Properly labeling cables is essential for maintaining an organized and efficient workspace, whether in a home office, data center, or industrial setting. Cable labeling helps in identifying and managing different cables, ensuring quick troubleshooting and reducing downtime. This guide will explore the best practices for labeling cables, the types of label makers available, and the importance of this often-overlooked task.

Understanding the Importance of Cable Labeling

Labeling cables is not just about keeping things neat; it’s about creating a system that allows for easy identification and management. When cables are labeled correctly, it becomes easier to perform maintenance, make upgrades, and resolve issues. For businesses, especially those dealing with complex networks, properly labeled cables can save significant time and resources.

Proper cable labeling helps avoid confusion, reduces the risk of errors, and ensures a streamlined workflow. In environments where multiple cables are running side by side, such as data centers or industrial facilities, the ability to quickly identify a specific cable can prevent costly downtime.

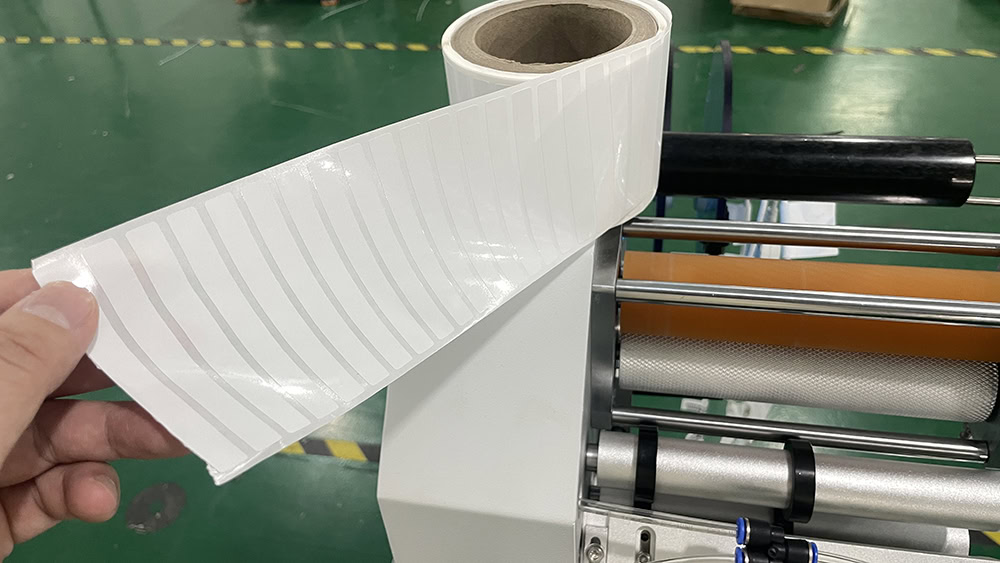

Choosing the Right Cable Label Maker

Selecting the appropriate cable label maker is crucial for effective labeling. There are various types of label makers designed specifically for cables, each offering different features to suit various needs. For instance, a network cable label maker is ideal for labeling Ethernet cables in a server room, while a more general cable label maker can be used for a variety of other cables.

When choosing a label maker for cables, consider the following:

- Ease of Use: The label maker should be easy to operate, allowing for quick and efficient labeling.

- Durability: Labels should be resistant to wear and tear, especially in industrial environments.

- Compatibility: Ensure the label maker can handle different cable sizes and types.

Investing in a quality label maker can enhance the efficiency of cable management and ensure labels remain legible over time.

Best Practices for Labeling Cables

To achieve the best results, it’s important to follow some best practices when labeling cables. These practices ensure that labels are clear, consistent, and durable.

1. Use Clear and Concise Labels

Labels should be easy to read and understand. Use abbreviations and symbols where appropriate, but ensure they are universally recognizable. For example, using “ETH” for Ethernet or “PWR” for power cables can help in quick identification.

