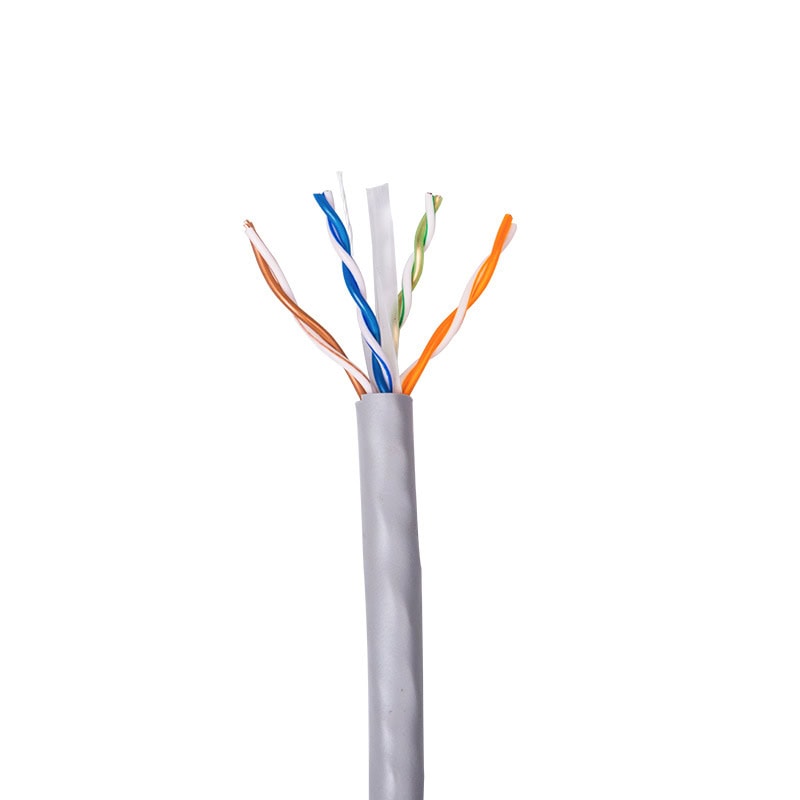

What Does UTP Mean in Cable?

UTP stands for Unshielded Twisted Pair. It is a type of copper cable used extensively in networking and telecommunications. The “twisted pair” refers to the pairs of wires twisted together to reduce electromagnetic interference. Unlike Shielded Twisted Pair (STP), UTP cables do not have additional shielding, making them lighter and more flexible. This lack of shielding, however, makes them more susceptible to interference, which is why proper labeling and organization are essential.

Key Components of a Labeling System

A comprehensive labeling system includes several key components. First and foremost are the labels themselves. These labels need to be durable, easy to read, and resistant to environmental factors such as heat, moisture, and dust. They should also be easy to apply and adhere securely to the cables.

Label Printers and Software

Next is the label printer. This piece of equipment is crucial for creating custom labels on demand. A good label printer should be able to print clear, legible labels in various sizes and formats. It should also be compatible with different types of label materials, from standard paper labels to more durable plastic or vinyl options. Labeling software helps design and manage the labels, allowing users to create templates, save designs, and print labels efficiently.

Benefits of Using a Labeling System

Using a UTP cable labeling system offers numerous benefits. One of the primary advantages is improved organization. When every cable is properly labeled, it becomes much easier to manage and maintain the network. Technicians can quickly identify cables, reducing the time spent on troubleshooting and repairs. Another significant benefit is the reduction of errors. With clear, consistent labeling, the risk of connecting the wrong cables or making other mistakes is minimized.

Enhanced Safety and Efficiency

Additionally, a well-implemented labeling system can enhance safety. Properly labeled cables reduce the risk of accidents, such as tripping over loose cables or mistakenly cutting the wrong one. This is especially important in environments with many cables, such as data centers or server rooms.

Implementing the System in Your Network

Implementing a labeling system involves several steps. First, assess your current cable management practices and identify areas for improvement. This includes taking inventory of your existing cables and determining the types and quantities of labels needed. Next, select the appropriate wire labeling equipment and software. Consider factors such as label durability, printer capabilities, and software features.

Creating a Labeling Plan

Once you have the necessary equipment, you can begin labeling your cables. Start by creating a labeling plan that includes a consistent format for labels and a system for organizing and managing the labeled cables. This plan should be documented and shared with all relevant personnel to ensure consistency and accuracy.

Maintaining Your Labeling System

Maintaining your UTP cable labeling system is crucial for long-term success. Regularly check and update labels to ensure they remain readable and accurate. This also includes maintaining your labeling equipment, such as keeping the printer in good working order and ensuring you have an adequate supply of labels. Regular training and communication with your team are also important. Ensure that all technicians and relevant personnel are familiar with the labeling system and understand its importance.

Conclusion

Implementing and maintaining a UTP cable labeling system is essential for efficient network management. By investing in a comprehensive labeling system, you can improve organization, reduce errors, and enhance the overall reliability and safety of your network. With over 20 years of experience in the field of automation equipment, I can confidently say that a well-implemented labeling system is a game-changer for any business.

That’s it. Keep your network organized and efficient with a robust UTP cable labeling system.