When you’re investing in an automatic vial labeling machine, the stakes are high. A wrong choice can lead to production delays, costly errors, and reduced efficiency, affecting your business’s bottom line.

To make an informed decision, consider these 10 key points that will help ensure you choose the right machine for your specific needs. These factors will guide you through the process, ensuring you avoid common pitfalls and select a machine that delivers on quality, speed, and reliability.

By understanding these crucial aspects, you can make a confident purchase that supports your long-term business goals.

Understand Your Production Volume

Before diving into the purchase, it’s essential to assess your current and projected production volumes. The right vial labeling machine should not only meet your present needs but also accommodate future growth. A machine that is too small may lead to bottlenecks in production, while an oversized machine could mean unnecessary costs. Carefully evaluate your production data and consider seasonal fluctuations or potential expansions to ensure you choose a machine that aligns with your long-term production strategy.

Match the Machine with Your Vial Types

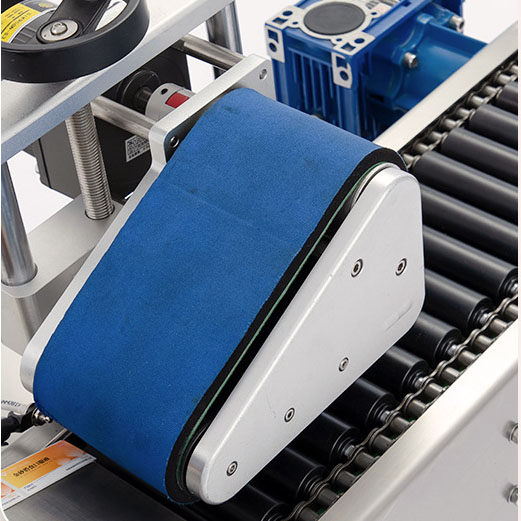

Not all vial labeling machines are created equal, and the type of vials you’re labeling plays a significant role in your choice. Consider the size, shape, and material of your vials. Some machines are better suited for certain vial types, providing more accurate labeling or higher speeds. For instance, if you’re working with fragile glass vials, you’ll need a machine designed to handle them delicately. Take for example this 15ml bottle labeling machine. On the other hand, for plastic vials, you might prioritize speed and versatility.

Ensure Compatibility with Your Labels

Your labeling machine must be compatible with the labels you plan to use. This includes not only the size and shape of the labels but also the material and adhesive properties. Certain machines are better equipped to handle different types of labels, whether they’re paper, plastic, or foil. Additionally, consider whether your labels require special features, such as tamper-evident seals or high-temperature resistance. Ensuring compatibility will prevent costly issues down the line, such as misalignment or label wastage.

Evaluate the Speed and Efficiency

Speed and efficiency are critical factors, especially in high-volume production environments. You’ll want a machine that can keep up with your production line without compromising on accuracy. Look for machines that offer adjustable speed settings and can maintain consistent performance even at higher speeds. This flexibility allows you to optimize your production processes according to varying demand without sacrificing quality.

Consider the Ease of Use

A machine that is easy to operate can save you time and reduce the likelihood of errors. Look for machines with user-friendly interfaces, intuitive controls, and straightforward maintenance requirements. Training your staff to use the machine should be a quick and easy process. Additionally, consider the availability of customer support and technical assistance from the manufacturer. A machine that’s simple to use and well-supported will contribute to smoother operations and less downtime.

Check the Machine’s Flexibility

Flexibility in a vial labeling machine is key to adapting to different production needs. This includes the ability to handle various vial sizes, shapes, and label types. A flexible machine allows you to switch between different products with minimal downtime, which is especially important if you have a diverse product range. Additionally, consider whether the machine can be easily upgraded or modified to accommodate future changes in your production line, such as new vial designs or labeling requirements.

Assess the Durability and Build Quality

The build quality of your vial labeling machine directly impacts its longevity and reliability. Investing in a well-constructed machine, made from durable materials, ensures it can withstand the demands of your production environment. Look for machines with a robust frame, high-quality components, and a design that minimizes wear and tear. A durable machine will not only last longer but will also require fewer repairs and replacements, saving you money in the long run.

Evaluate the Machine’s Accuracy

Accuracy is paramount when it comes to vial labeling. Misaligned or improperly applied labels can lead to product recalls, compliance issues, and damaged brand reputation. Choose a machine that offers precise label placement and consistent performance. Advanced features, such as vision systems for label alignment or sensors for detecting label presence, can enhance the accuracy of the labeling process. Accurate labeling ensures your products meet regulatory standards and maintain a professional appearance.

Review the Machine’s Compliance with Regulations

Regulatory compliance is crucial in the pharmaceutical and medical industries, where vial labeling is often subject to stringent guidelines. Ensure that the machine you choose can comply with relevant regulations, such as those set by the FDA or other governing bodies. This includes the ability to print and apply labels with the required information, such as lot numbers, expiration dates, and barcodes. Compliance with these regulations not only ensures the safety and efficacy of your products but also protects your business from potential legal issues.

Consider the Total Cost of Ownership

While the initial purchase price is an important consideration, it’s essential to evaluate the total cost of ownership over the machine’s lifespan. This includes maintenance, repairs, energy consumption, and potential downtime. A cheaper machine may have higher operating costs in the long run, while a more expensive machine could offer better efficiency and lower maintenance needs. Consider the machine’s warranty, availability of spare parts, and the manufacturer’s reputation for reliability. A comprehensive cost analysis will help you make a financially sound decision that supports your business’s profitability.

Conclusion

Choosing the right automatic vial labeling machine is a critical decision that impacts your production efficiency, product quality, and overall business success. By carefully considering these 10 key points, you can make an informed choice that meets your specific needs and supports your long-term goals.