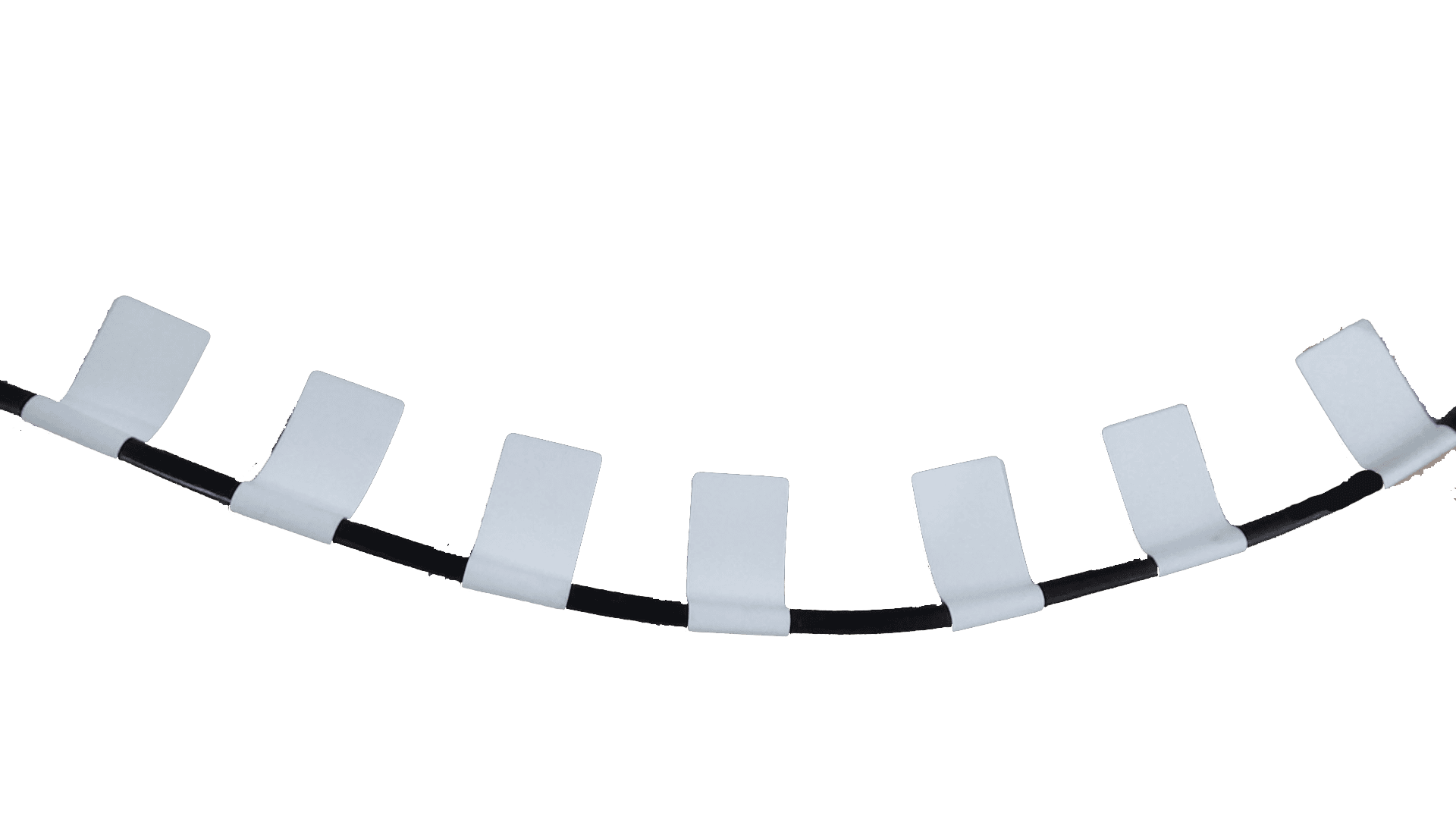

2. Place Labels Strategically

Labels should be placed at both ends of the cable to ensure they are visible regardless of how the cables are routed. For longer cables, consider placing additional labels at regular intervals.

3. Choose the Right Material

Labels should be made from durable materials that can withstand environmental factors such as heat, moisture, and abrasion. This is particularly important for cables in industrial settings or outdoor installations.

4. Maintain Consistency

Use a consistent labeling format across all cables. This includes using the same font size, color, and label placement. Consistency helps in quick identification and reduces the risk of errors.

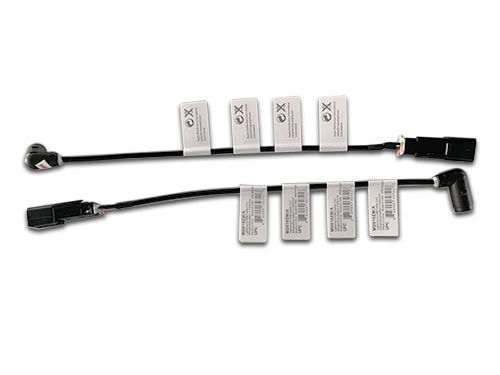

The Role of Network Cable Labels

In environments where network cables are prevalent, using network cable labels is essential. These labels help in identifying the function of each cable, such as whether it is for data transmission, power, or specific network segments.

Network cable labels can be pre-printed or custom-made using a network cable label maker. Custom labels allow for more specific information, such as the destination of the cable or the type of connection it supports.

Network cable labels are particularly useful in large data centers, where hundreds or thousands of cables are running. Proper labeling ensures that network technicians can quickly identify and troubleshoot issues.

Conclusion

Labeling cables might seem like a mundane task, but it plays a critical role in maintaining an organized and efficient workspace. By using the right cable label maker and following best practices, you can ensure that your cables are easy to identify and manage. Whether you are dealing with network cables in a data center or power cables in an industrial setting, proper labeling can save time, reduce errors, and enhance overall productivity.

Incorporating tools like a network cable label maker and adhering to consistent labeling practices will ensure that your cable management system is robust and reliable. Remember, a well-labeled cable is the first step towards a well-organized and efficient workspace.